Circuit board assembly

A circuit board assembly and flexible circuit board technology, which is applied to circuits, electrical components, parts of connecting devices, etc., can solve problems such as flipping up, poor interface contact, electronic function failure, etc., and achieves enhanced electrical connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

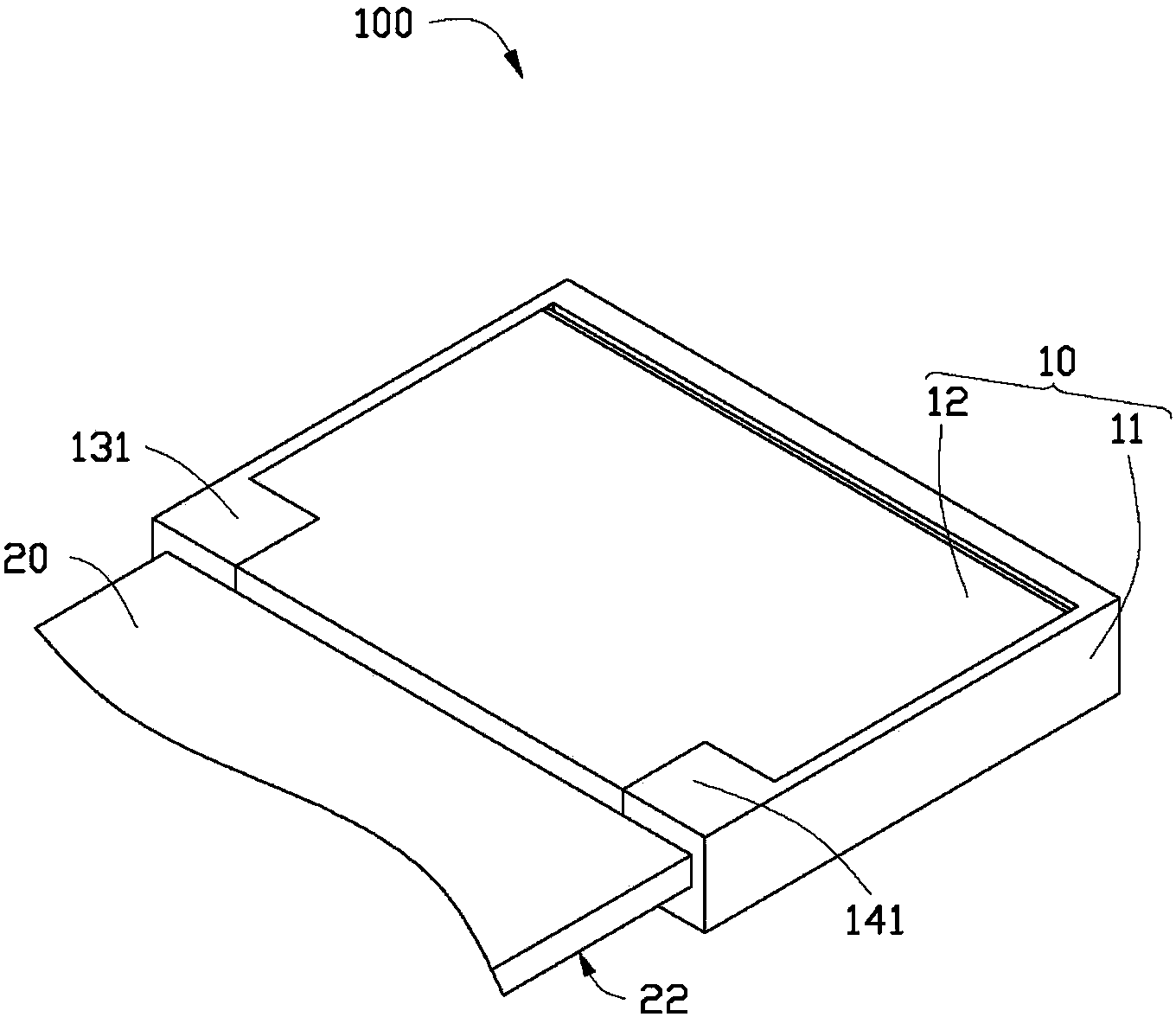

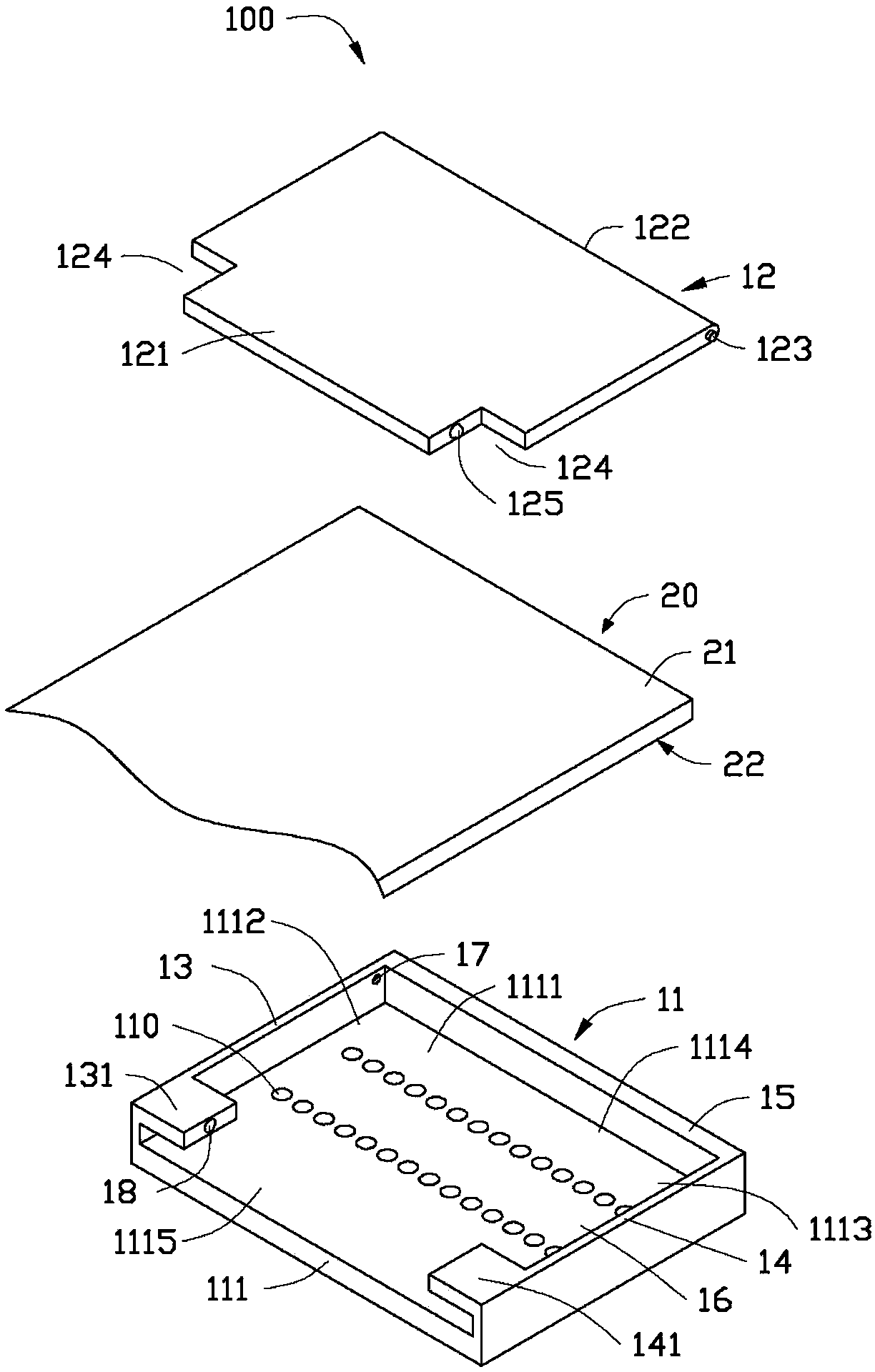

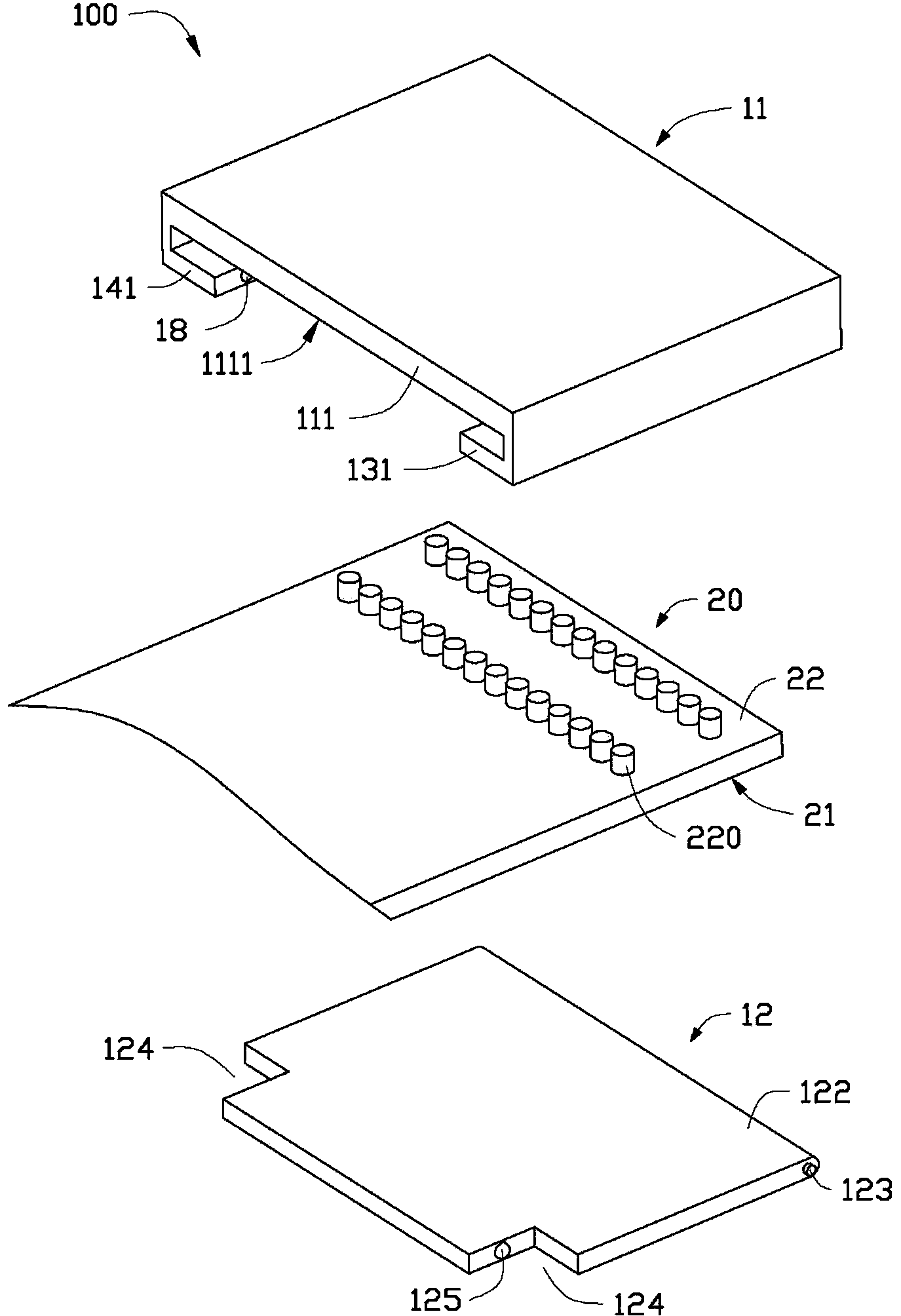

[0013] Please also refer to Figure 1-3 The circuit board assembly 100 provided by the present invention includes an interface portion 10 and a part of the flexible circuit board 20 accommodated in the interface portion 10 and electrically connected to the interface portion 10 .

[0014] The interface portion 10 includes a connecting piece 11 and a cover 12 covering the connecting piece 11 .

[0015] The connector 11 includes a base plate 111 and a plurality of flanges. The substrate 111 includes a carrying surface 1111 . A plurality of electrical interfaces 110 are formed on the carrying surface 1111 . The plurality of electrical interfaces 110 are arranged in parallel in two rows. In this embodiment, the carrying surface 1111 is a rectangle, which includes a first side 1112, a second side 1113 away from the first side 1112, a third si...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap