Splicing, butt joint and in-place method of large floating mats in natural rivers

A floating row, large-scale technology, used in transportation and packaging, ships, slipways, etc., can solve the problems of long construction period, large processing site area requirements, time-consuming and laborious processing, etc., to simplify processing, shorten construction period, and reduce processing sites. The effect of area demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

[0027] Such as Figure 1-Figure 6 As shown, the assembling, docking and positioning method of large-scale floating row in natural rivers described in the present invention comprises the following steps:

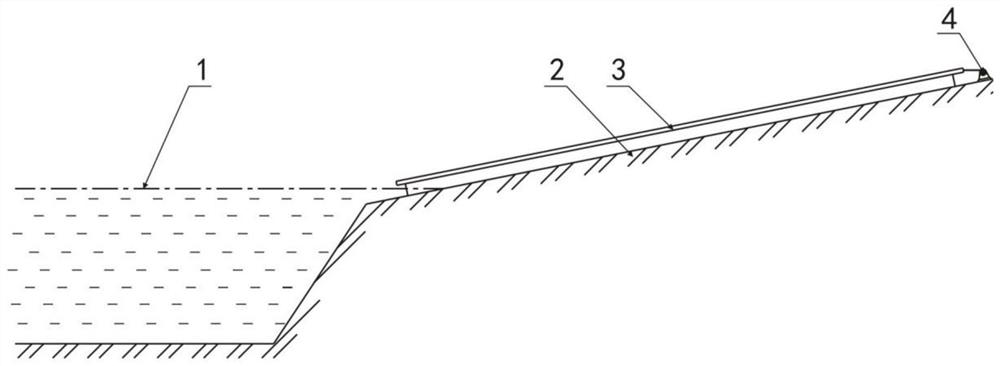

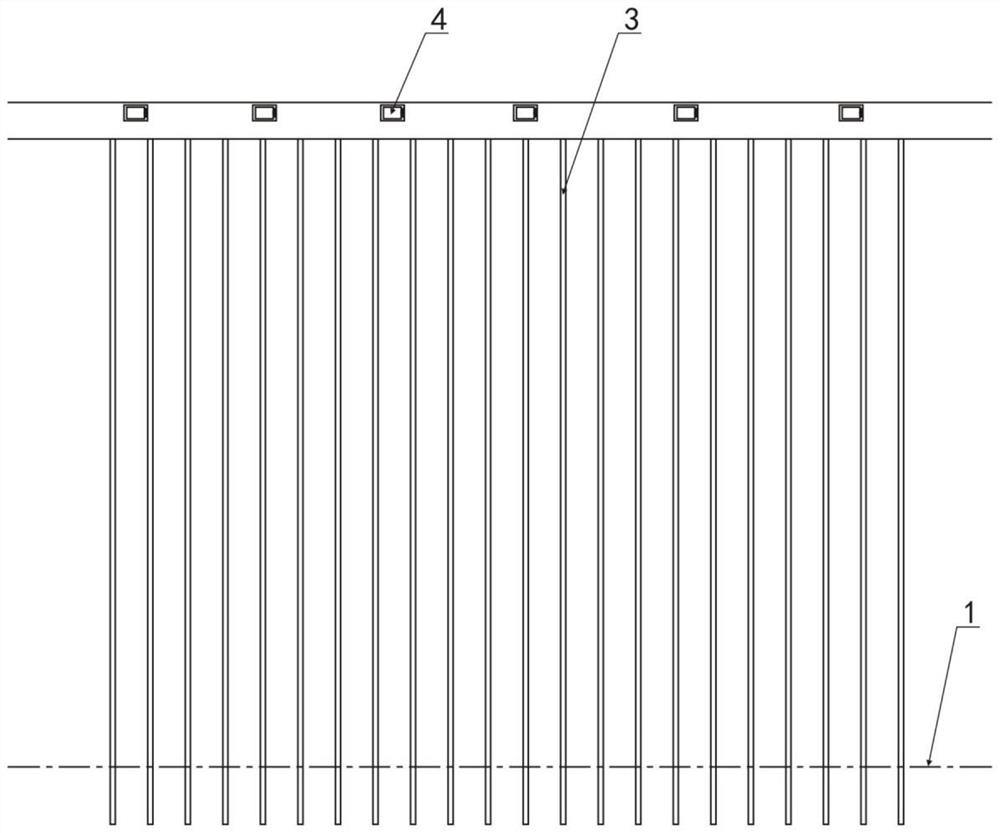

[0028] Step 1, such as figure 1 and figure 2 As shown, the processing site 2 is arranged on the river bank near the installation position of the floating row, and its size is not less than the size of the segmented floating row 6. The processing site 2 has a certain slope and the angle between it and the horizontal plane is 10-30 °, Preferably 20°, the side of the processing site 2 away from the water area is higher than the side close to the water area, and the side of the processing site 2 close to the water area is close to the river water surface line 1, and a plurality of slideway steel pipes 3 parallel to each other are laid on the processing site 2 as The slidew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com