Method of Improving Burr Condition on Flexible Substrate

A flexible substrate, burr technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as affecting ODF, high burr, and product yield decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

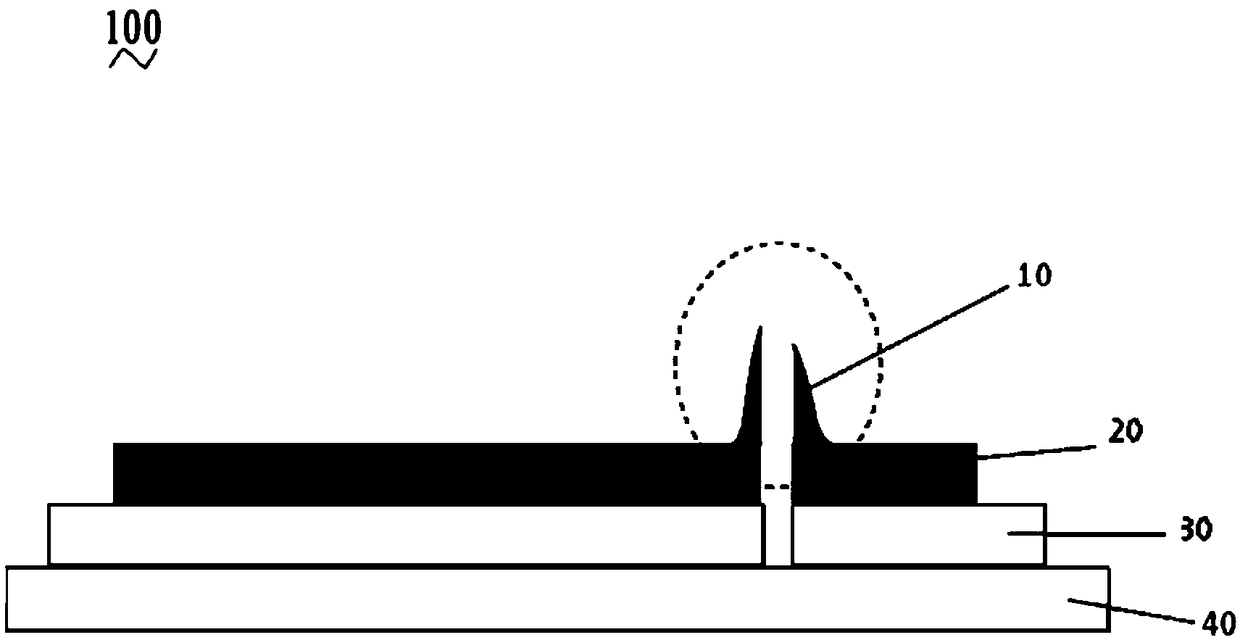

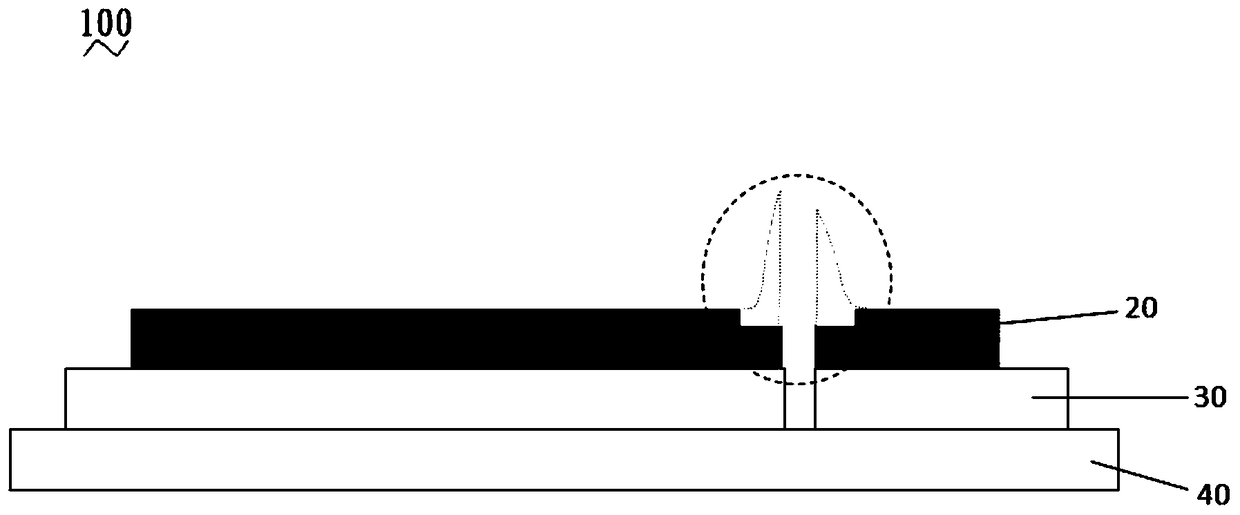

[0038] The flexible substrate in this embodiment is a CF substrate. After the flexible substrate is pre-cut and before the burrs are not improved, its structure is as follows figure 1 As shown, the flexible substrate includes a substrate, a flexible substrate and an insulating layer. The substrate and the insulating layer are respectively attached to both sides of the flexible substrate. The insulating layer is made of epoxy resin material, and the thickness of the insulating layer is 10 μm. The pre-cutting is to cut the flexible substrate and the insulation layer, and the cutting place forms a cutout, and after cutting, the insulation layer produces burrs at the cutout place.

[0039] Using dry etching to improve the cutting burr of the flexible substrate includes the following steps:

[0040] providing the above-mentioned flexible substrate;

[0041] Coat the burr side of the flexible substrate with photoresist to form a photoresist surface. The photoresist surface is provi...

Embodiment 2

[0046] The flexible substrate in this embodiment is a CF substrate. After the flexible substrate is pre-cut and before the burrs are not improved, the flexible substrate includes a base material, a flexible underlayment and an insulating layer. The base material and the insulating layer are respectively attached to both sides of the flexible underlayment. , the insulating layer is made of acrylic resin material, and the thickness of the insulating layer is 12 μm. The pre-cutting is to cut the flexible substrate and the insulation layer, and the cutting place forms a cutout, and after cutting, the insulation layer produces burrs at the cutout place.

[0047] Using dry etching to improve the cutting burr of the flexible substrate includes the following steps:

[0048] providing the above-mentioned flexible substrate;

[0049]Coat the burr side of the flexible substrate with photoresist to form a photoresist surface. The photoresist surface is provided with an exposure area and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com