Flexible base transmitting ejection loads

A flexible base and load technology, applied in the direction of launching devices, etc., can solve problems such as the impact of ejection safety, large load, and impact on the launch safety of the launch platform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

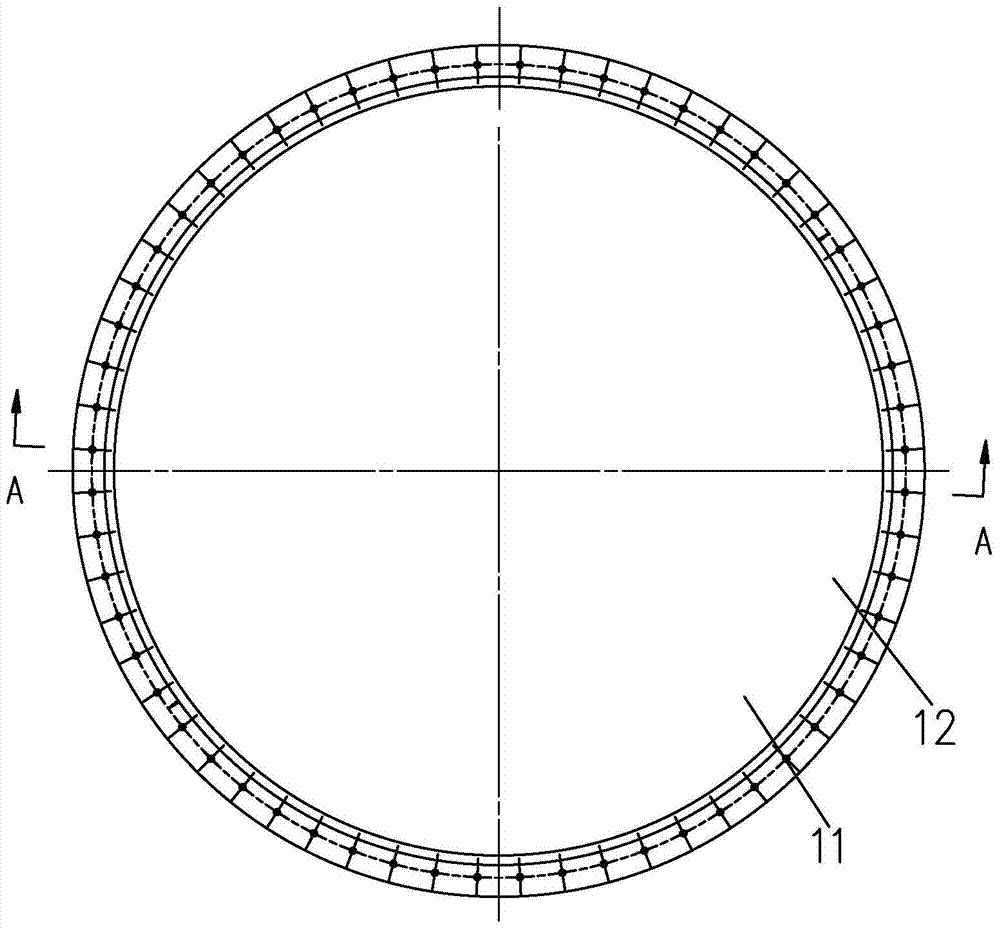

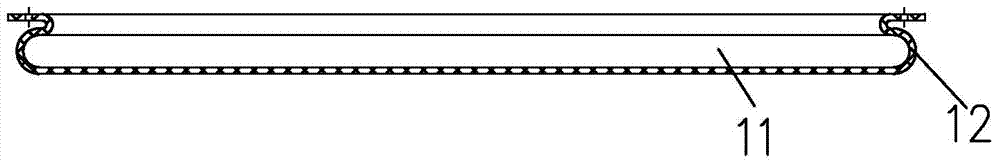

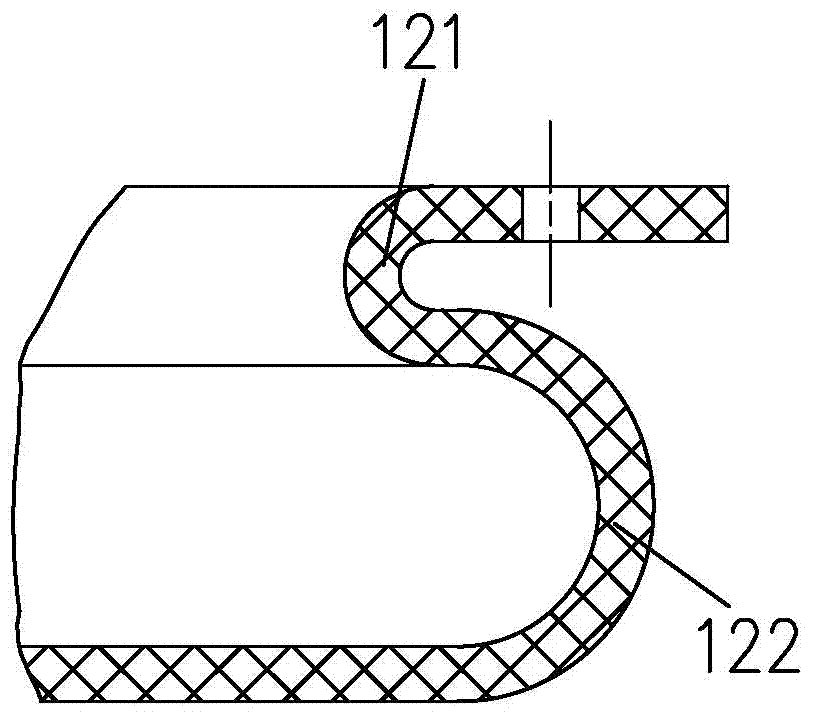

[0015] Such as figure 1 , 2 As shown, the flexible base of the present invention that transmits the ejection load includes a base plate 11 and a side wall 12, the thickness of the base plate 11 and the side wall 12 is 16mm, and the base plate 11 and the side wall 12 form a barrel shape, such as image 3 As shown, the longitudinal section of the side wall 12 is S-shaped, and the bottom plate 11 and the side wall 12 are all made of twelve layers of nylon / nitrile rubber adhesive tapes. The nitrile rubber sheet is calendered, and the laying angles of twelve layers of nylon / nitrile rubber cloth are 0°, 90°, 45°, -45°, 30°, -30°, 60°, - 60°, 15°, -15°, 75°, 75°, and a layer of nitrile rubber sheet is bonded outside the uppermost layer of adhesive tape and the lowermost layer of adhesive tape.

[0016] The radius of the upper semicircle 121 on the side wall 12 is 26mm, and the radius of the lower semicircle 122 is 41mm.

[0017] Such as Figure 4 As shown, the flexible base for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com