A field drying material tumbling machine

A material and motor technology, used in drying solid materials, lighting and heating equipment, drying and other directions, can solve the problems of uneven stirring, more dust, small working surface, etc., to achieve uniform and thorough tumbling, simple transmission process, power Easy-to-source effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

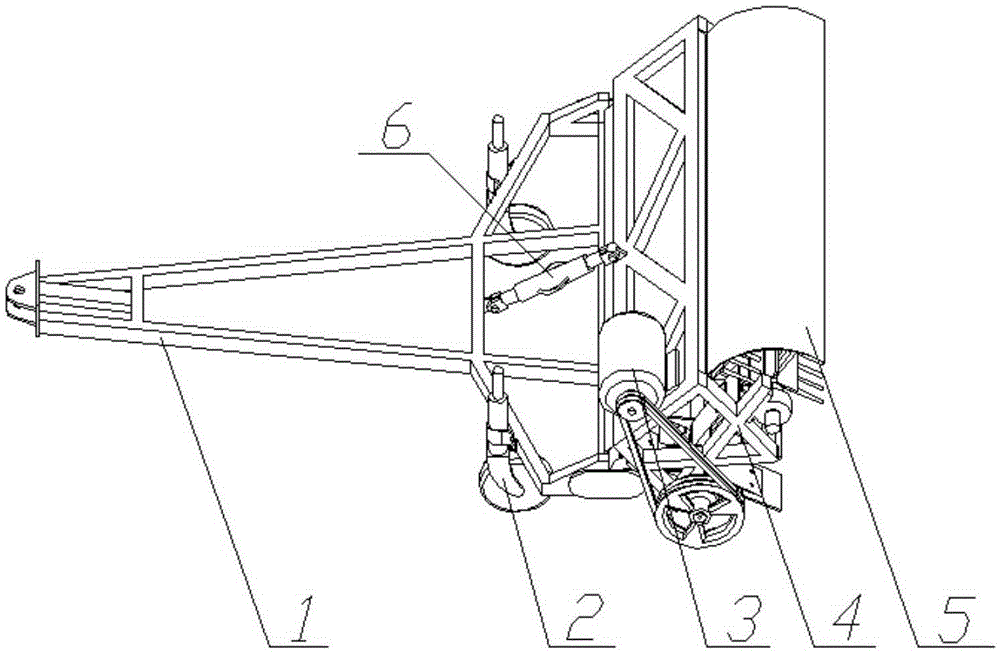

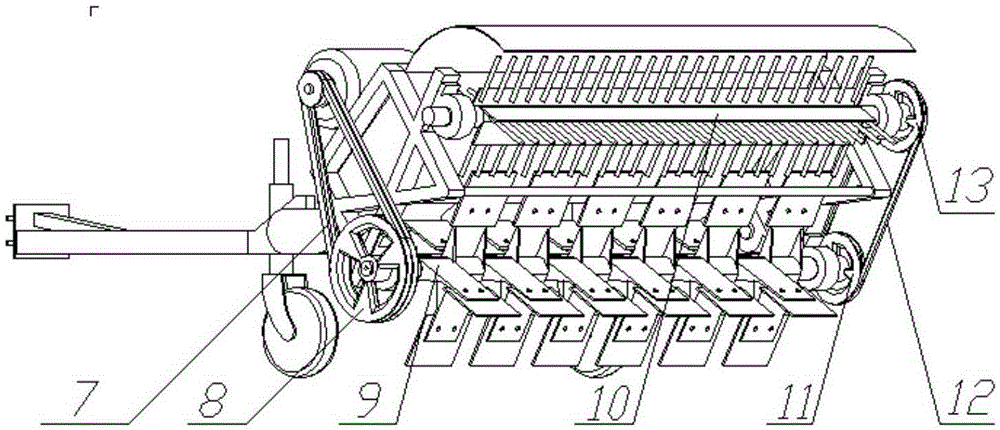

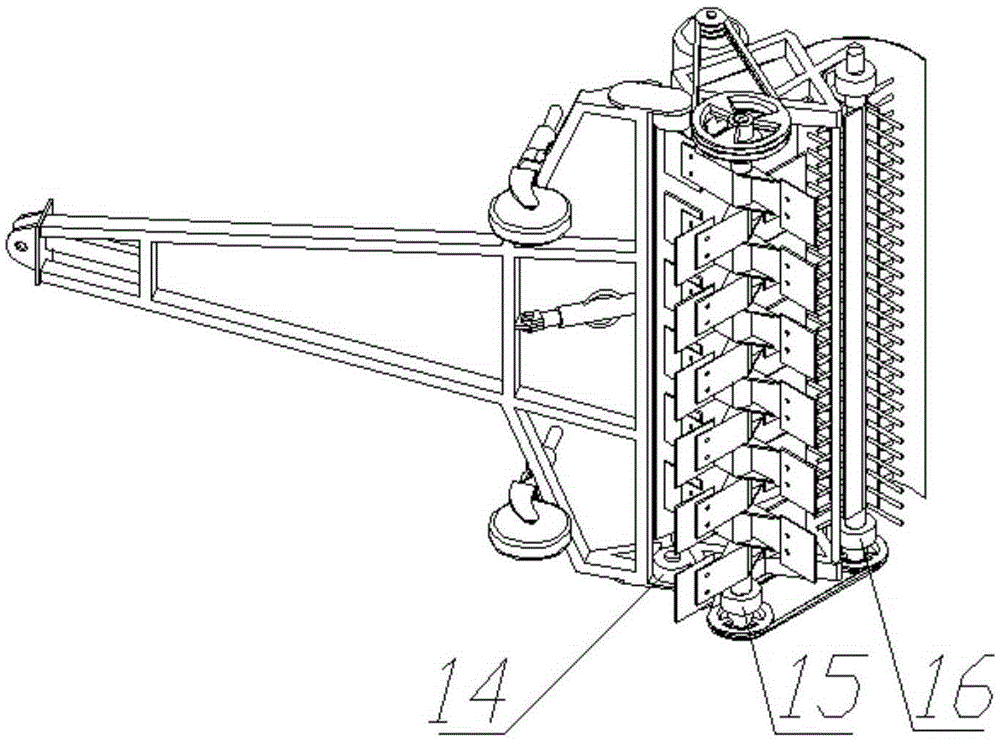

[0028] Such as Figure 1-3 As shown: the field drying material tumbling machine according to the present invention includes a bottom frame 1, a universal wheel 2, a motor 3, a movable frame 4, a material guide plate 5, a closed turnbuckle 6, a first belt 7, and a first pulley 8. Lower roller 9, upper roller 10, second pulley 11, second belt 12, third pulley 13, first bearing seat 14, second bearing seat 15, third bearing seat 16. The specific structure and connection method are:

[0029] The two sides of the underframe 1 are fixedly connected with a universal wheel 2 respectively, the underframe 1 and the movable frame 4 are connected with two bearing seats 13 through a closed turnbuckle 6, the motor 3, the material guide plate 5, and the lower roller 9 And the upper roller 10 is installed on the movable frame 4, the power of the lower roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com