Aluminum strip edge roller device

An aluminum strip and edge grinding technology, applied in the field of aluminum strip finished product processing equipment, can solve the problems of coiled material forming a tower shape, the coil can not have burrs, unevenness, etc., to improve the burr and curling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below through specific embodiments and accompanying drawings.

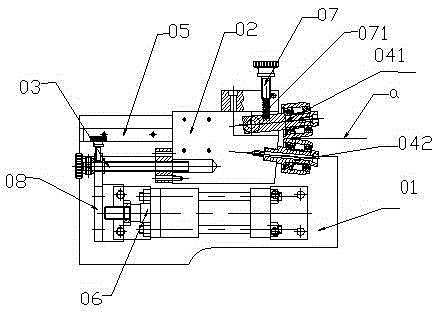

[0011] An aluminum strip edging roller device, which includes a fixed frame 01, a first movable frame 02, and an edging roller capable of trimming the edge of the aluminum strip a located inside the frame, the fixed frame 01 is provided with a horizontal rail 05 along the longitudinal direction, and the aluminum strip edge roller device includes positioning screws 03 that can push the first movable frame 02 to slide and lock along the rail 05; the edge rollers are installed on The inner side end of the first movable frame 02, the described edge pressing rollers include the upper pressing roller 041 and the lower pressing roller 042, and the roller surface of the upper pressing roller 041 and the lower pressing roller 042 form a gap towards the inside. The mouth is opened, and the roots are in contact with each other to form a beading surface; the aluminum stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com