Oil return device and oil return method of compressor for dual-temperature air conditioner and air conditioning system

A technology for air conditioning systems and compressors, which is applied to compressors, heating and ventilation control systems, heating and ventilation safety systems, etc., can solve problems such as high cost and complicated control valve control, achieve low manufacturing costs, meet oil return and The effect of preventing air entrapment and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

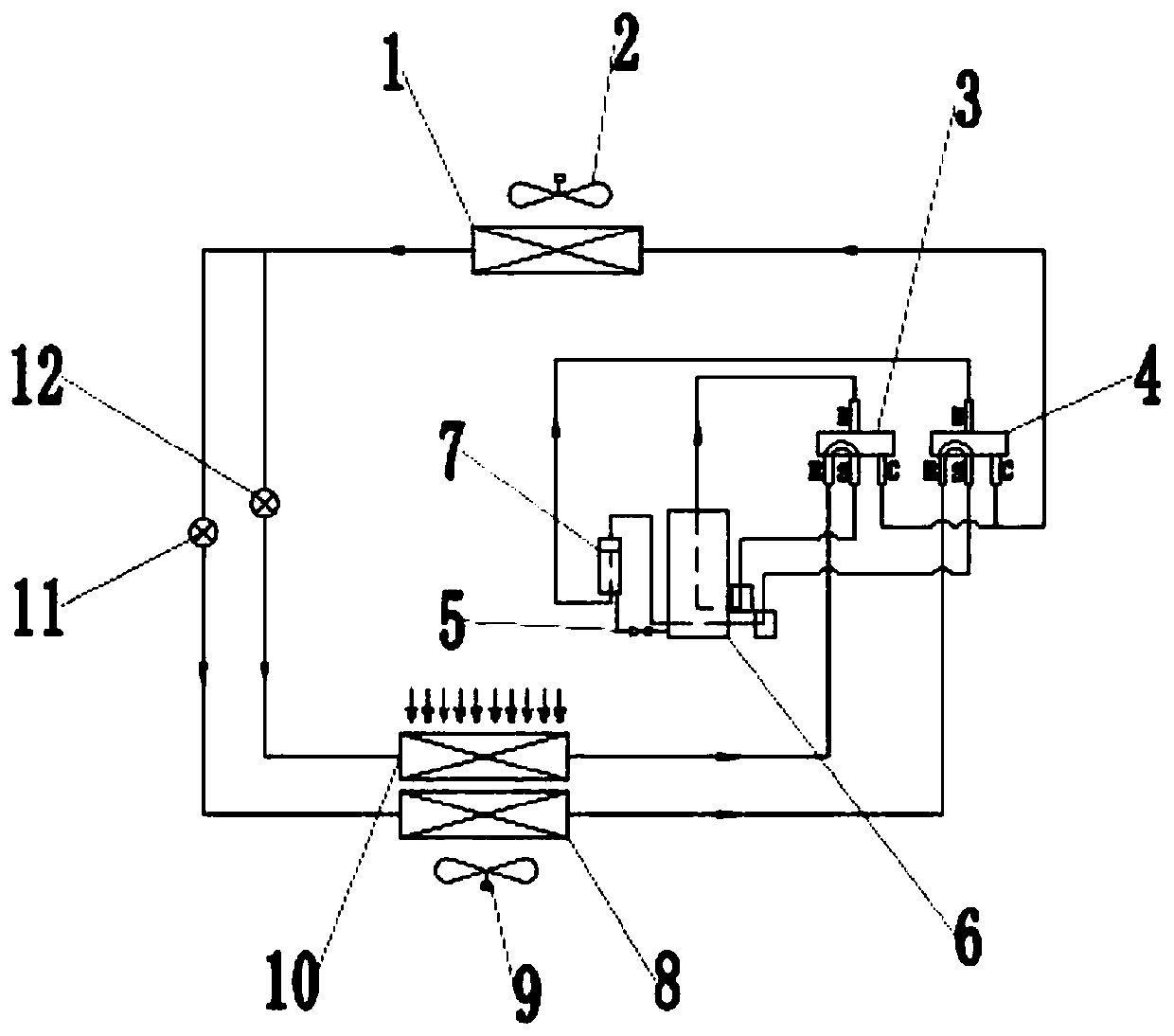

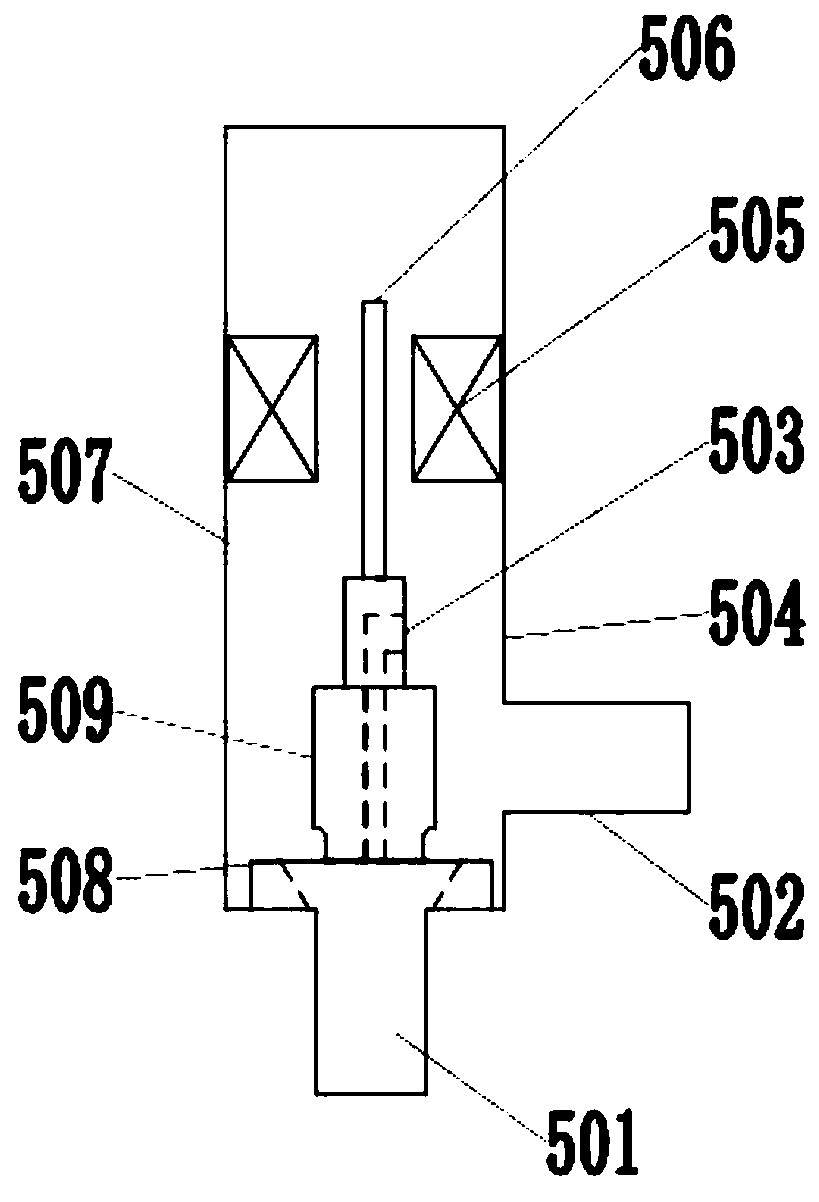

[0028] An air conditioning system with a double-suction double-row compressor 6, including an outdoor heat exchanger 1, a double-suction double-row compressor 6, an oil separator 7 and an indoor heat exchanger, the double-suction double-row compressor 6 and The oil separator 7 is connected, and the double-suction double-row compressor 6 is respectively connected with the first four-way valve 3 and the second four-way valve 4 through pipelines, and the oil separator 7 is communicated with the second four-way valve 4, The first four-way valve 3 is connected with the first indoor heat exchanger 10 and the outdoor heat exchanger 1 respectively, and the second four-way valve 4 is connected with the outdoor heat exchanger 1 and the second indoor heat exchanger 8 respectively, The outdoor heat exchanger 1 is respectively connected with the first indoor heat exchanger 10 and the second indoor heat exchanger 8 through pipelines.

[0029] The oil separator 7 is arranged at the second ex...

Embodiment 2

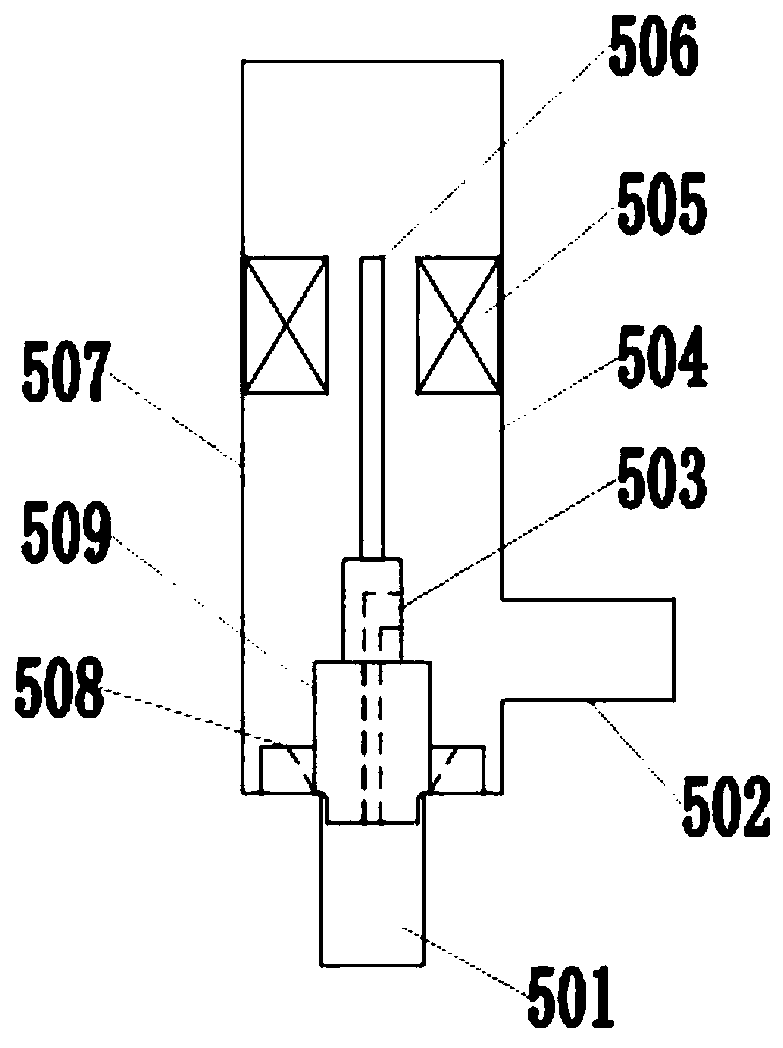

[0036] An air conditioning system with a double-suction double-row compressor 6, including an outdoor heat exchanger 1, a double-suction double-row compressor 6, an oil separator 7 and an indoor heat exchanger, the double-suction double-row compressor 6 and The oil separator 7 is connected, and the double-suction double-row compressor 6 is respectively connected with the first four-way valve 3 and the second four-way valve 4 through pipelines, and the oil separator 7 is communicated with the second four-way valve 4, The first four-way valve 3 is connected to the first indoor heat exchanger 10 and the outdoor heat exchanger 1 respectively, and the second four-way valve 4 is connected to the outdoor heat exchanger 1 and the second indoor heat exchanger 8 respectively, The outdoor heat exchanger 1 is respectively connected with the first indoor heat exchanger 10 and the second indoor heat exchanger 8 through pipelines.

[0037]The oil separator 7 is arranged at the second exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com