Control device for internal combustion engine

A technology of a control device and an internal combustion engine, which is used in engine control, internal combustion engine testing, internal combustion piston engines, etc., can solve problems such as difficult internal combustion engines and high compression ratios, and achieve the effect of reducing computational load and achieving high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

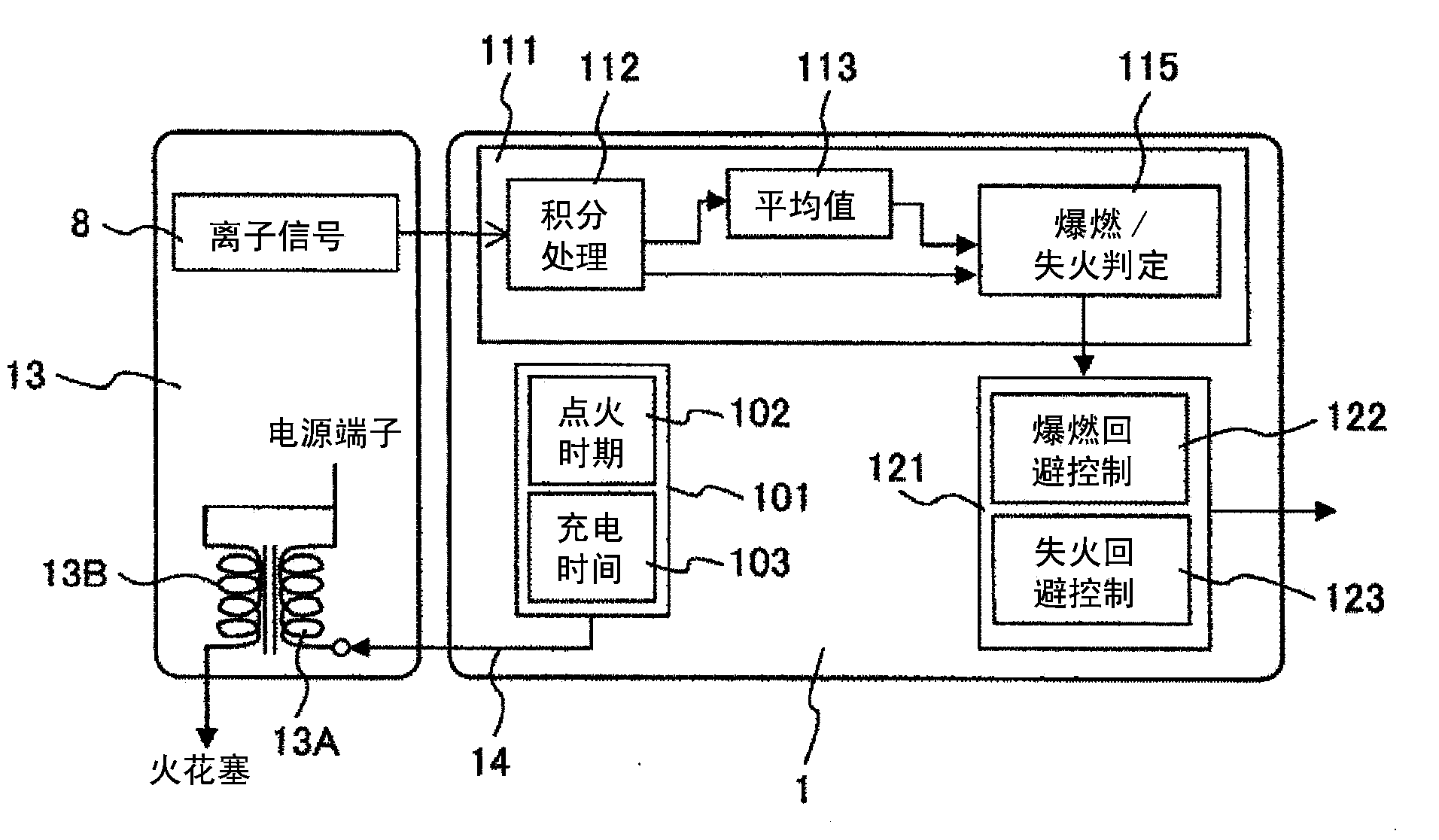

[0050] figure 2 It is a diagram showing processing blocks of input and output signals of a control device for an internal combustion engine (hereinafter, simply referred to as a control device) according to an embodiment of the present invention. In the control device 1, based on input signals from various sensors, the ignition timing calculation module 102 calculates the ignition timing, and the charging time calculation module 103 calculates the energy required for the ignition, that is, the charging time of the primary current. An ignition signal 14 in which the ignition timing and charging time are paired is output to the ignition coil 13 .

[0051] The ignition coil 13 is composed of a primary coil 13A and a secondary coil 13B. The upper end of the primary coil 13A is connected to a power source, and the lower end of the primary coil 13A is configured to receive an ignition signal 14 . Detailed descriptions of generally used transistors and other drive circuits are omit...

Embodiment 2

[0098] Next, other embodiments of the present invention will be described in detail using the drawings. Figure 9 It is a configuration in which the ion signal integration processing module 112 of the ion signal processing unit 111 shown in the first embodiment is changed to the ion signal peak detection module 116 .

[0099] The operation of this second embodiment is basically the same as that of the first embodiment, but differs in that the ion signal peak detection module 116 is used as described above.

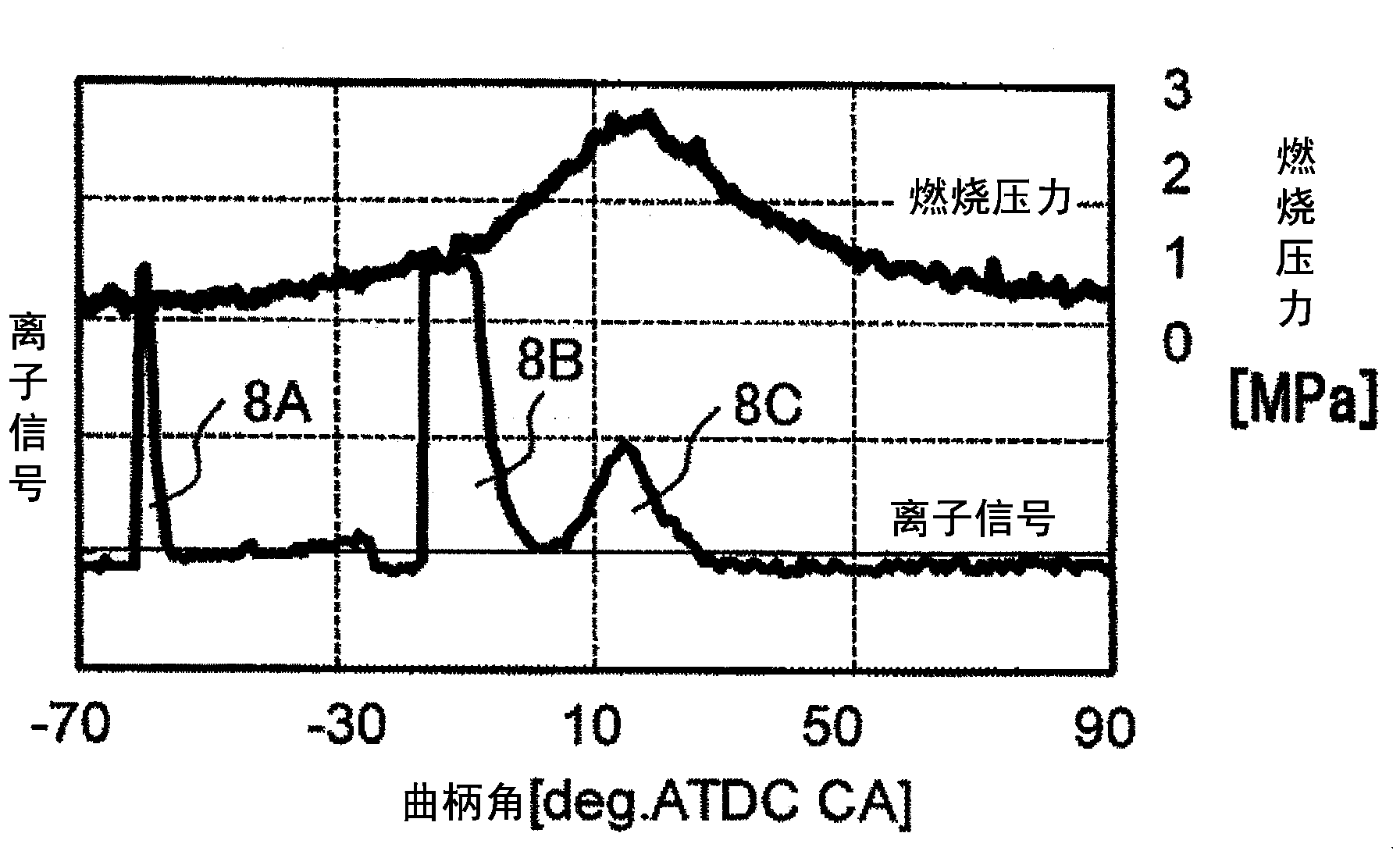

[0100] Next, if the action is simply explained, then Figure 10 for with Figure 4 The waveform of the same ion signal shows the relationship between the ignition signal 14 and the ion signal 8 . Ignition signal 14 is input at time T1 to start charging for accumulating ignition energy in primary coil 13A. image 3 The noise waveform described in is the first peak 8A. This peak 8A is not used for detection of knocking or misfire because it is noise caused by the ignitio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap