Patents

Literature

55results about How to "The follow-up process is smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A method for manufacturing high-strength, high-modulus, low-shrinkage polyester industrial yarn

ActiveCN102797054BReduce disturbanceReduce the temperatureFilament/thread formingMonocomponent polyesters artificial filamentYarnFiber

The invention discloses a manufacturing method of a high-strength, high-modulus and low-shrinkage polyester industrial yarn. The manufacturing method comprises the processes of preparation of a highly viscous melt polyester raw material, metering, spinning, cooling, oil applying, drawing, heat shaping and winding formation; the cooling comprises slow cooling, precooling, cooling in an air free zone and air blast cooling in sequence; the precooling part uses a driven hollow-out successive annular strip. Through the introduction of a precooling device, irregularity caused by tow shaking due to move-down of a curing point of a fiber is reduced, the linear density deviation is controlled within a lower range, and orientation and crystallization of an as-spun fiber are reduced, so that the high-strength, high-modulus and low-shrinkage polyester industrial yarn is obtained; and the high-strength, high-modulus and low-shrinkage polyester industrial yarn has the advantages of high breaking tenacity, high initial modulus, low linear density deviation, low breaking elongation and lower dry-heat shrinkage rate and can be used for preferably satisfying requirements on application.

Owner:JIANGSU HENGLI CHEM FIBER

Silver nanowire array electrode and its preparation method and application

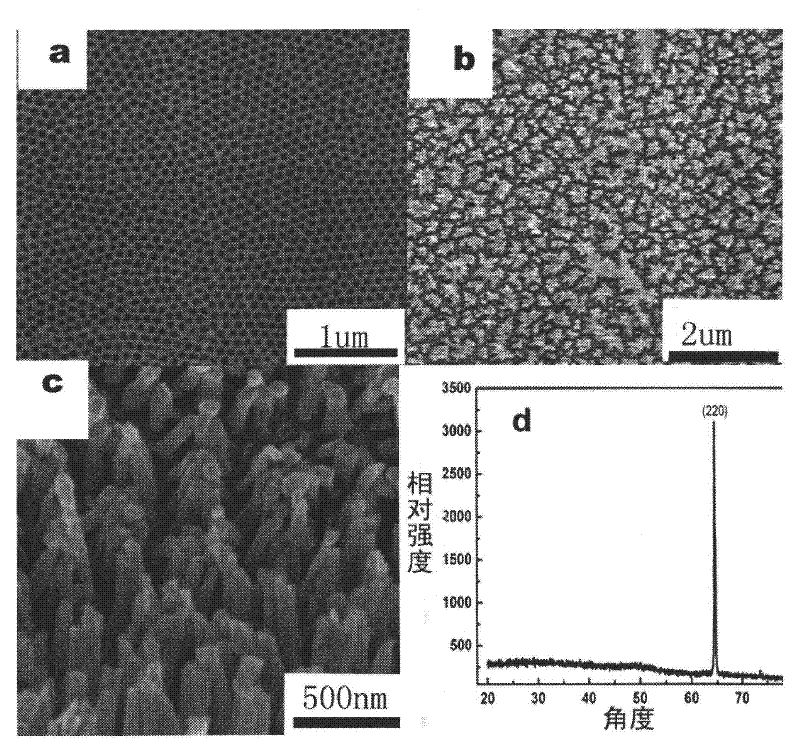

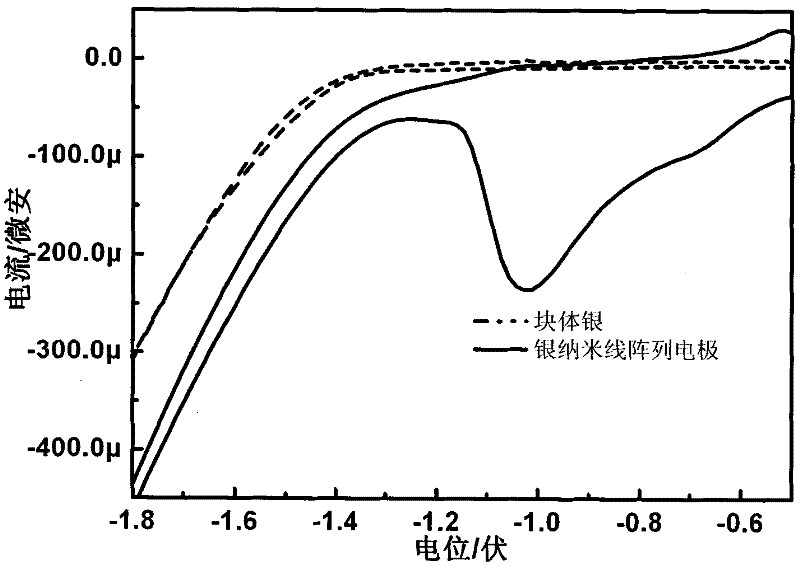

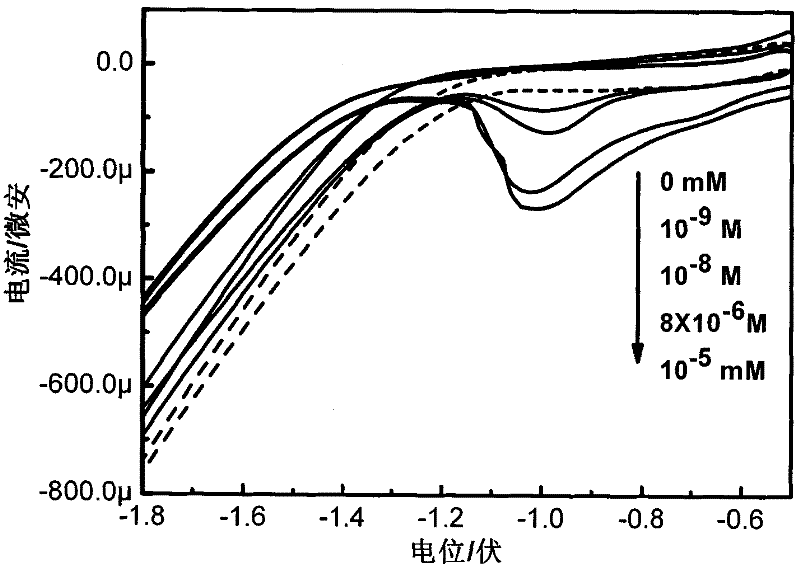

InactiveCN102267682AGood arrayUnbreakableIndividual molecule manipulationVacuum evaporation coatingElectrolysisSilver nanowires

The invention discloses a silver nanowire array electrode, a preparation method and application thereof. The electrodes are silver nanowires forming an array with a diameter of 50-70nm and a wire length of 250-350nm. The bottom of the array is a silver film of 130-170nm and a copper film of 0.5-1mm; the method is to use a secondary anode on the aluminum sheet first Oxidation method to obtain a through-hole alumina template with a pore diameter of 50-70nm, and then use the ion sputtering method to vapor-deposit a silver film on one side of the alumina template, and then place the alumina template with a silver film on one side in a silver electrolysis solution, use the electrodeposition method to electrodeposit at a constant voltage of 0.08 to 0.12V for 1 to 5 minutes, then place it in the copper electrolyte, use the electrodeposition method to electrodeposit 2.5 to 3.5 at a current of 8 to 12mA / cm2 h, after that, put the aluminum oxide template with silver nanowires in the hole, one side covered with silver film and copper film in sequence, in acid solution or strong alkali solution to corrode the aluminum oxide template, and make silver nanowire array electrode. Array electrodes can be used as sensitive elements for trace detection or reduction of halogenated organic compounds.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Manufacturing method for high-modulus low-shrinkage PET industrial yarn

ActiveCN102797057AReduce disturbanceReduce the temperatureFilament/thread formingMonocomponent polyesters artificial filamentYarnFiber

The invention discloses a manufacturing method for high-modulus low-shrinkage PET industrial yarn, and the technological process of the method is as follows: hyperviscous melting to polyester fiber raw materials, metering, spinning, cooling, oil applying, stretching, hot shaping and reeled forming, wherein the cooling process sequentially comprises four parts including slow-cooling, pre-cooling, calm zone cooling and blow cooling, and the pre-cooling part adopts a passive hollow ring-shaped belt device. Through the introduction of the pre-cooling device, the irregularity caused by tows quivering produced under the down moving of a solidification point of fiber can be reduced, the deviation ratio of linear density can be controlled within a lower range, the purpose of reducing orientation and crystallization of embryo fiber is achieved, finally high-modulus low-shrinkage PET industrial yarn can be obtained, the high-modulus low-shrinkage PET industrial yarn has the advantages of high modulus, low dry heat shrinkage percentage, low breaking elongation and low linear density deviation ratio, and practical application can be well met.

Owner:JIANGSU HENGLI CHEM FIBER

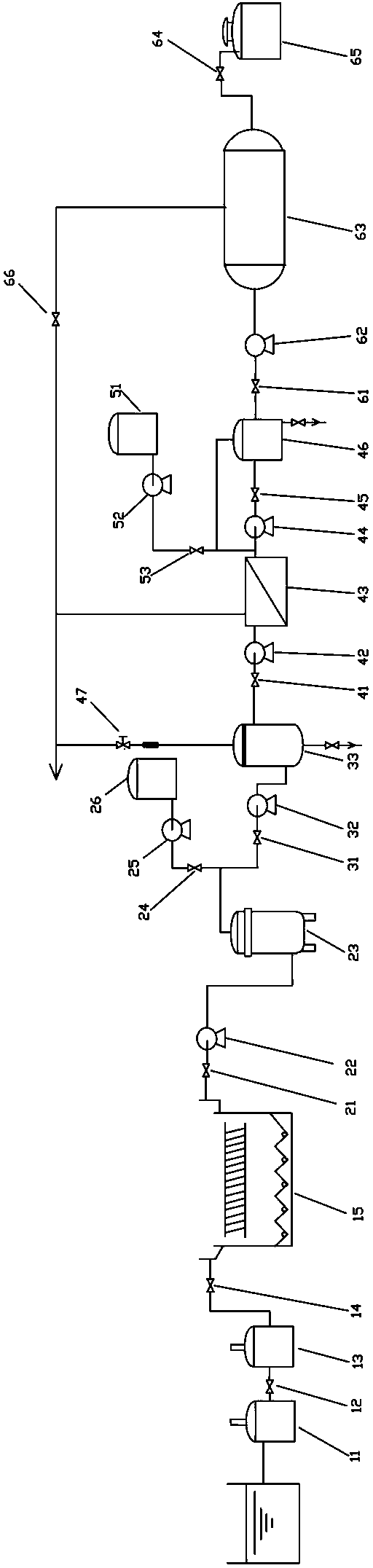

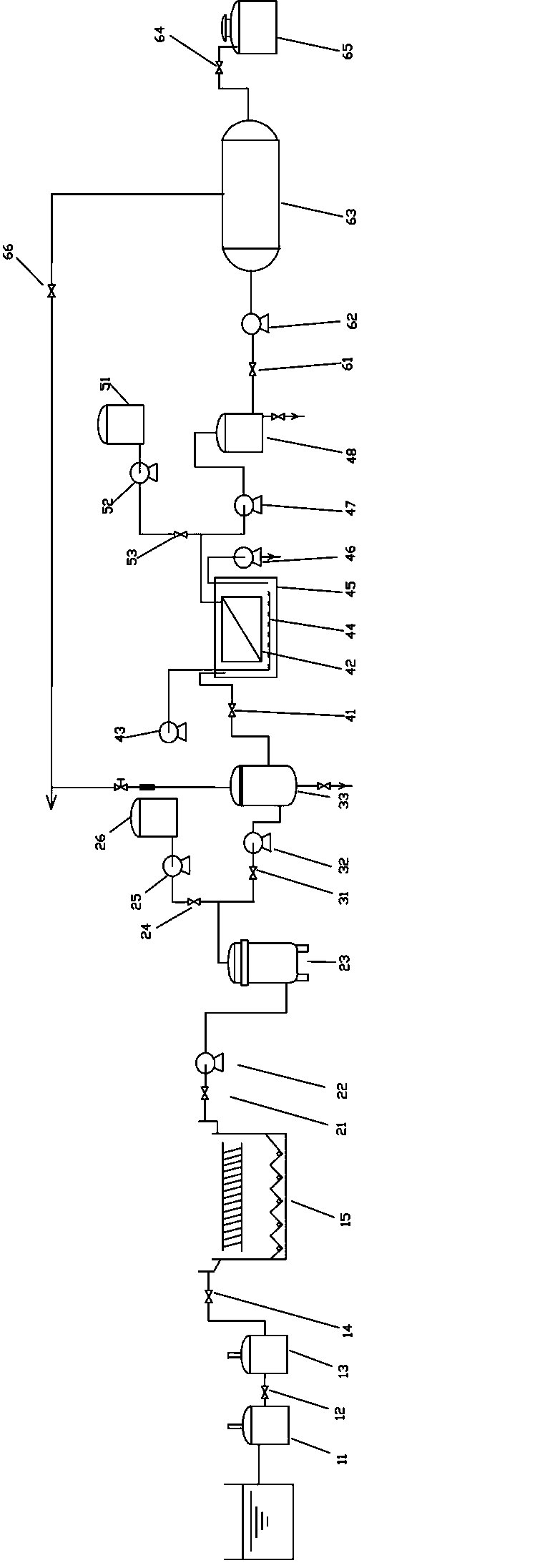

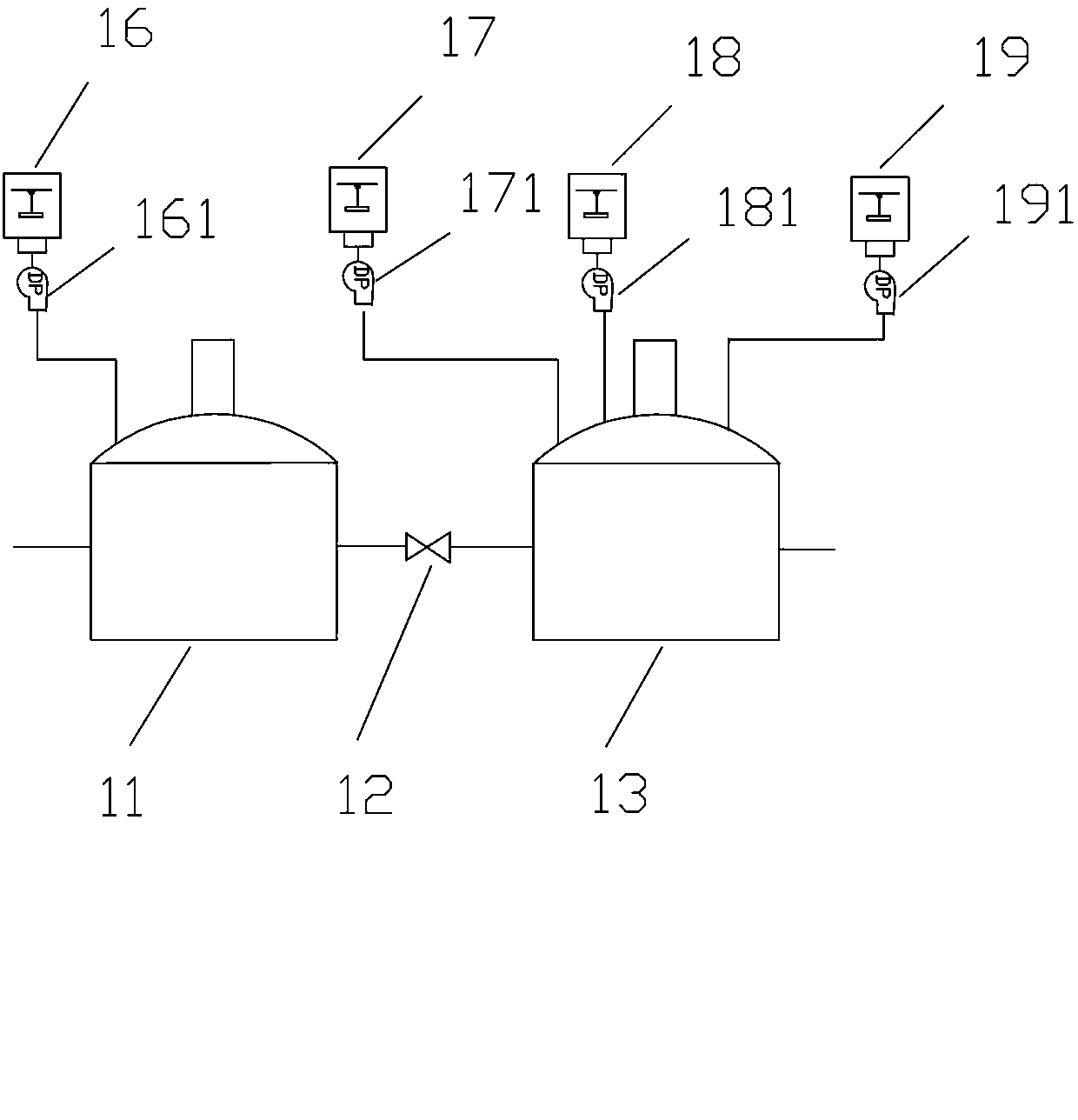

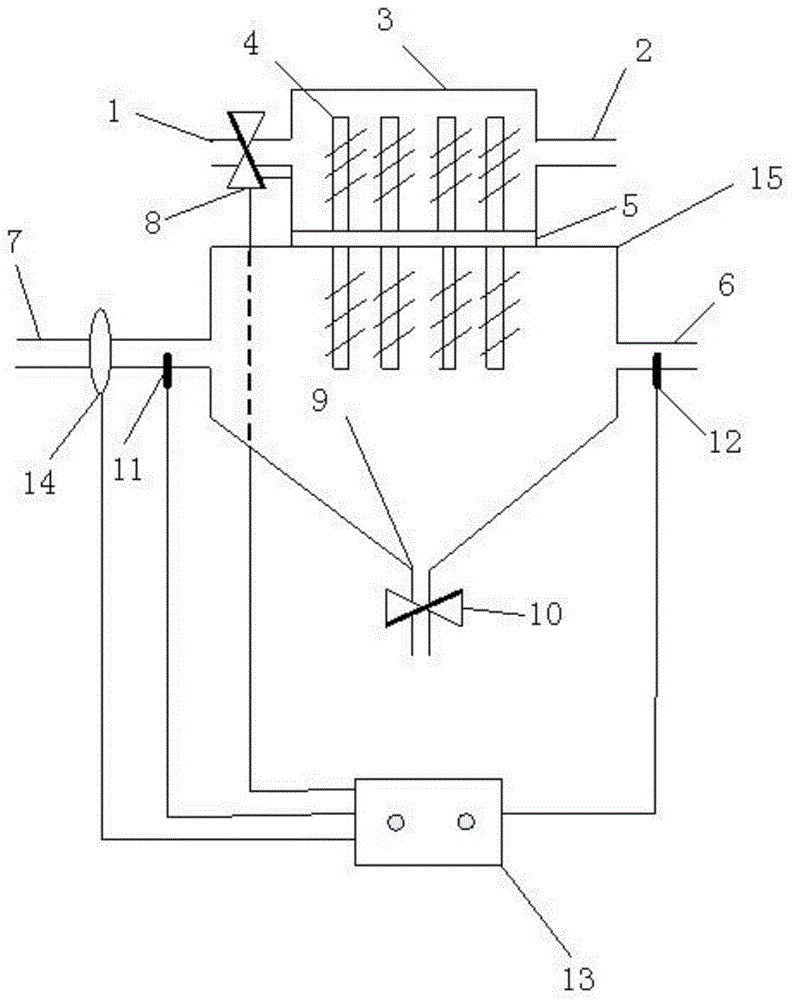

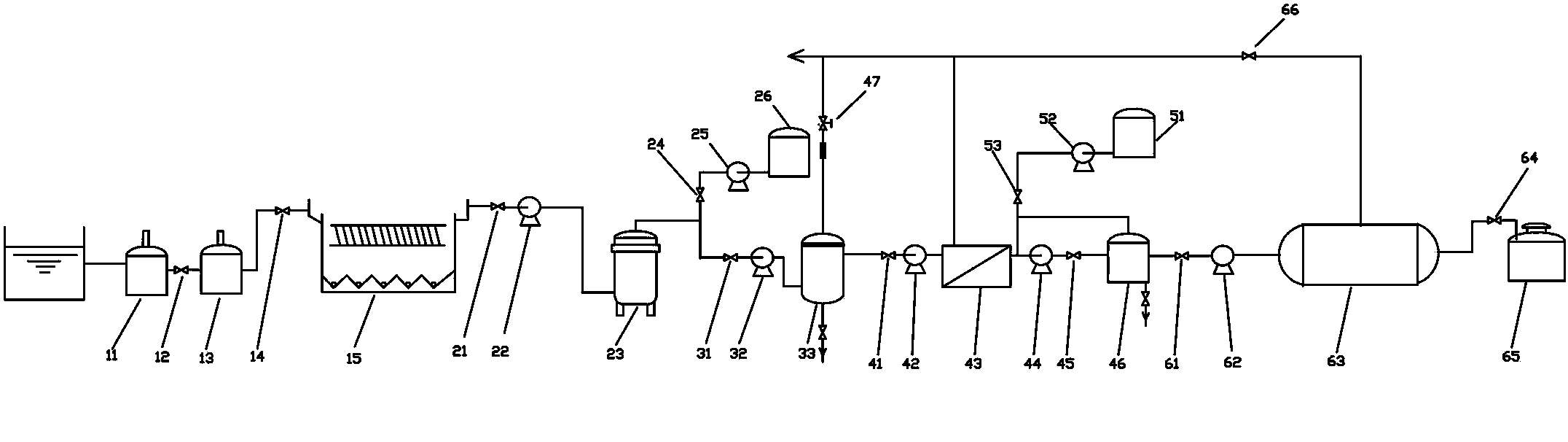

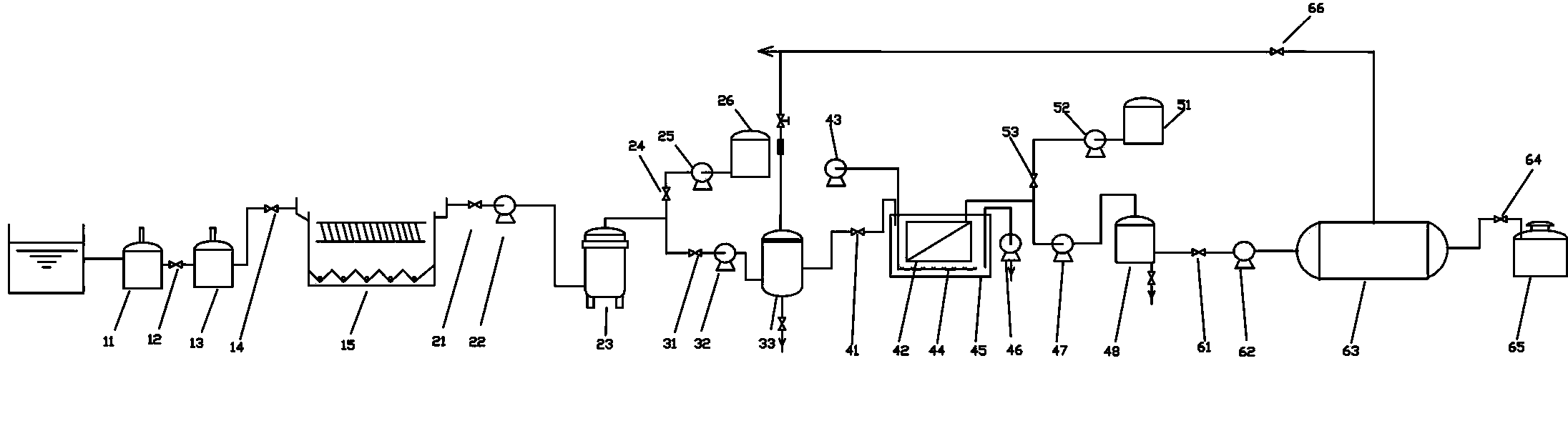

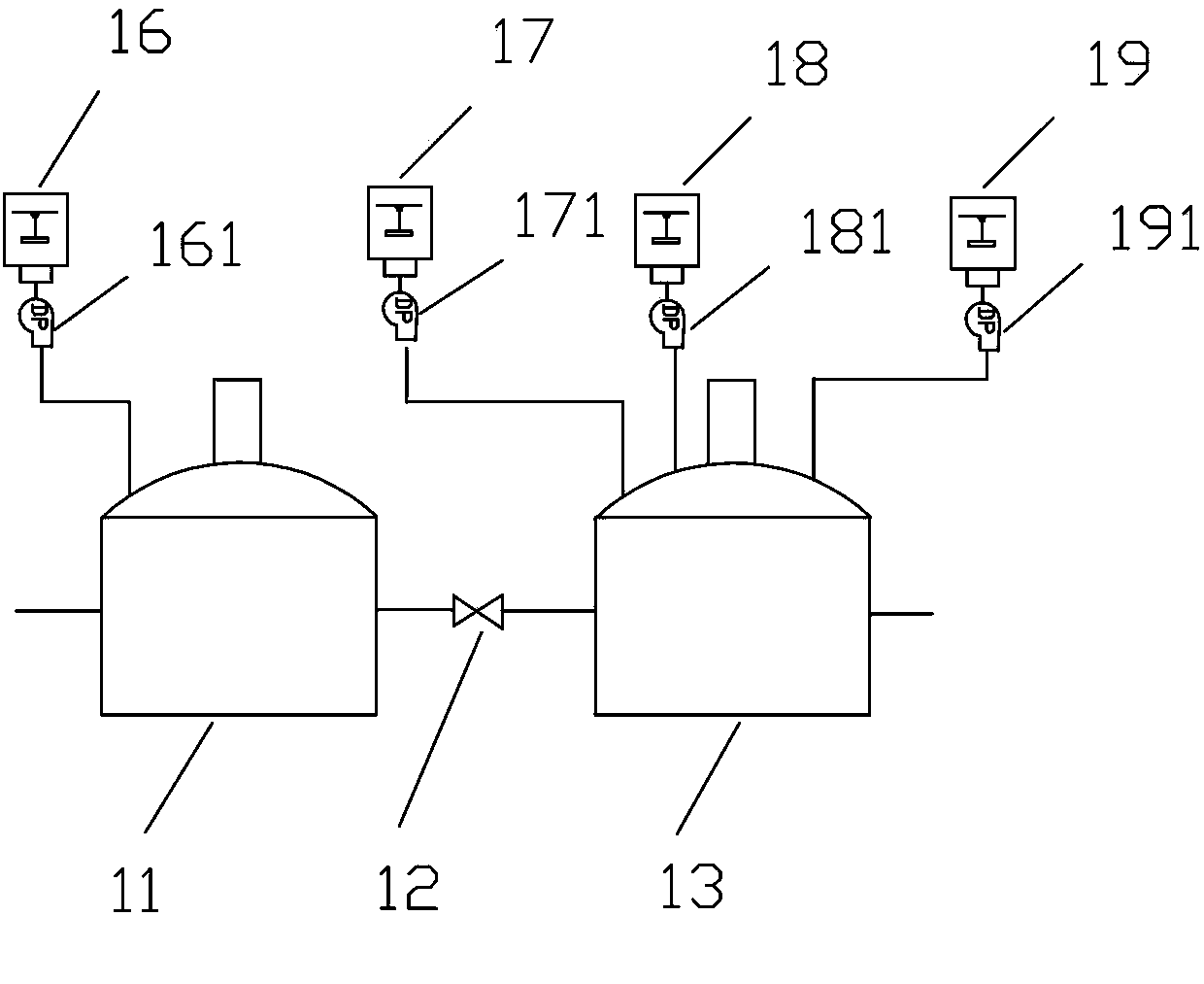

Recycling device used for papermaking advanced treatment wastewater and based on chemical decalcification

InactiveCN103253838AEmission reductionReduce wasteGeneral water supply conservationMultistage water/sewage treatmentElectrolysisMembrane technology

The invention discloses a recycling device used for papermaking advanced treatment wastewater and based on chemical decalcification. The recycling device comprises a chemical decalcification system, a filter system, an electrolysis system, a membrane separation system and a desalting system, wherein the chemical decalcification system is equipped with a dosing system, and the membrane separation system is one of an ultrafiltration system and an MBR (Membrane Bio-Reactor) system. The recycling device combines a chemical decalcification technology, an electrochemical technology and a membrane technology, and 70-85% of the papermaking advanced treatment wastewater can be regenerated and recycled after treated, so that wastewater discharge is reduced; environmental pollution due to the wastewater is avoided; waste of a water resource is reduced; the cost of the regenerated circulating water can be lower than that of tap water; and the recycling device is economical and reasonable, generates better economic benefits, lowers a water consumption index and a wastewater discharge index per ton of paper greatly, and raises economic and technical indexes of an enterprise.

Owner:BOYING XIAMEN SCI & TECH

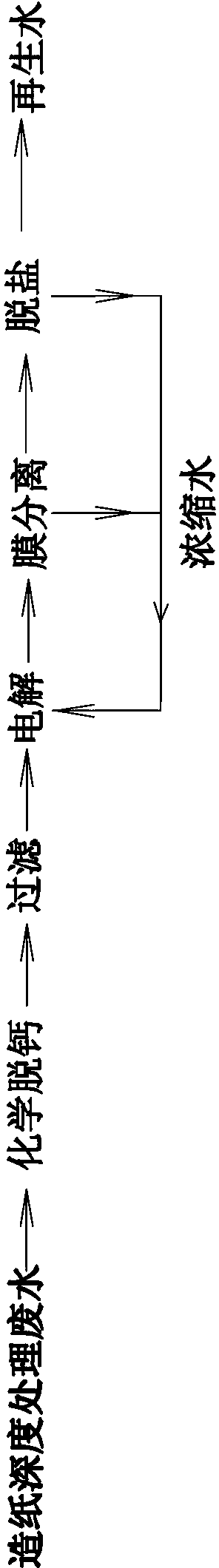

Recycling method of papermaking advanced treatment wastewater based on chemical decalcification

InactiveCN103265133AOvercoming processingOvercome costsGeneral water supply conservationMultistage water/sewage treatmentElectrolysisDesalination

The invention discloses a recycling method of papermaking advanced treatment wastewater based on chemical decalcification. The recycling method comprises the following steps of chemical decalcification, filtering, electrolysis, membrane separation (ultra-filtration / MBR) and desalination. By combination of a chemical decalcification technology, an electrochemical technique and a membrane technology, 70-85% of papermaking advanced treatment wastewater can be recycled after being processed. Thus, wastewater emission is reduced; environmental pollution of the wastewater is avoided; waste of water resources is reduced; and the cost of regenerated circulating water is lower than the price of running water. Therefore, the recycling method is economical and reasonable; good economic benefit is generated; water consumption targets of tons of paper and wastewater discharge targets are greatly reduced; and the economic and technical indexes of enterprises are improved.

Owner:BOYING XIAMEN SCI & TECH

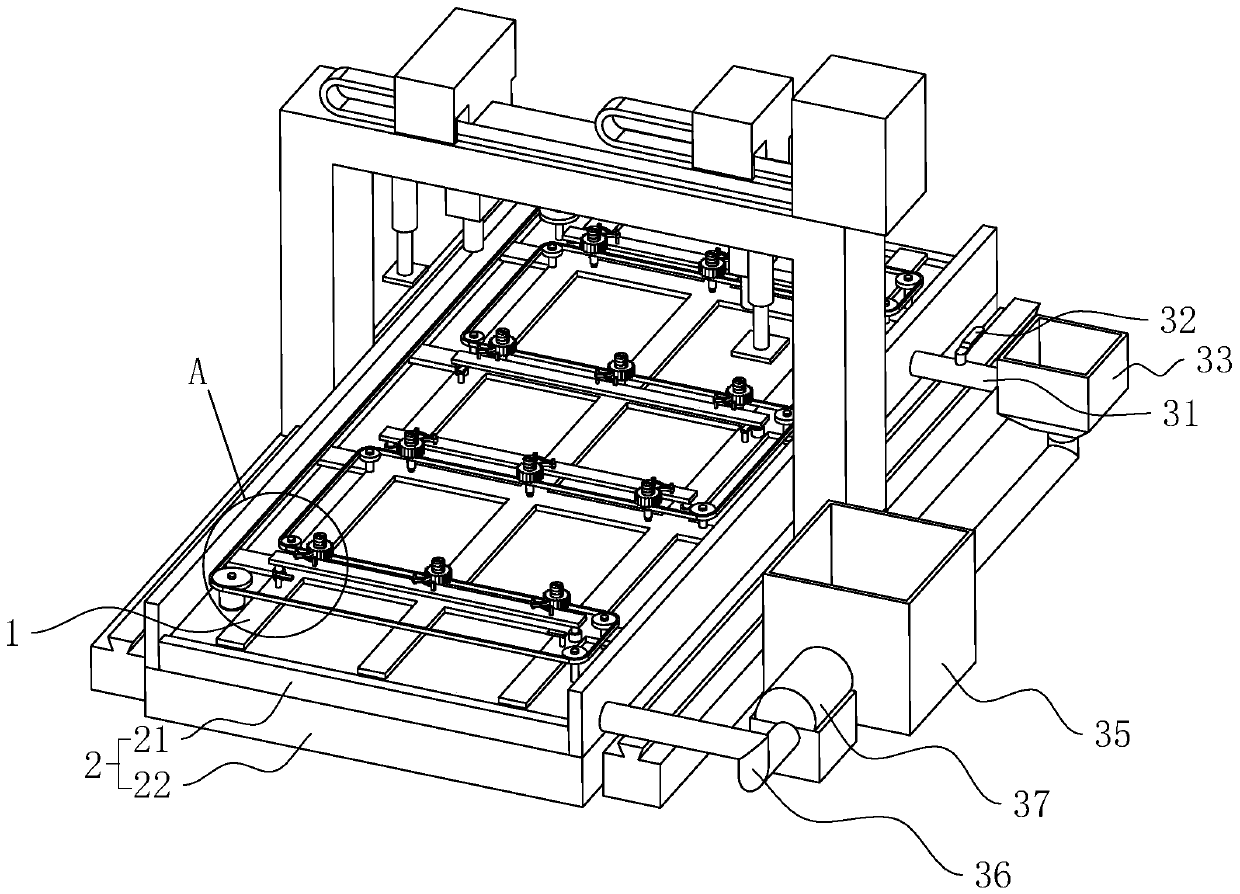

Non-knife-mark die cutting method for polyimide film product and die cutting device

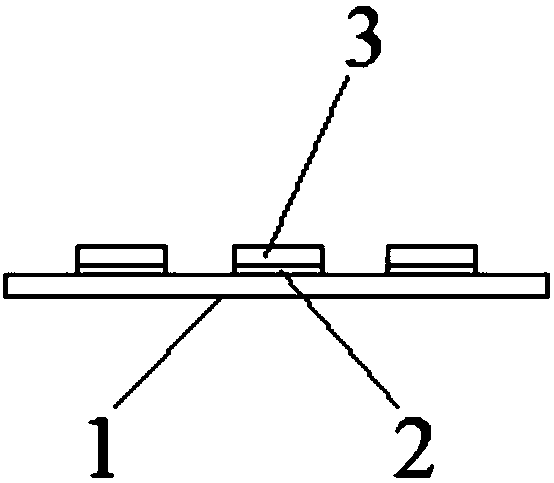

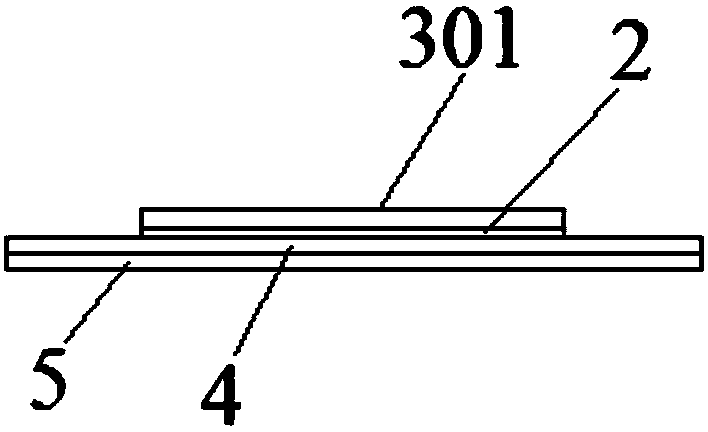

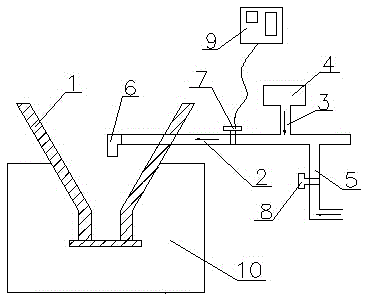

ActiveCN109531694AKeep the edges straightThe follow-up process is smoothMetal working apparatusTectorial membraneEngineering

The invention relates to a non-knife-mark die cutting method for a polyimide film product and a die cutting device. The non-knife-mark die cutting method specifically comprises the following steps that (1) a polyimide film material strip is attached to an auxiliary material strip, and then polyimide films are formed on the polyimide film material strip in a die cutting mode; (2) a second protecting film is attached to the polyimide film material strip, and then waste on the auxiliary material strip and the polyimide film material strip is discharged; and (3) a release film material strip is attached to the polyimide films and trimmed, and then waste on the second protecting film and the release film material strip is discharged. The die cutting device comprises an auxiliary material stripfeeding unit, a first die cutting unit, a second protecting film feeding unit, a first waste discharging unit, a release film material strip feeding unit, a second die cutting unit and a second wastedischarging unit. Compared with the prior art, no knife mark remains on the release film material strip of a final product, the integrity of the product on the material strip is good, and machining iseasy.

Owner:上海昊佰智造精密电子股份有限公司

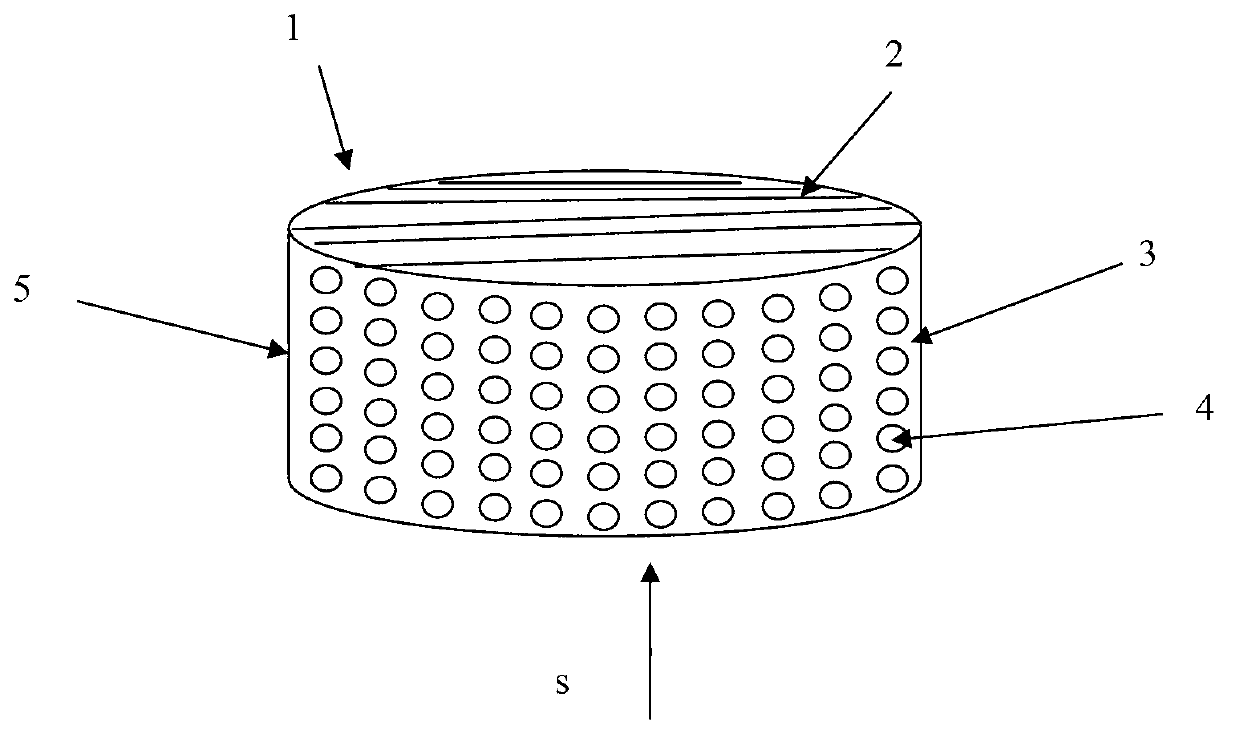

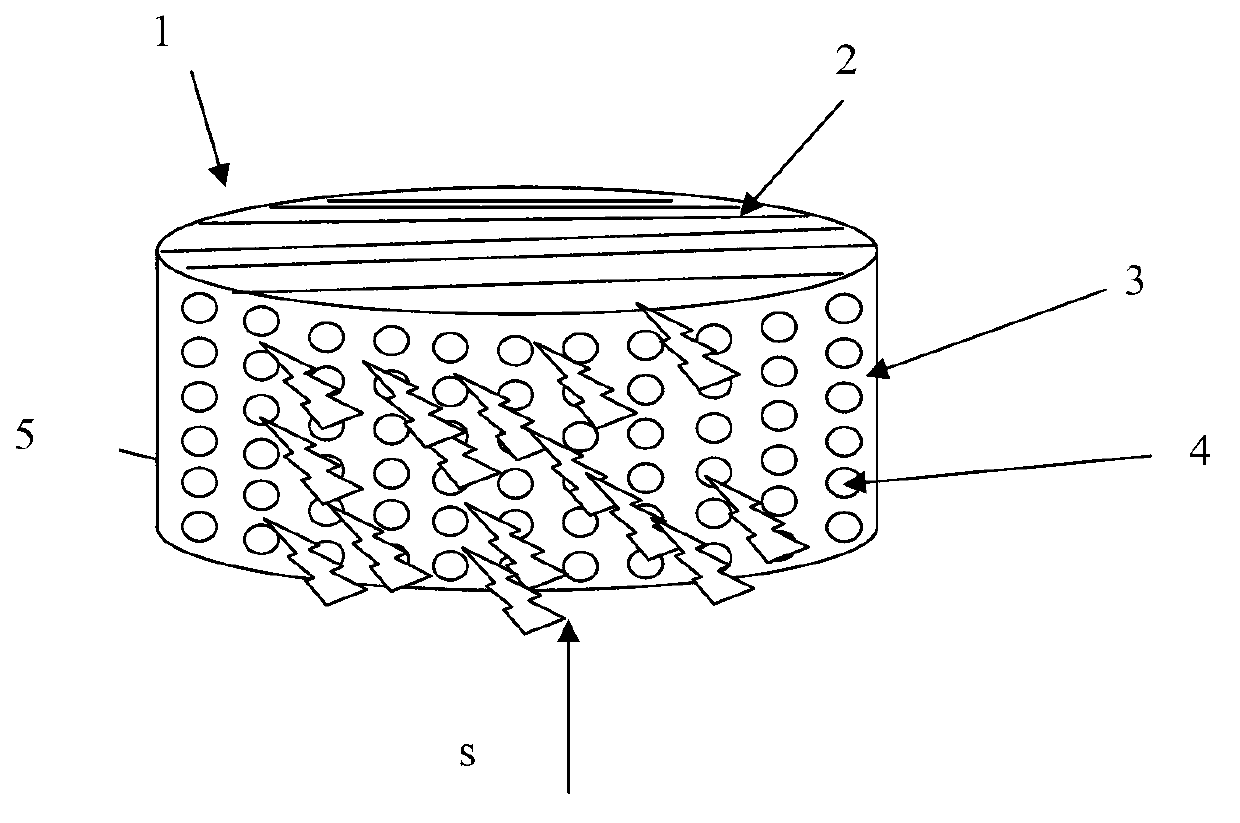

Quick-speed manufacturing method of complicated ceramic

InactiveCN101391896AReduce internal stressAvoid distortionCeramic shaping apparatusVolumetric Mass DensityNear net shape

The invention discloses a rapid manufacturing technology of complex ceramic parts, comprising the following steps: firstly, the initial billet of the ceramic parts is manufactured by utilizing the LOM technology and taking a ceramic film as the raw material; the initial billet of the ceramic parts is covered with a sheath and treated with pressure treatment after being put into an isostatic cool pressing furnace; the pressed billet of the ceramic parts is treated with degreasing treatment and high temperature sintering; and finally, a small quantity of subsequent processing is carried out to the parts near net-shape forming according to the precision requirements of the geometric dimension and shape of the parts. The essence of the invention is that isostatic cool pressing and LOM rapid shaping technologies are organically combined, the initial billet of the ceramic parts after LOM rapid shaping is treated with the isostatic cool pressing, thus improving the density of the billet and being beneficial to the subsequent sintering and densification processes. The invention combines the advantages of the LOM technology and the isostatic cool pressing technology, avoids complex mould design or sheath design, improves the performance of the final ceramic parts and is suitable for the manufacturing and small scale production of the ceramic parts with complex shape and structure.

Owner:HUAZHONG UNIV OF SCI & TECH

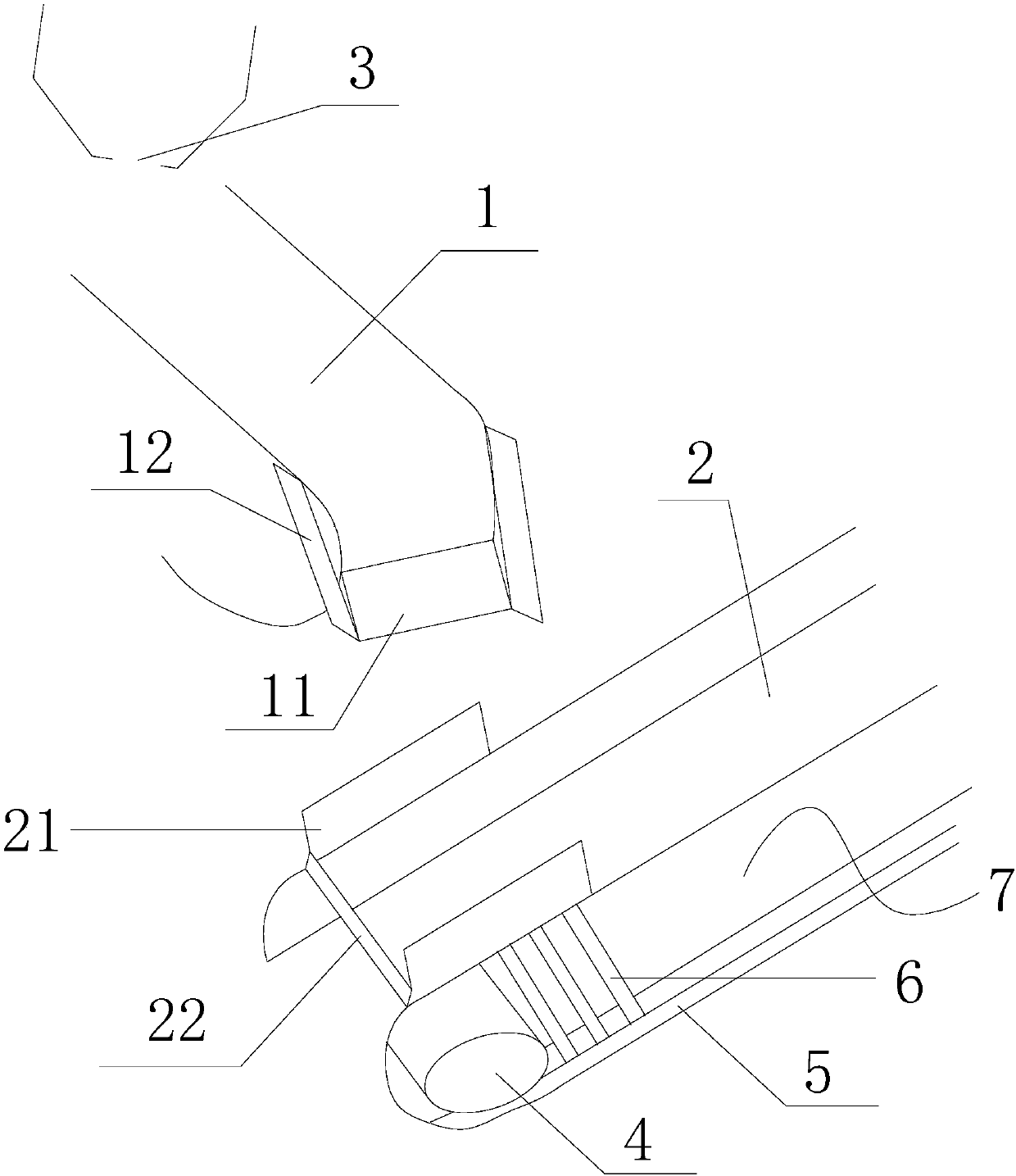

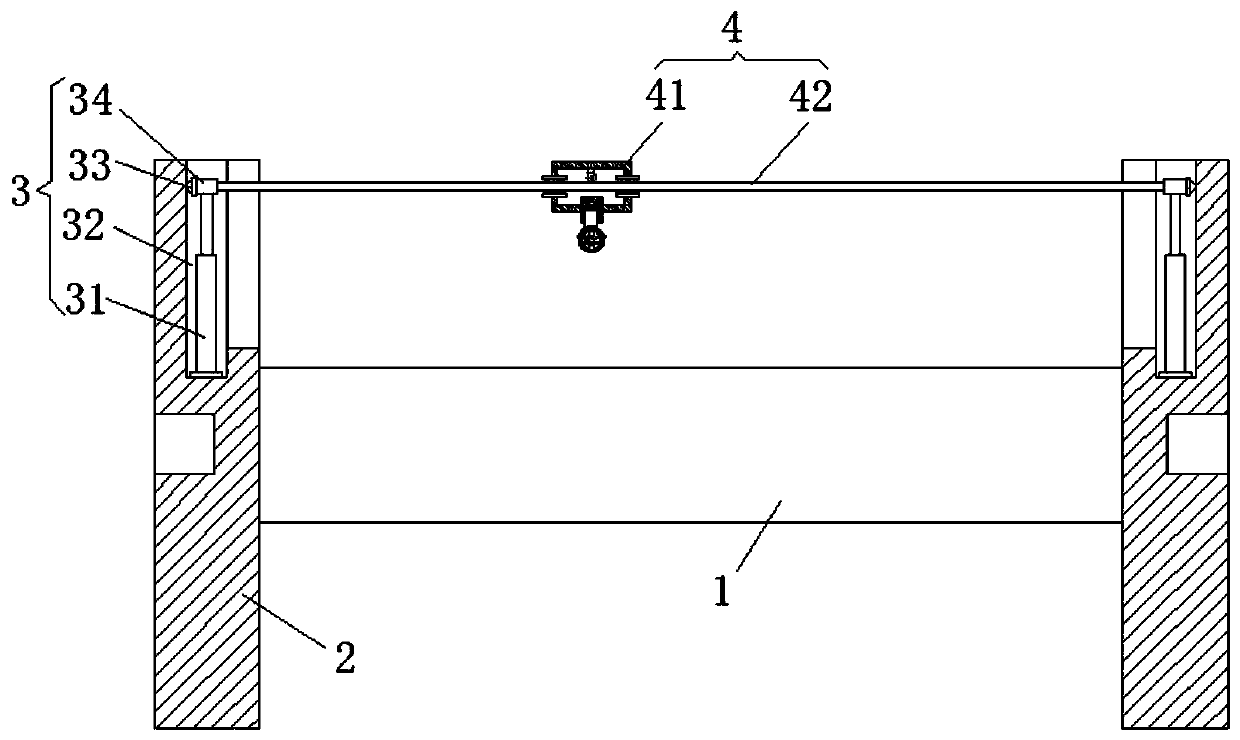

Improved spinning spool

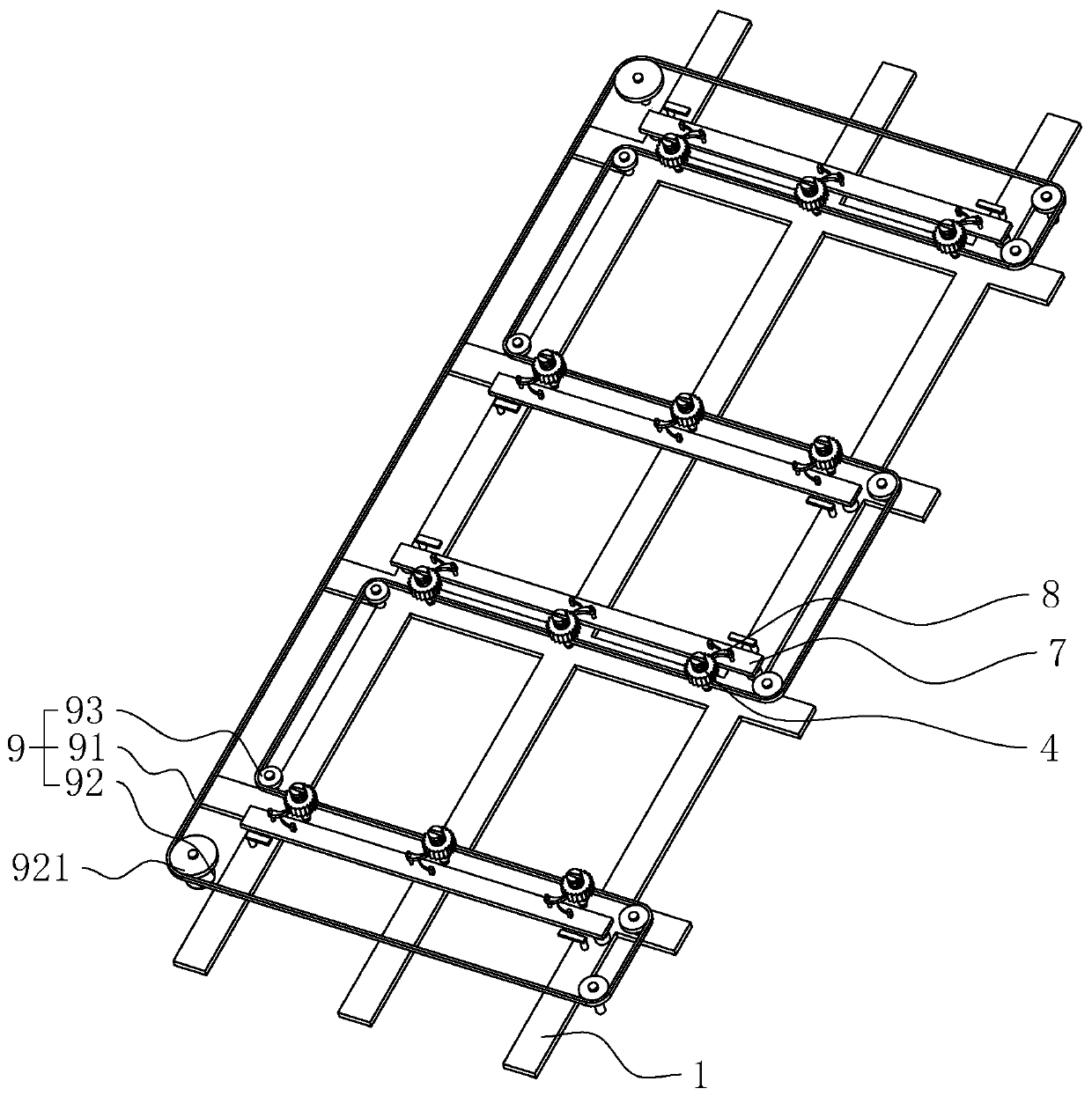

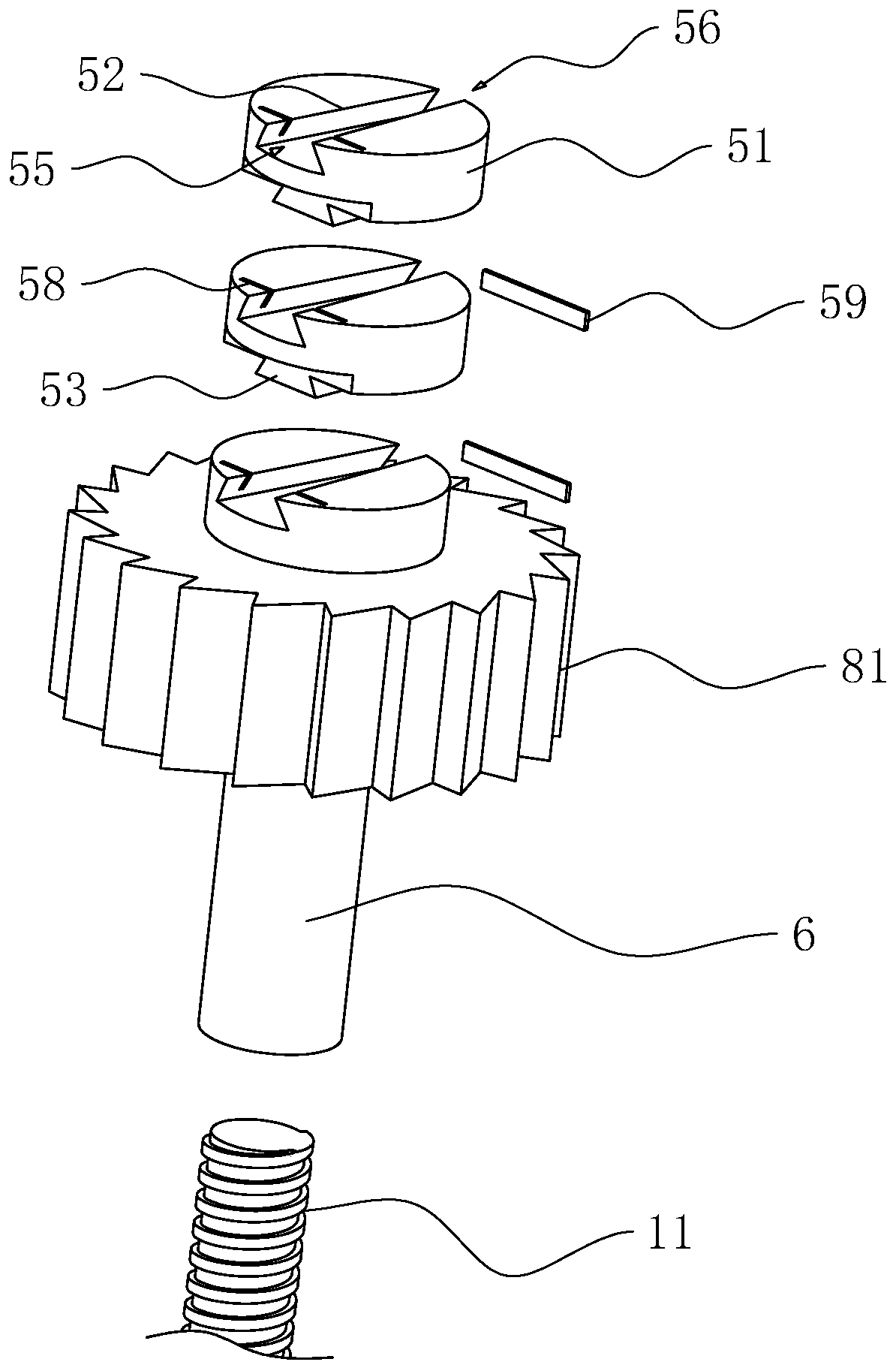

The invention relates to an improved spinning spool which comprises a winding shaft and side plates. The side plates are arranged at the ends of the winding shaft, the winding shaft is used for winding yarn, the two ends of the side plates are arranged on a spinner through installing grooves, lifting mechanisms are arranged at the top ends of the side plates, and a movable mechanism is arranged between the lifting mechanisms; the winding shaft is used for winding yarn, the side plates block the yarn from the two sides, the yarn is prevented from being scattered, the lifting mechanisms can drive the movable mechanism to move up and down, meanwhile, the movable mechanism is movable so as to adapt to yarn outlet operation of yarn at different positions, the movable mechanism comprises a movable branch chain and a guiding rod, the guiding rod is horizontally arranged between the lifting mechanisms, and the guiding rod is used for guiding the movable branch chain to move horizontally. Stability maintenance processing can be performed on the yarn, yarn swing repeating is reduced, and the yarn is prevented from being pulled apart; the dryness close to the spinning spool is lowered, the phenomenon that static electricity is generated in the yarn outlet process is avoided, and it is ensured that the follow-up procedures of the yarn can be performed successfully.

Owner:杭州余杭宏强丝绸有限公司

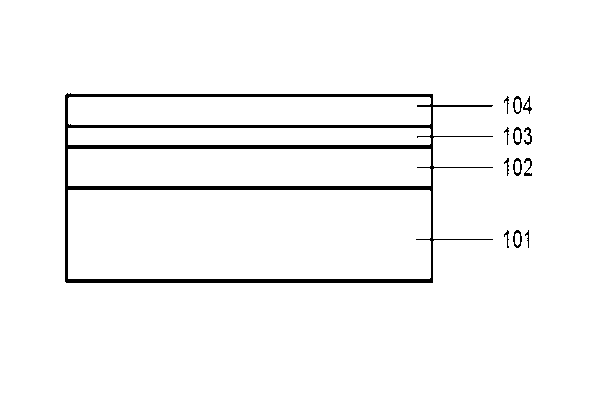

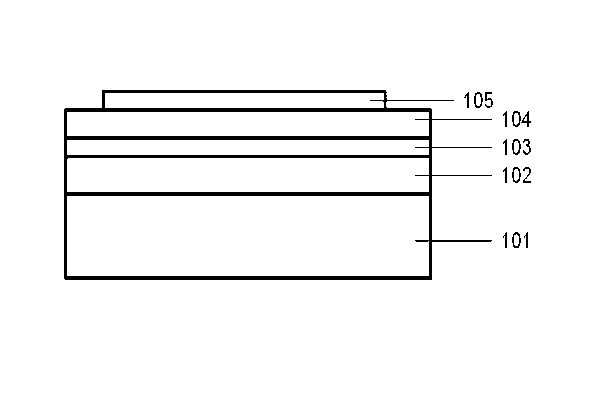

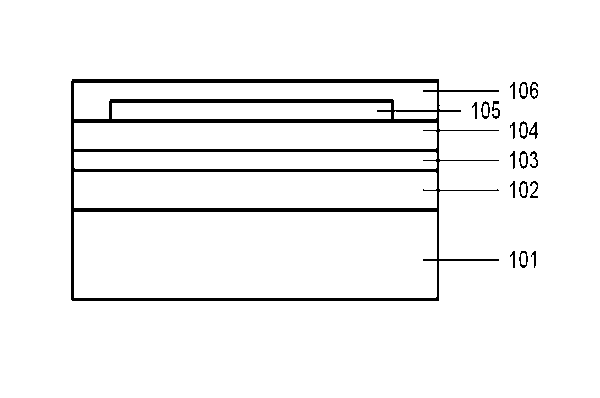

High-thermal conductive metal base plate used for transferring gallium nitride epitaxial layer of LED and preparation method thereof

InactiveCN101728476AAvoid chippingThe follow-up process is smoothSemiconductor devicesCopperGallium nitride

The invention discloses a high-thermal conductive metal base plate used for transferring a gallium nitride epitaxial layer of an LED and a preparation method thereof. The method comprises the following steps: performing conductive treatment on a substrate with a gallium nitride film layer; plating a metal A on the surface of the substrate with the gallium nitride film layer; plating a metal B on the surface of the metal A plating layer; alternately plating the metals A and B repeatedly to form a multilayer metal structure; thickening the surface of the multilayer metal structure by electroplating copper; plating a metal C on the surface of the copper; and finally, obtaining the high-thermal conductive metal base plate used for transferring the gallium nitride epitaxial layer of the LED. All the raw materials adopted by the invention do not contain heavy metals, so the raw materials are environment-friendly, the raw materials are simple and easily obtained, and the production process is easy to operate; and a metal base plate LED luminous device prepared by the method of the invention after transferring is applicable to the field of high-power LEDs. The prepared LED has the advantages of high luminous efficiency, low energy consumption, long service life and lower production cost, and accords with the condition of large-scale industrial application; and the quality of the LED accords with European Union Standards and United States Standards.

Owner:SUN YAT SEN UNIV

Fabric as combustor covering, and its making method

ActiveCN103132346AOptimizing IR PerformanceOptimized resistance to temperingAdhesivesYarnYarnEngineering

The invention provides a fabric as a combustor covering, and its making method. The fabric has a fluffy and dispersed metal fiber mesh structure and is obtained through weaving single or multiple filament metal fiber composite yarns containing an isolation material, and removing the isolation material. The fluffy characteristic of the fabric can be obtained only through the method. The fabric has the advantages possessed by a plurality of metal yarn fabrics obtained through twisting metal filaments (or bundled drawing metal fibers), has the characteristics of stable ventilation value, stable service life, and reservation of partial advantages of the cut metal fiber fabrics, and solves the key product application range restricting defects comprising bad infrared effect, easy tempering of infrared combustion of fabrics obtained through twisting the metal filaments (or the bundled drawing metal fibers) through original technologies.

Owner:HUNAN HUITONG ADVANCED MATERIALS

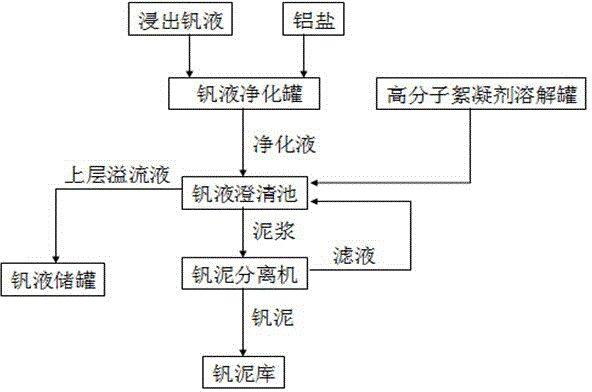

Settlement method of vanadium mud in leached vanadium liquid

ActiveCN104129838ASettling fastImprove purification efficiencyProcess efficiency improvementWater/sewage treatment by flocculation/precipitationAluminium sulfateSilicon

The invention discloses a settlement method of vanadium mud in a leached vanadium liquid. The settlement method comprises the following steps of adding an aluminum salt into a leached vanadium liquid for purification, adding a polymer flocculant solution into the purified vanadium liquid, carrying out mixing to obtain a uniform mixture, and carrying out standing for solid-liquid separation so that a clear vanadium liquid and vanadium mud are obtained. The leached liquid is added with the aluminum salt for purification and then is added with the polymer flocculant solution so that the vanadium mud can be fast deposited. Therefore, the settlement method effectively improves a vanadium mud sedimentation rate, shortens vanadium sedimentation time and effectively improves vanadium liquid purification efficiency so that the whole production process connection is more smooth, vanadium sedimentation time of the vanadium sedimentation process is shortened to about 100min from 250min and production efficiency is improved. The settlement method effectively reduces silicon and phosphor impurity content of the vanadium liquid, reduces a vanadium concentration of the supernatant, effectively reduces unit consumption of aluminum sulfate as a purification agent, reduces system vanadium loss, improves vanadium mud separation efficiency, reduces transport amount of a turbid vanadium liquid and reduces energy consumption.

Owner:HEBEI IRON AND STEEL

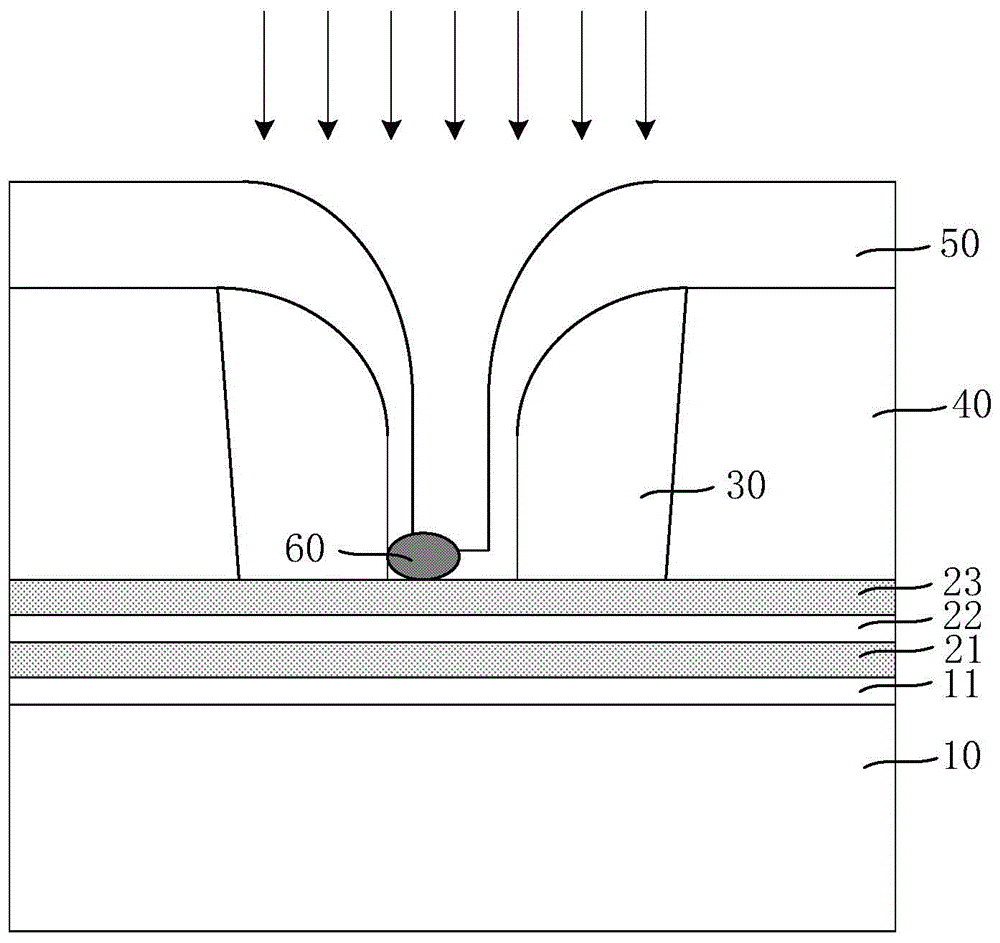

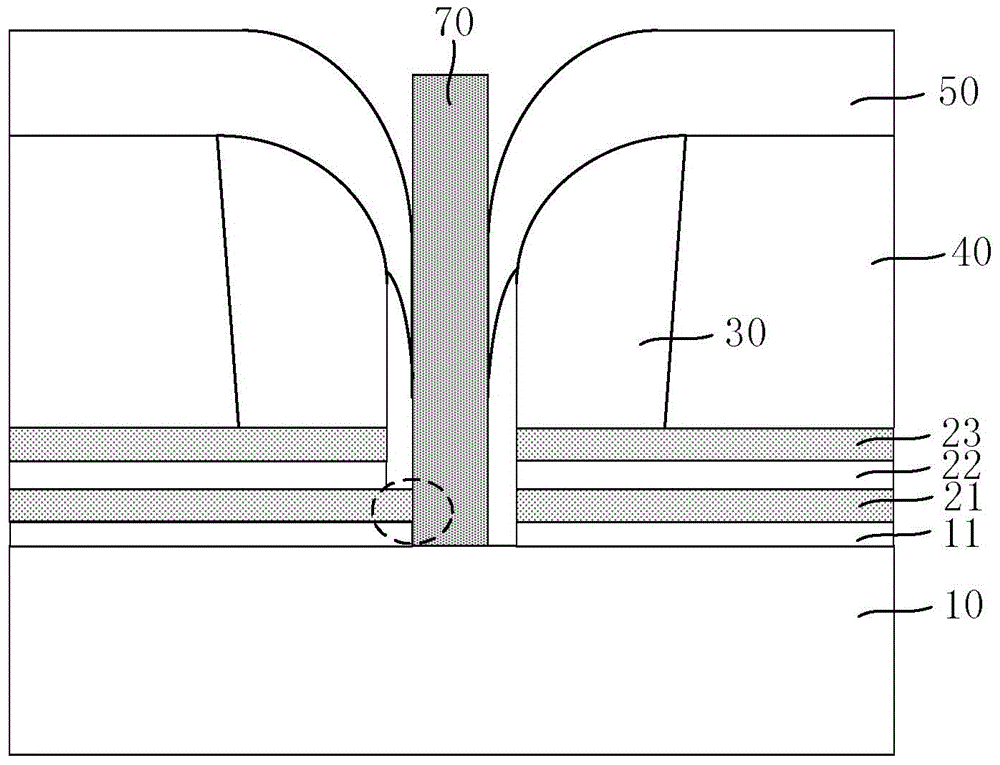

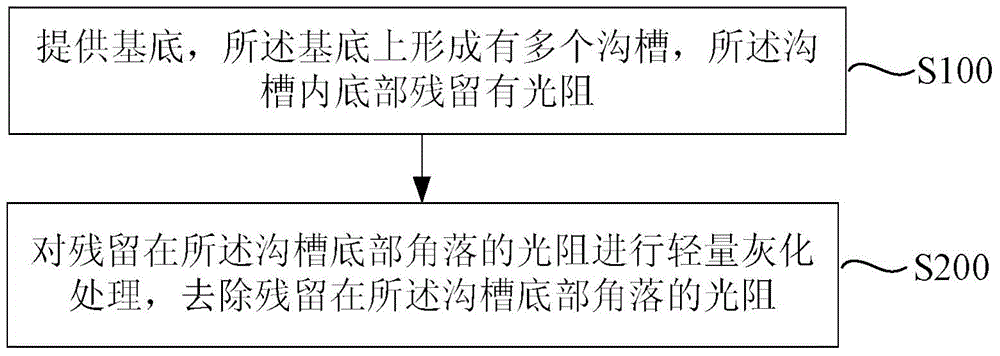

Method to remove photoresist from deep groove and manufacturing method of flash memory

ActiveCN105470127AThe follow-up process is smoothAvoid short circuitSemiconductor/solid-state device manufacturingPulp and paper industryPhotoresist

The invention provides a method to remove photoresist from a deep groove and a manufacturing method of a flash memory. Photoresist in the bottom corners of the grooves is ashed into gas by utilizing a light ashing technology, so that the residual photoresist in the bottom corners of the deep groove is removed, and subsequent process can be implemented smoothly. Further, when the flash memory is formed, the residual photoresist at the bottom corners of the deep groove is removed in the light ashing technology, so that subsequent etching process can be carried out smoothly, a floating gate and a source wire formed subsequently are prevented from short circuit, and the yield rate of the flash memory is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

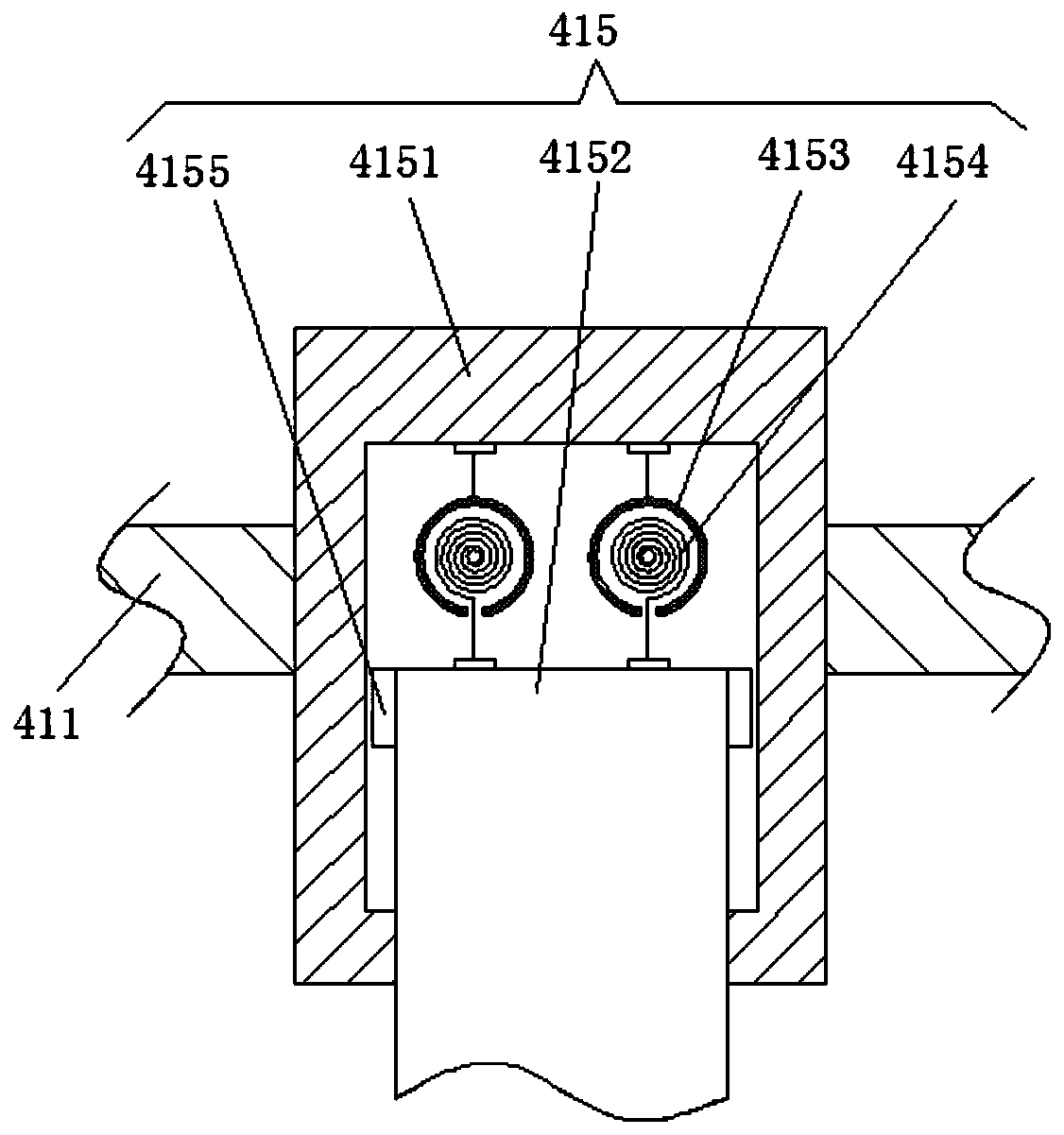

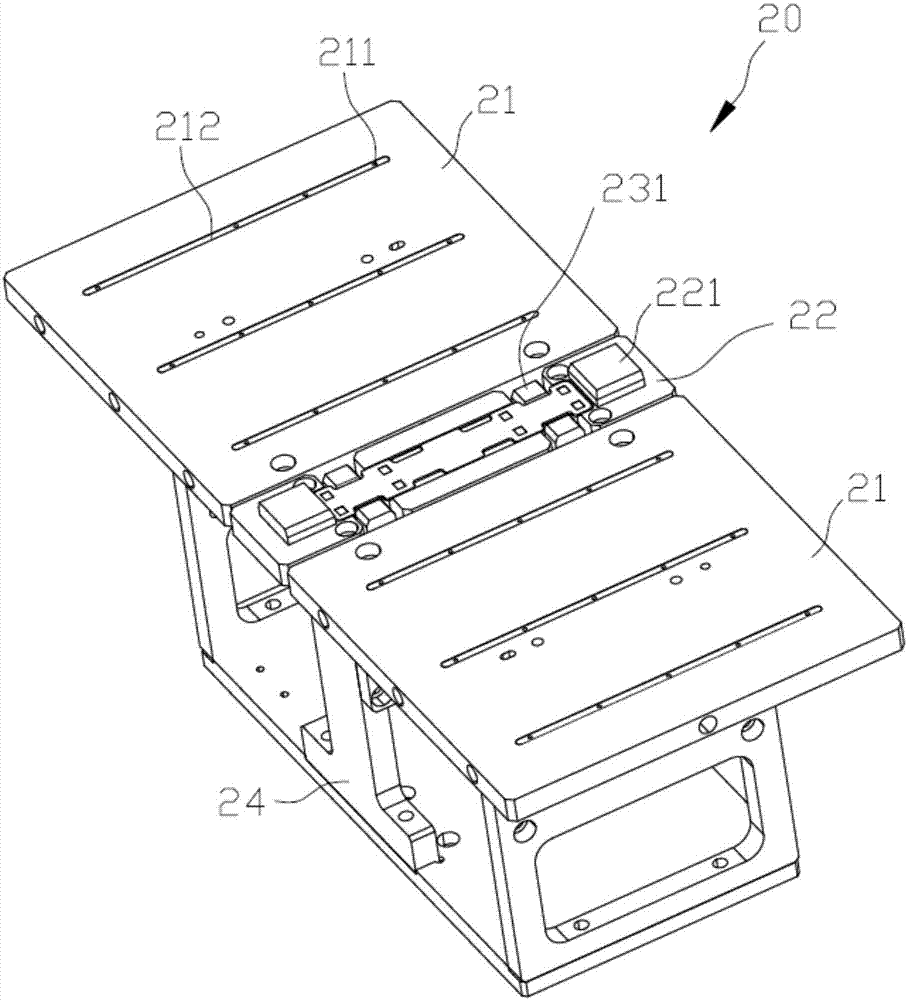

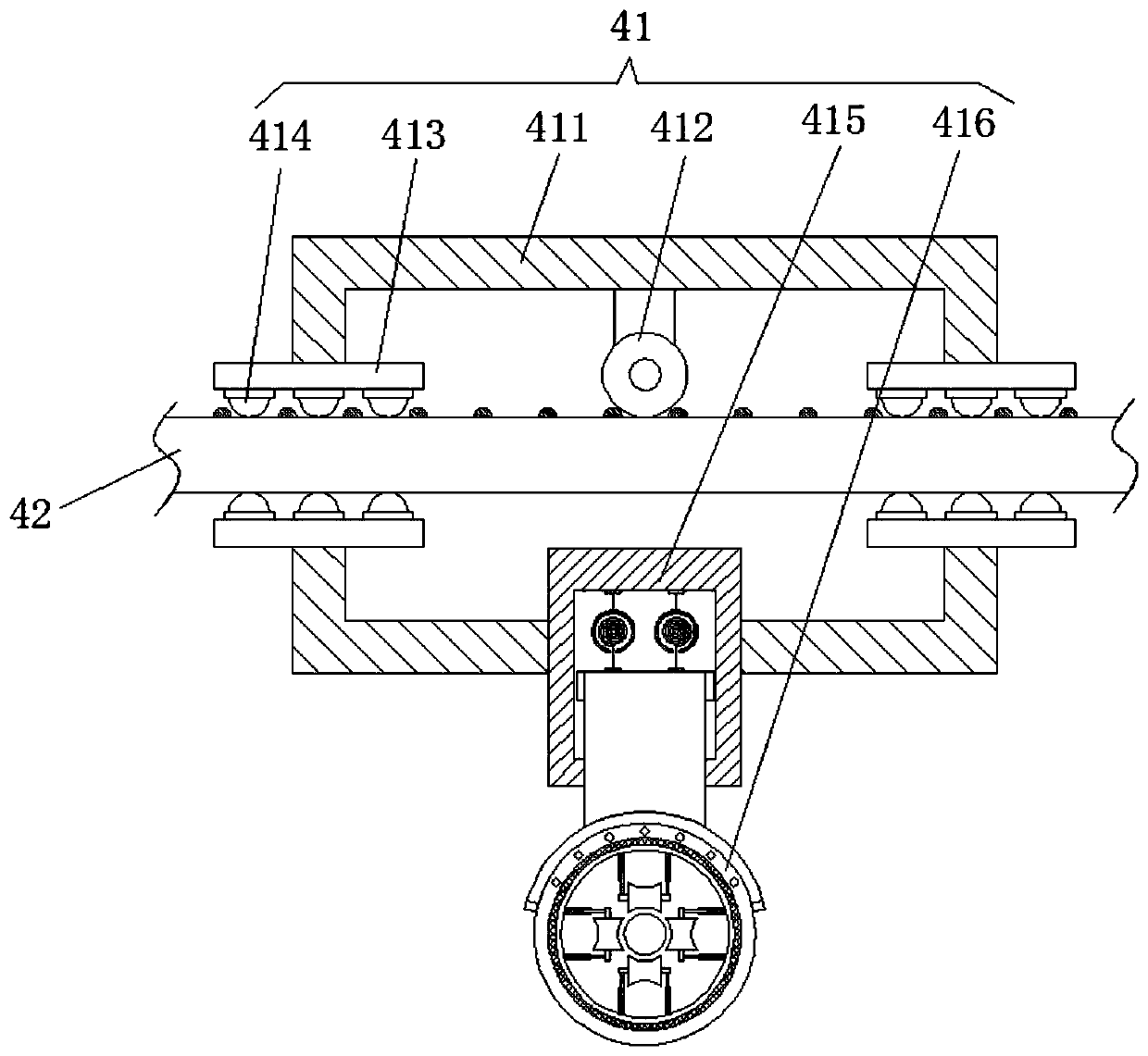

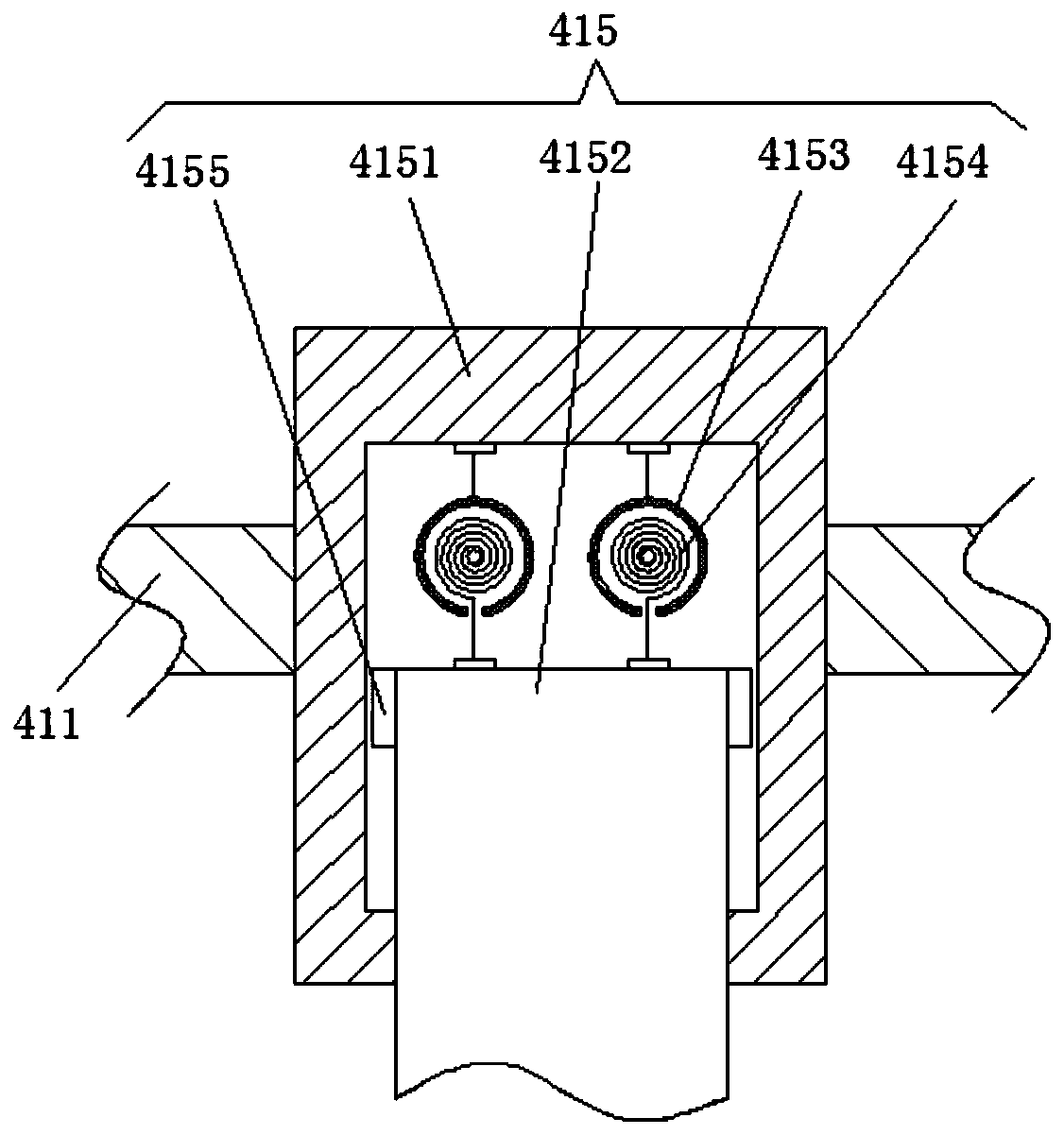

Film sucking and heating mechanism, and insulating feeding, heating and transferring mechanism

PendingCN107275665ASimplify the flow processAvoid breakingAssembling battery machinesFinal product manufactureTransfer mechanismElectrical and Electronics engineering

Owner:海目星激光科技集团股份有限公司

Production process of guide board

The invention relates to a production process of a guide board. The production process comprises the following steps that S01, cutting is performed, particularly, an aluminum alloy plate is selected and cut according to the design size, and a bottom plate is obtained; S02, cleaning is performed, and particularly the bottom plate is cleaned; S03, surface treatment is carried out, and particularly,the bottom plate treated in the step S02 is soaked in an alkaline cleaning agent to be cleaned, then is washed with clear water, and is dried by hot air blowing or infrared rays; S04, a reflective film is pasted, and particularly the reflective film is pasted to the surface of the bottom plate treated in the step S03; S05, character engraving is carried out, particularly, patterns and characters are arranged through a computer, and characters and patterns are directly engraved on the reflective film through a computer engraving machine; and S06, pressing is carried out, and particularly the characters and patterns on the reflective film are scraped and pressed through a rubber plate. The production process has the advantages that the manufacturing process is simple and reasonable, and theobtained guide board is good in quality.

Owner:浙江众汇交通科技有限公司

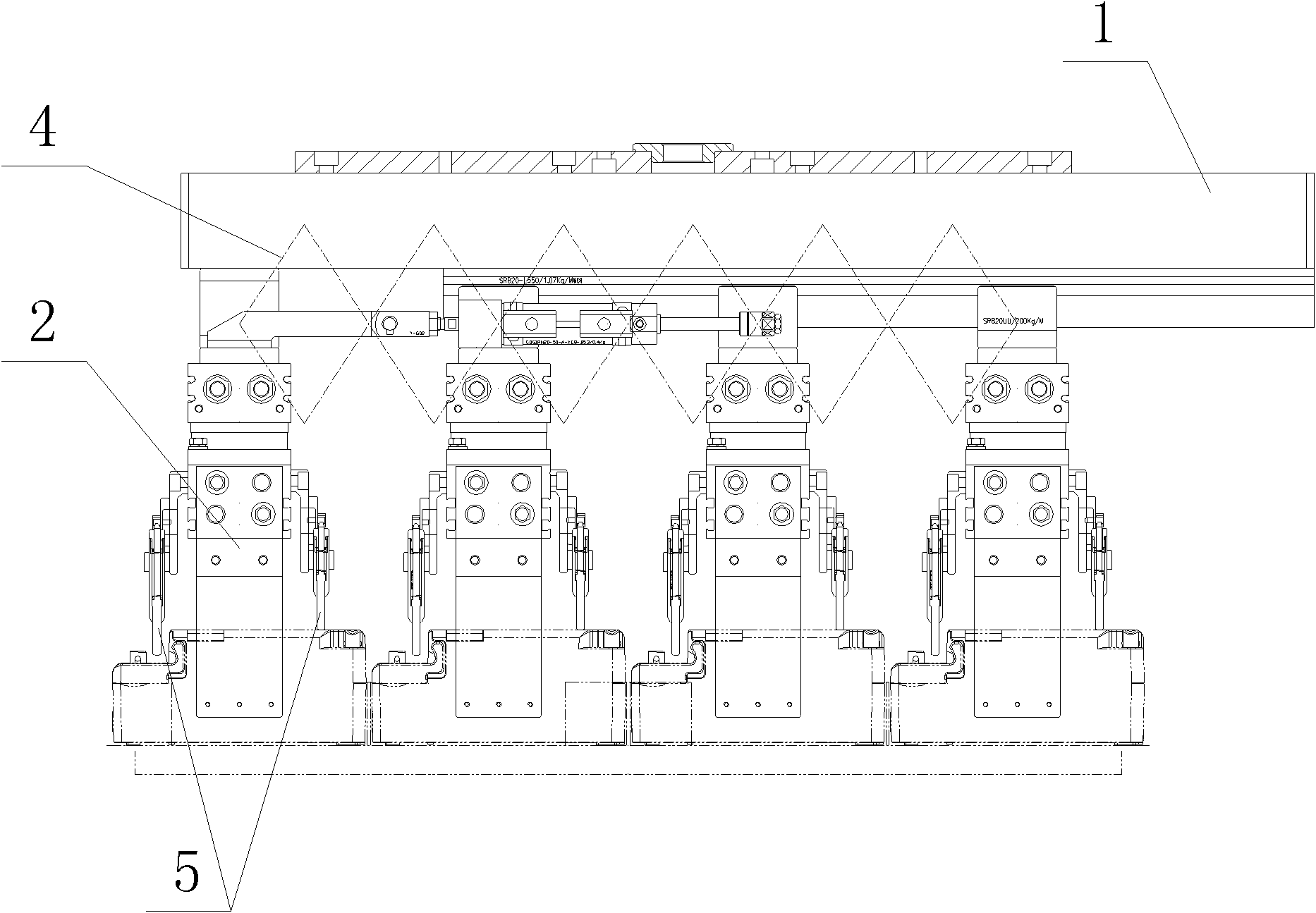

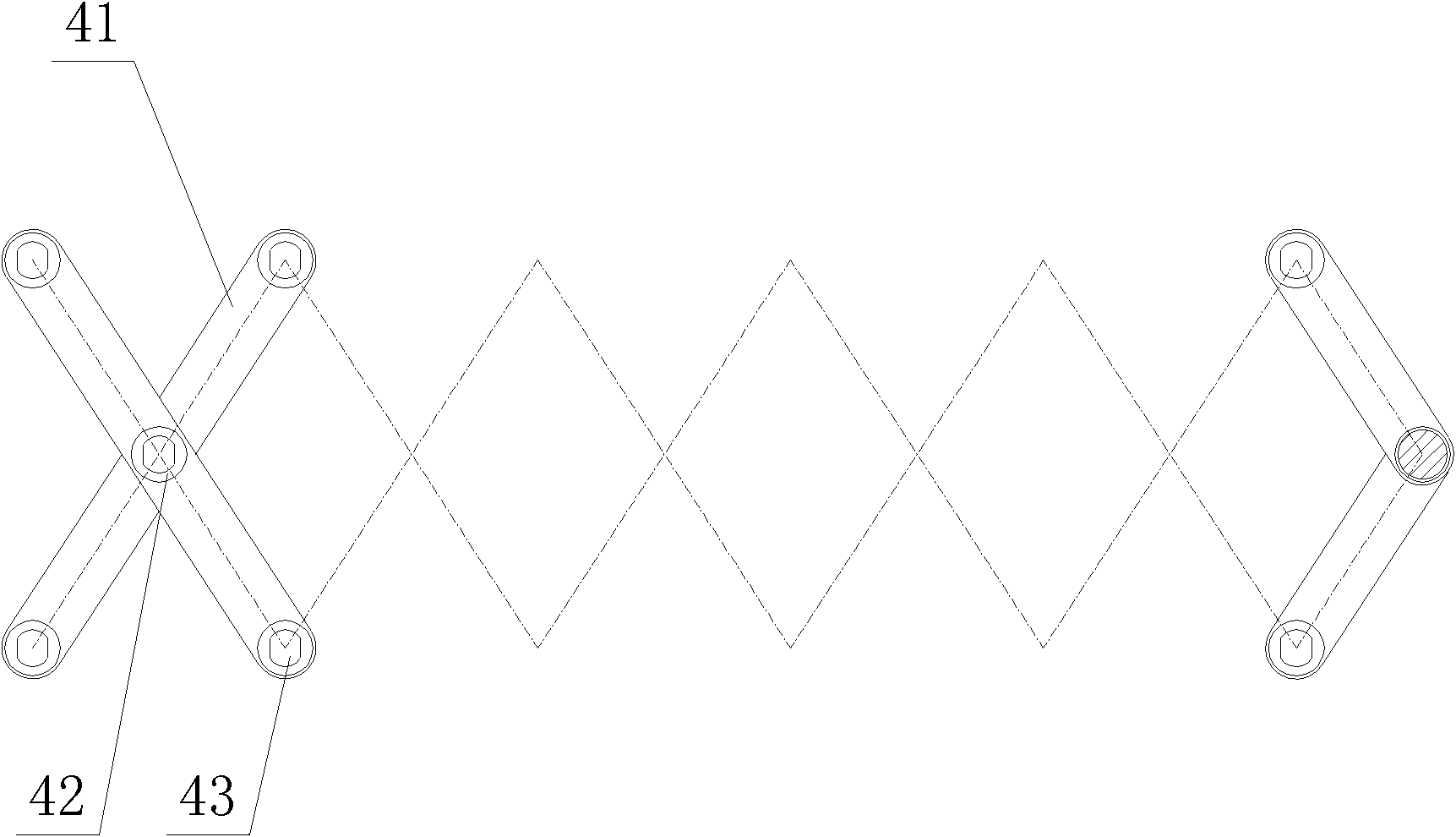

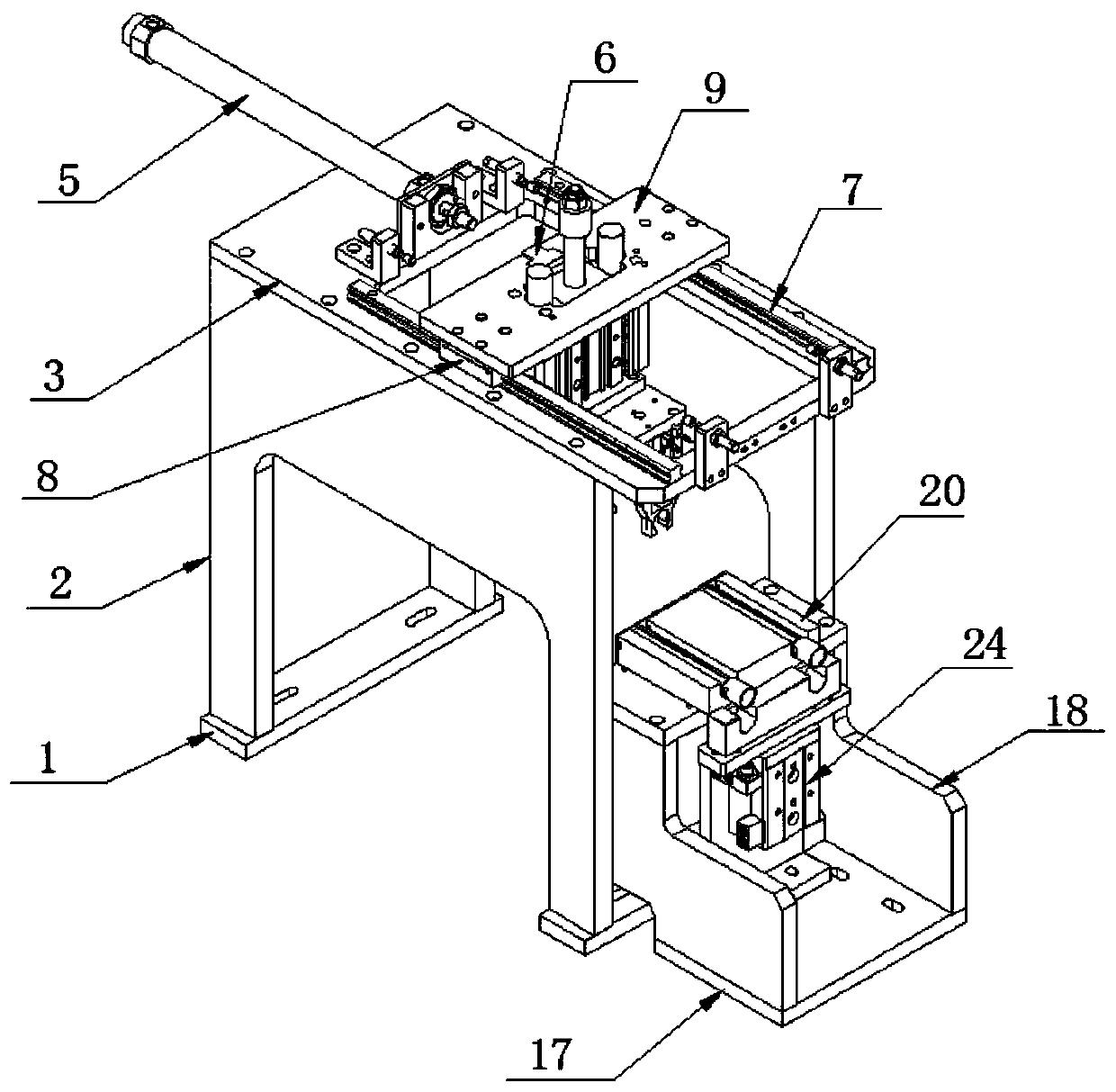

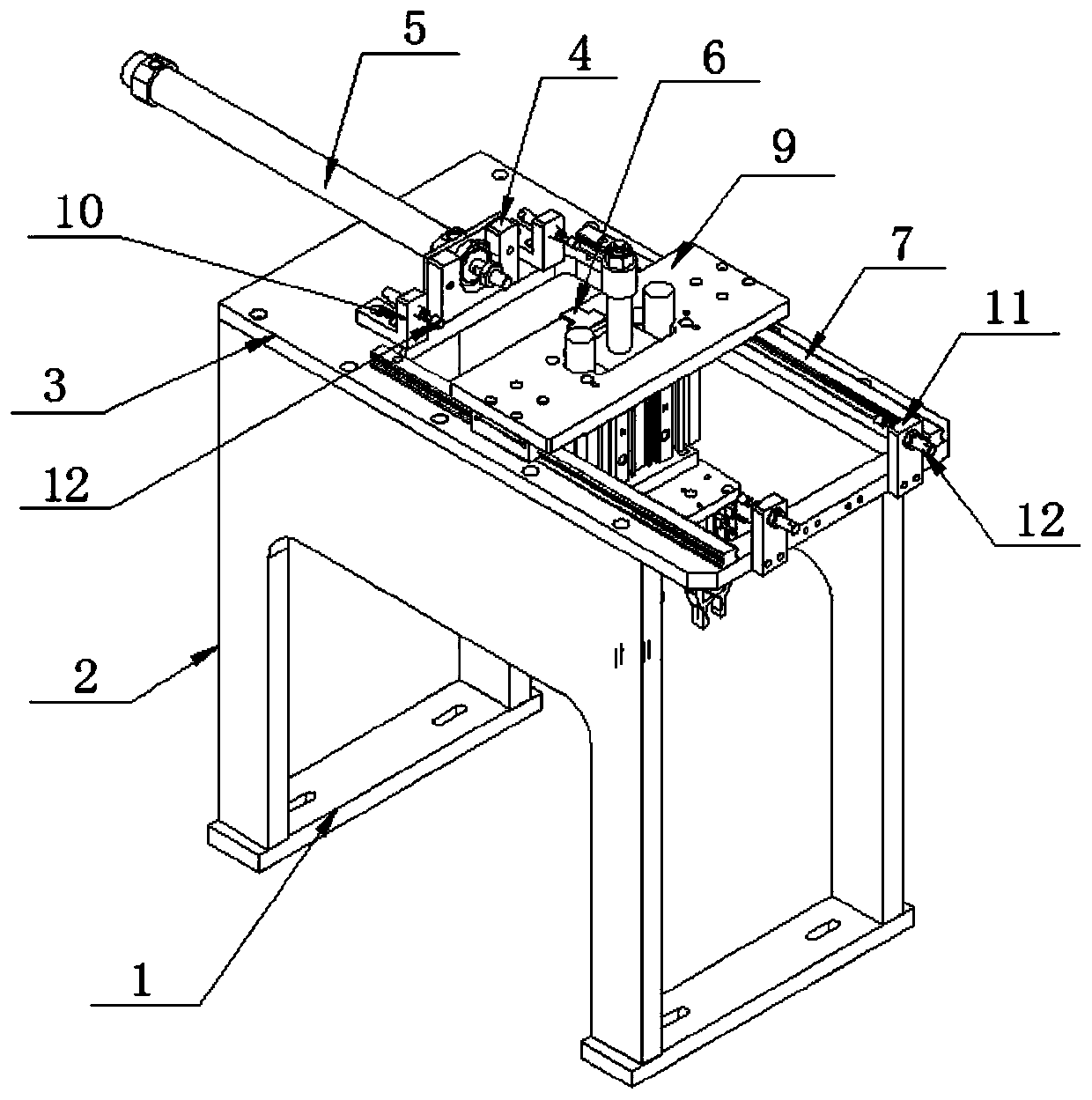

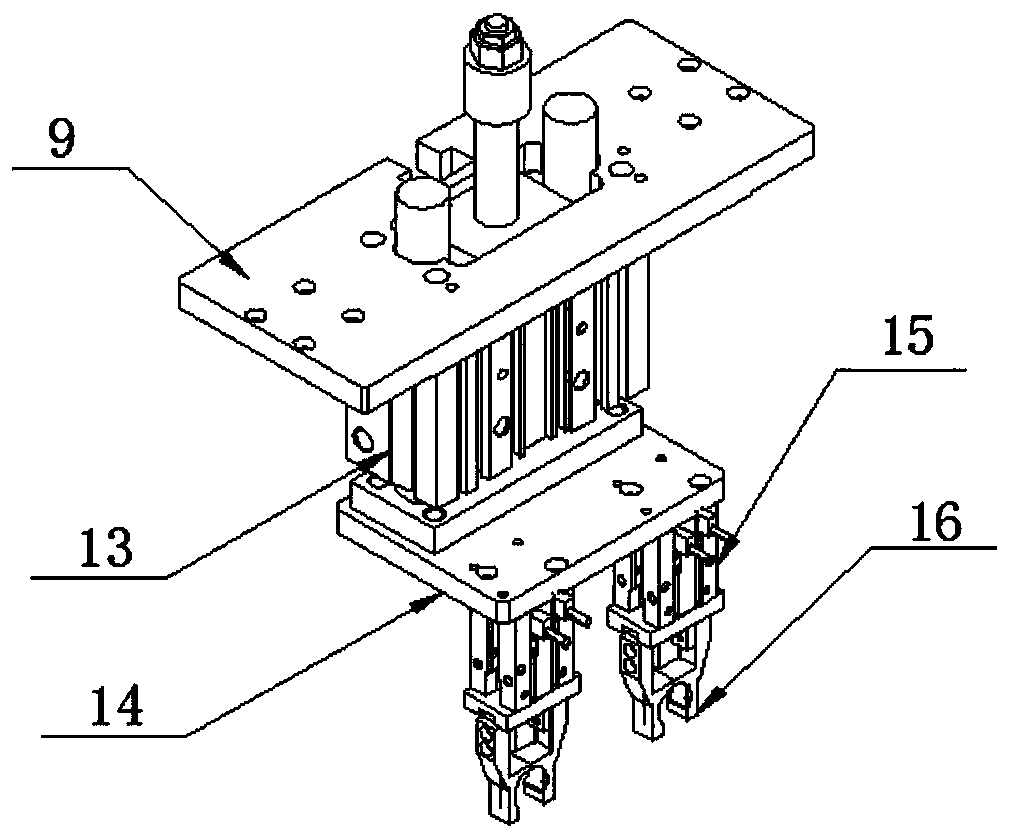

Loading and unloading mechanical hand for kilowatt-hour meter

InactiveCN102092047AReduce the difficulty of distance precision controlRealize fixed distance telescopicProgramme-controlled manipulatorHydraulic cylinderEngineering

The invention discloses a loading and unloading mechanism hand for a kilowatt-hour meter, which comprises a frame and at least three groups of mechanical hands, wherein the mechanical hands are arranged on the frame like a straight line, the mechanical hand at the leftmost end is fixed on the frame, other mechanical hands are arranged on the frame in a sliding manner, the mechanical hand at the leftmost end is connected with the adjacent mechanical hand through a hydraulic cylinder, and all the mechanical hands are connected onto a linkage folding device. The loading and unloading mechanism hand for the kilowatt-hour meter has the advantages that the linkage folding device is utilized, when the distance between the two mechanical hands is increased or reduced through the hydraulic cylinder, the distances between all the mechanical hands change synchronously in the same quantity, fixed-distance extension and contraction can be realized, the difficulty in precision control of the distances between the mechanical hands is reduced, and follow-up process steps can be performed more smoothly.

Owner:ZHEJIANG HOUDAR INTELIGENT TECH CO LTD

Waste heat recovery device and process for dusty flue gas

InactiveCN105222145AReduce the temperatureSimple structureLighting and heating apparatusCombustion technology mitigationWaste heat recovery unitFlue gas

The invention provides a waste heat recovery device and process for dusty flue gas. The waste heat recovery device comprises a shell, a heat pipe and a thermal insulation plate; the thermal insulation plate divides the shell into an upper portion and a lower portion which are an upper shell and a lower shell respectively; a heat exchange medium inlet and a heat exchange medium outlet are formed in the upper shell; the lower shell is conical and provided with a flue gas inlet and a flue gas outlet, and a flue dust outlet is formed in the bottom of the lower shell; the heat pipe is installed on the thermal insulation plate, one end of the heat pipe is located inside the upper shell, and the other end of the heat pipe is located inside the lower shell. By means of the waste heat recovery device for the dusty flue gas, the waste heat recovery efficiency for the dusty flue gas is high; device blockage is avoided in the waste heat recovery process; besides, the waste heat recovery device is simple in structure and intelligent, the waste heat recovery process for the dusty flue gas is short, flue gas temperature can be effectively reduced, and smooth operation of the subsequent processes of flue gas treatment can be guaranteed.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

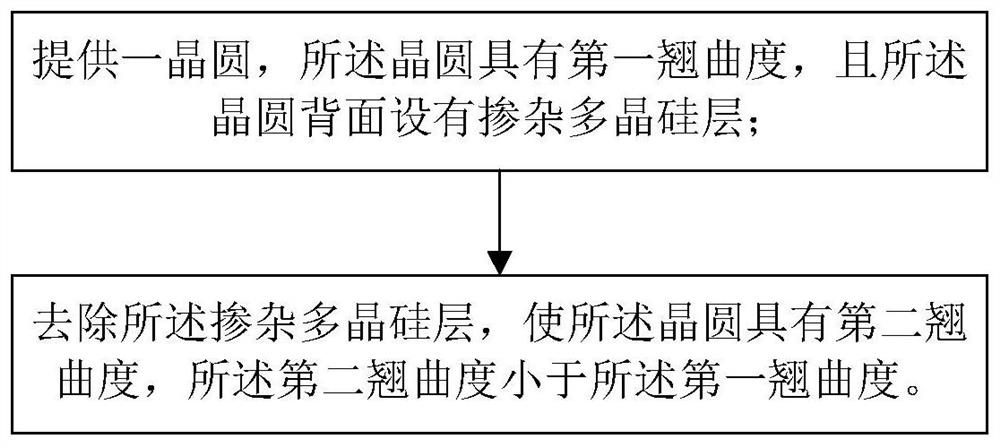

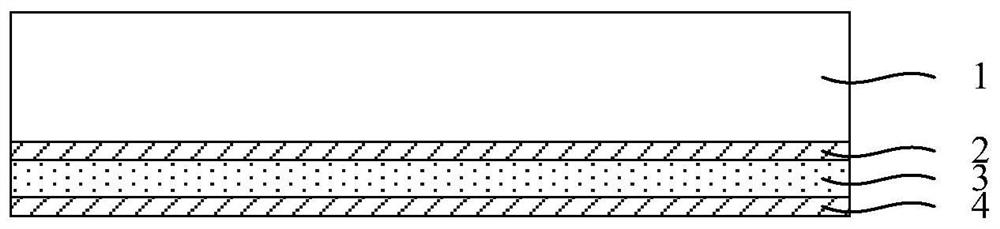

Semiconductor structure and manufacturing method thereof

ActiveCN113035688AImprove warpage variationAvoid adverse effectsSemiconductor/solid-state device manufacturingPhysicsPolycrystalline silicon

The invention provides a semiconductor structure and a manufacturing method thereof. The manufacturing method comprises the following steps that: a wafer is provided, the wafer comprises a front surface used for forming a semiconductor device and a back surface opposite to the front surface, a doped polycrystalline silicon layer is grown on the back surface of the wafer, and the wafer has a first warping degree; and the doped polycrystalline silicon layer is removed, so that the wafer has a second warping degree, and the second warping degree is smaller than the first warping degree. According to the semiconductor structure and manufacturing method thereof of the invention, the polycrystalline silicon film layer on the back surface of the wafer is reduced, so that the warping degree change in the stretching direction of the wafer can be improved; in addition, after the polycrystalline silicon film layer on the back face of the wafer is removed, the silicon dioxide layer is further formed on the back face of the wafer; under the condition that the total thickness of the wafer is not increased or even reduced, the warping degree change of the wafer in the stretching direction can be further improved, and adverse effects caused by increase of the thickness of the wafer are avoided. The wafer warping degree is improved, so that the subsequent process can be carried out smoothly, and the production yield can be improved.

Owner:CHINA RESOURCES MICROELECTRONICS (CHONGQING) CO LTD

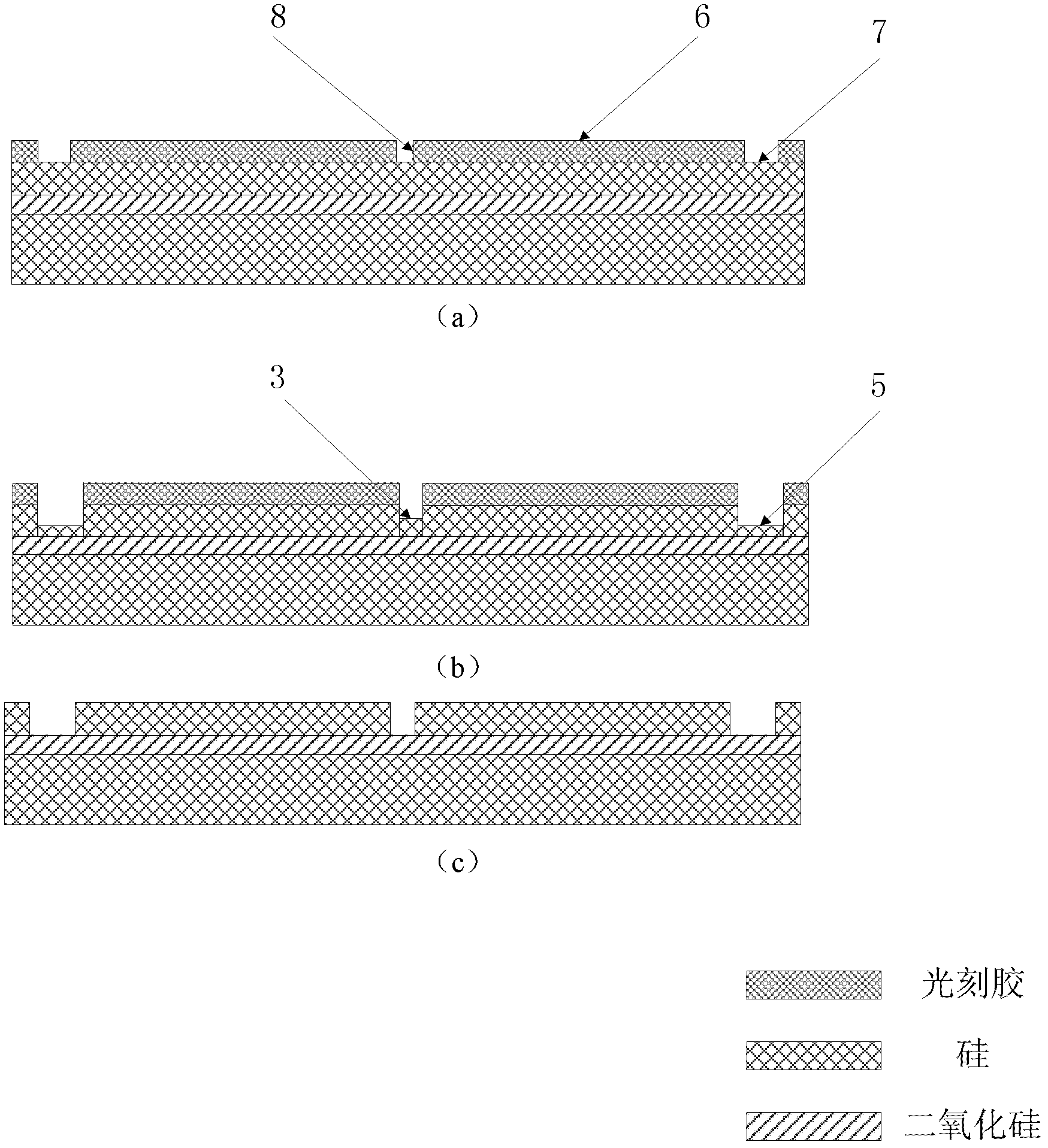

Manufacturing method for light emitting diode (LED) metal base board

InactiveCN102709405AImprove connection strengthEnough to support the hardnessSemiconductor devicesQuantum wellReflective layer

The invention discloses a manufacturing method for a light emitting diode (LED) metal base board, which relates to a substrate transition technology in the technical field of photoelectricity. The method comprises the following steps of: sequentially growing an N-typed GaN semi-conductive layer, a quantum well active layer and a P-typed GaN semi-conductive layer on a sapphire substrate; carrying out vapor depositing on a metal mirror reflective layer on the P-typed GaN semi-conductive layer; pre-plating multiple metal layers as a seed layer on a face of an appliance which needs a substrate transition through the electroplating; coating with photoresist on a channel; carrying out oxidization on the metal surface of the seed layer, and the metal base board is obtained through the method of electroplating; and cutting along the position of photoresist to obtain the required core particles. According to the manufacturing method, the combination strength of the metal base board and a GaN extension layer is high, and convenience in mechanical cutting can be easily realized, the manufacturing method has the advantages of simple process, low cost and easiness in obtaining raw materials.

Owner:TONGFANG OPTO ELECTRONICS

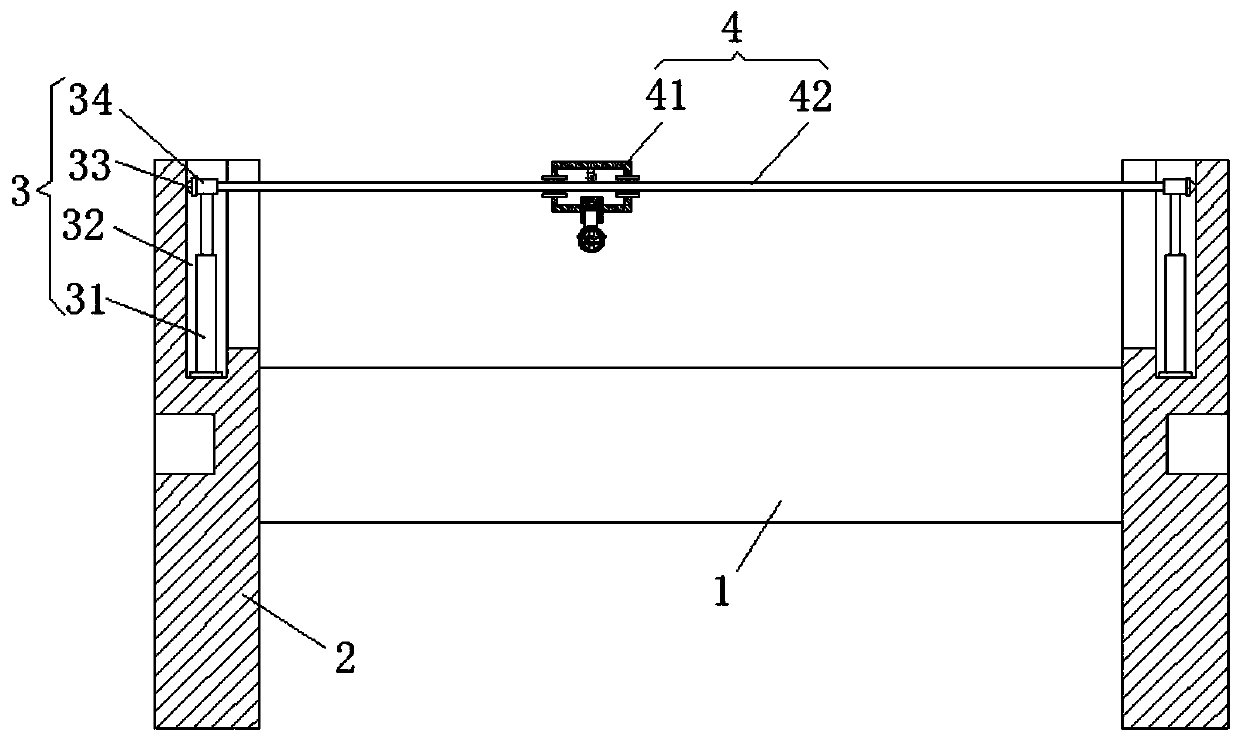

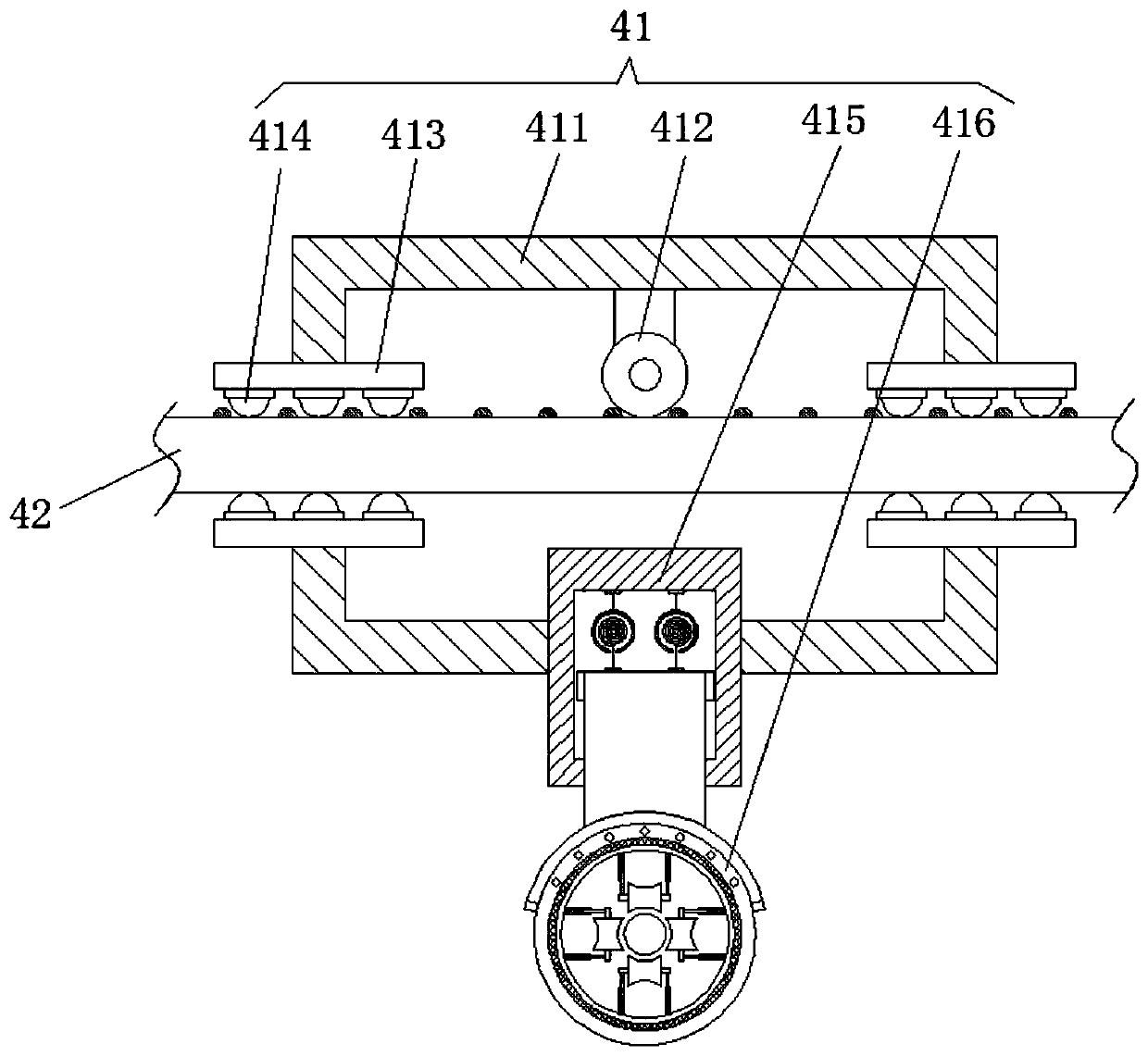

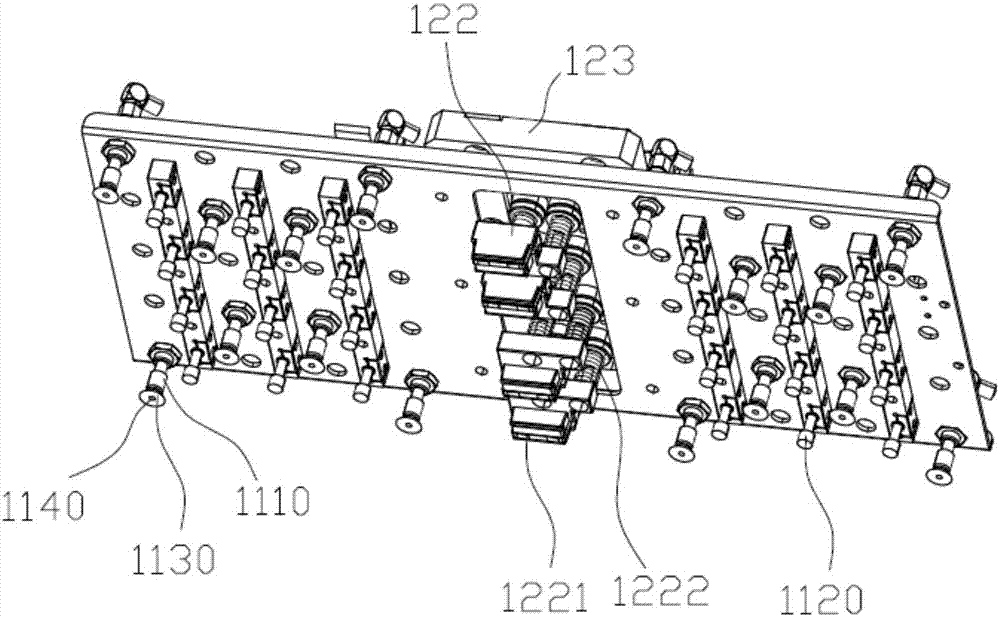

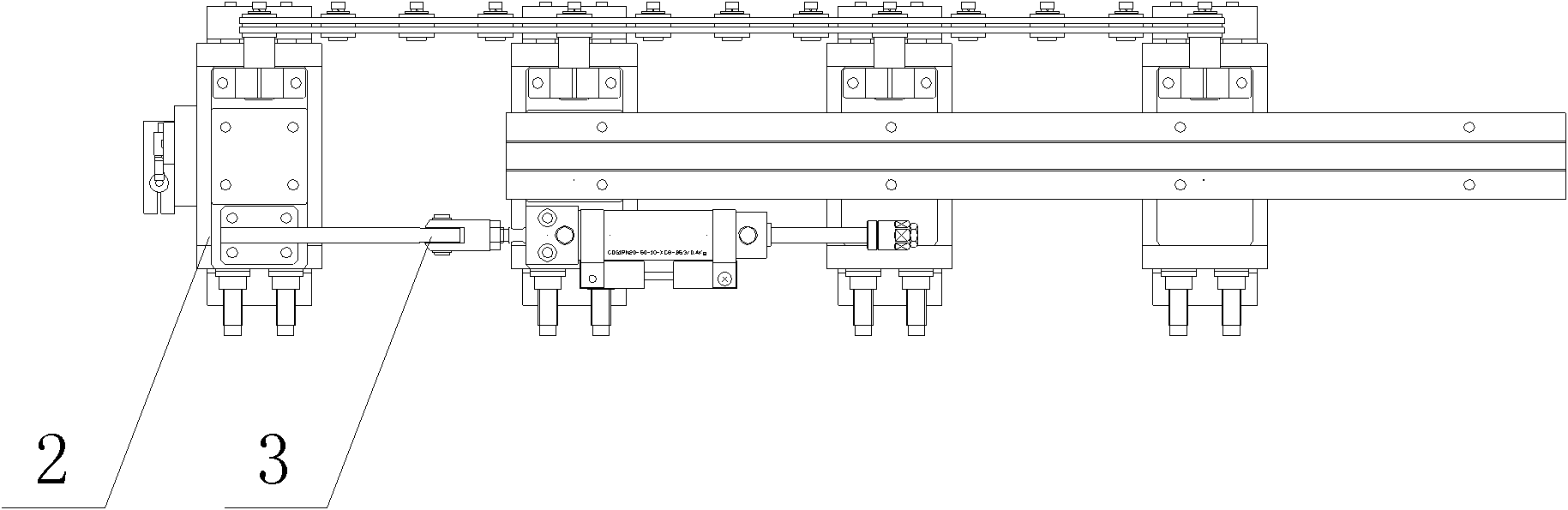

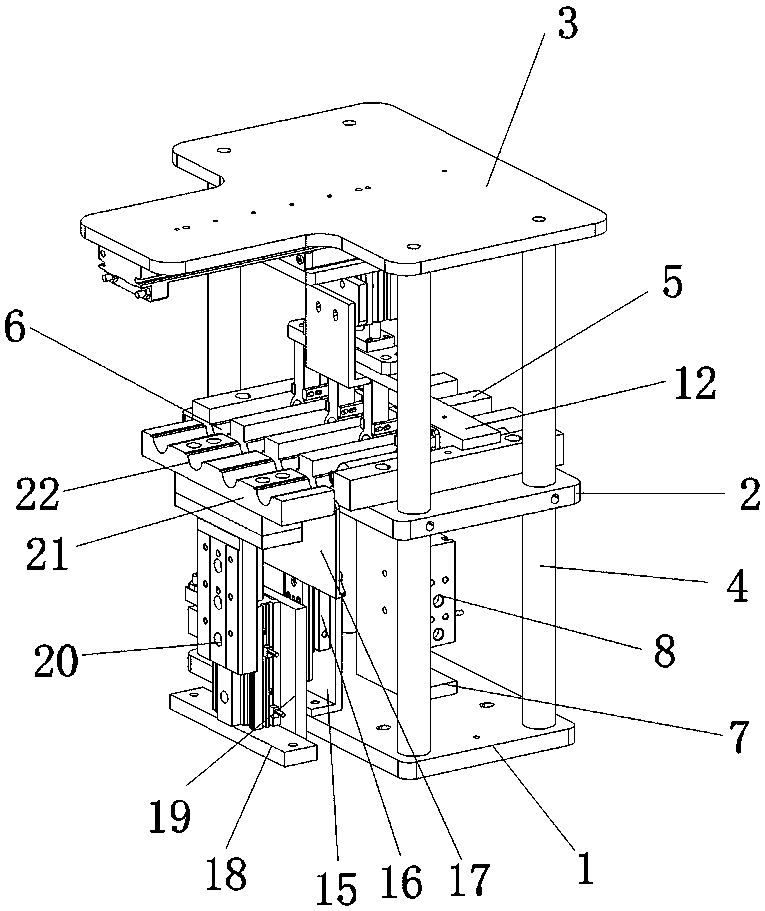

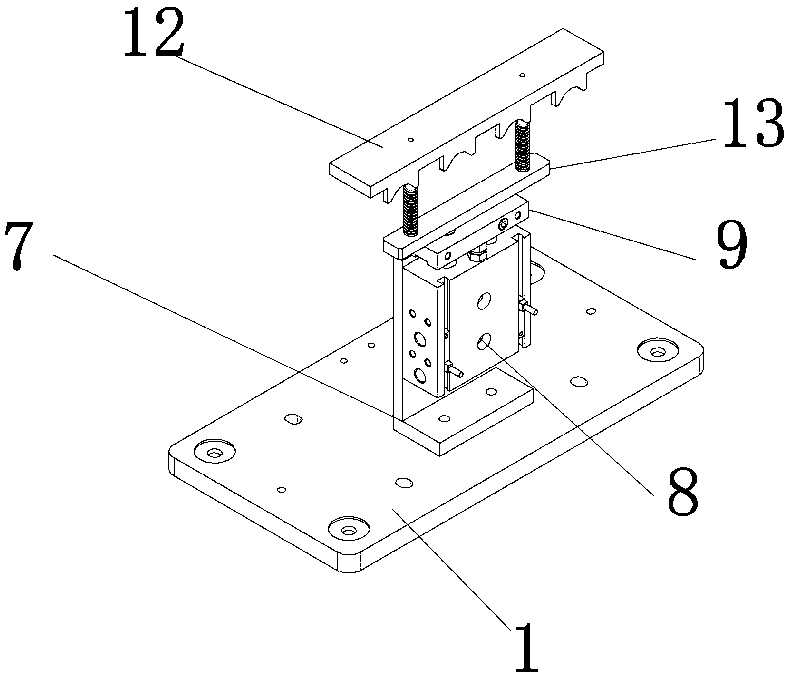

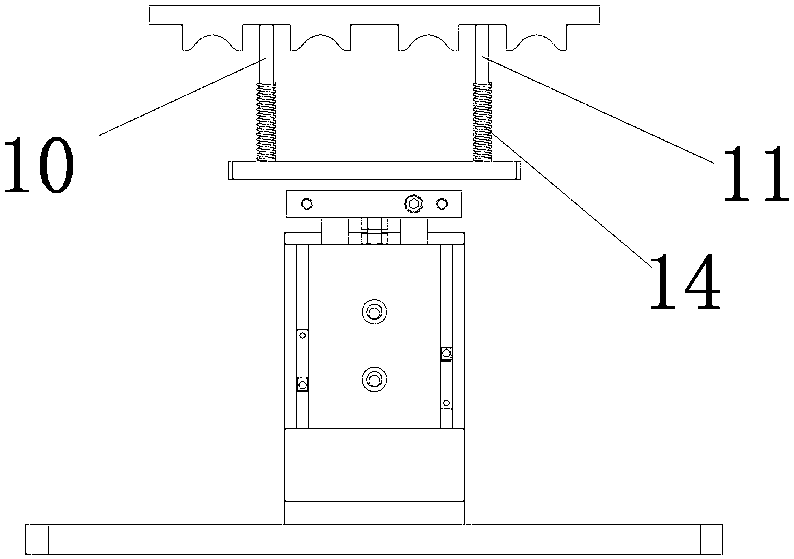

Blood transfusion apparatus dripping bucket bottle separation and supply device

The invention provides a blood transfusion apparatus dripping bucket bottle separation and supply device which comprises a first bottom plate, a dripping bucket rail supporting plate and a top plate which are connected together through a plurality of supporting columns; the dripping bucket rail supporting plate is provided with a first material channel plate which is provided with N first rail grooves; the front end part of each first rail groove is provided with an optical fiber sensor; the first bottom plate is also provided with a second cylinder supporting plate which is provided with a second lifting cylinder; the piston rod end of the cylinder is connected with a material baffle plate; the device also comprises a second bottom plate which is provided with a third cylinder supportingplate; the supporting plate is provided with a third lifting cylinder; a second material channel plate is connected to the piston rod end of the cylinder and is provided with second rail grooves, corresponding to the first rail grooves; the material baffle plate is arranged between the first rail grooves and the second rail grooves; the device also comprises a compression mechanism used for compressing dripping bucket bottles in the first rail grooves; and the top plate is provided with a moving mechanism used for moving the dripping bucket bottles. The device provided by the invention can ensure that a material is not clamped between adjacent dripping bucket bottles and can ensure the subsequent technology to be successfully performed.

Owner:威海福瑞机器人有限公司

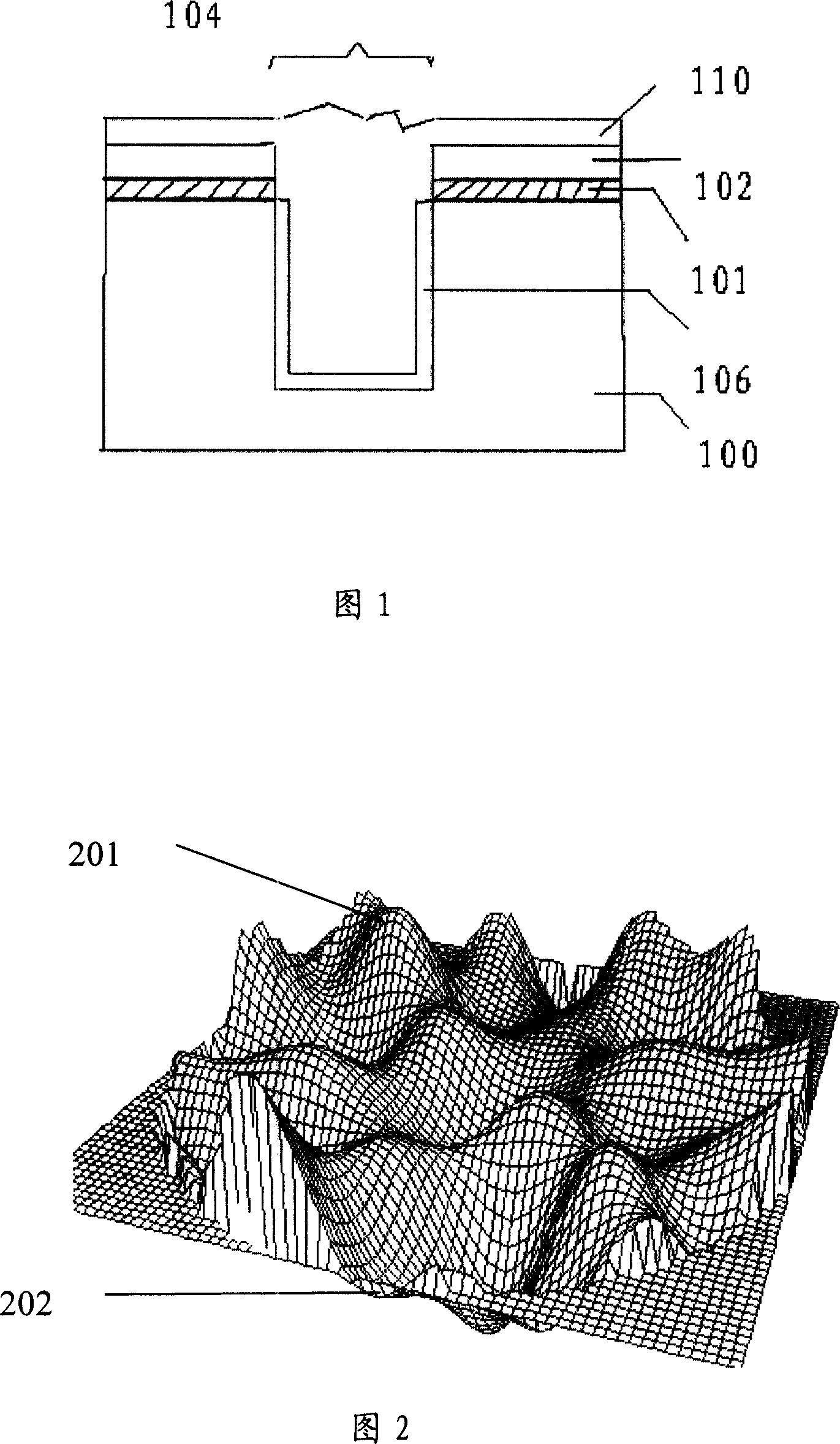

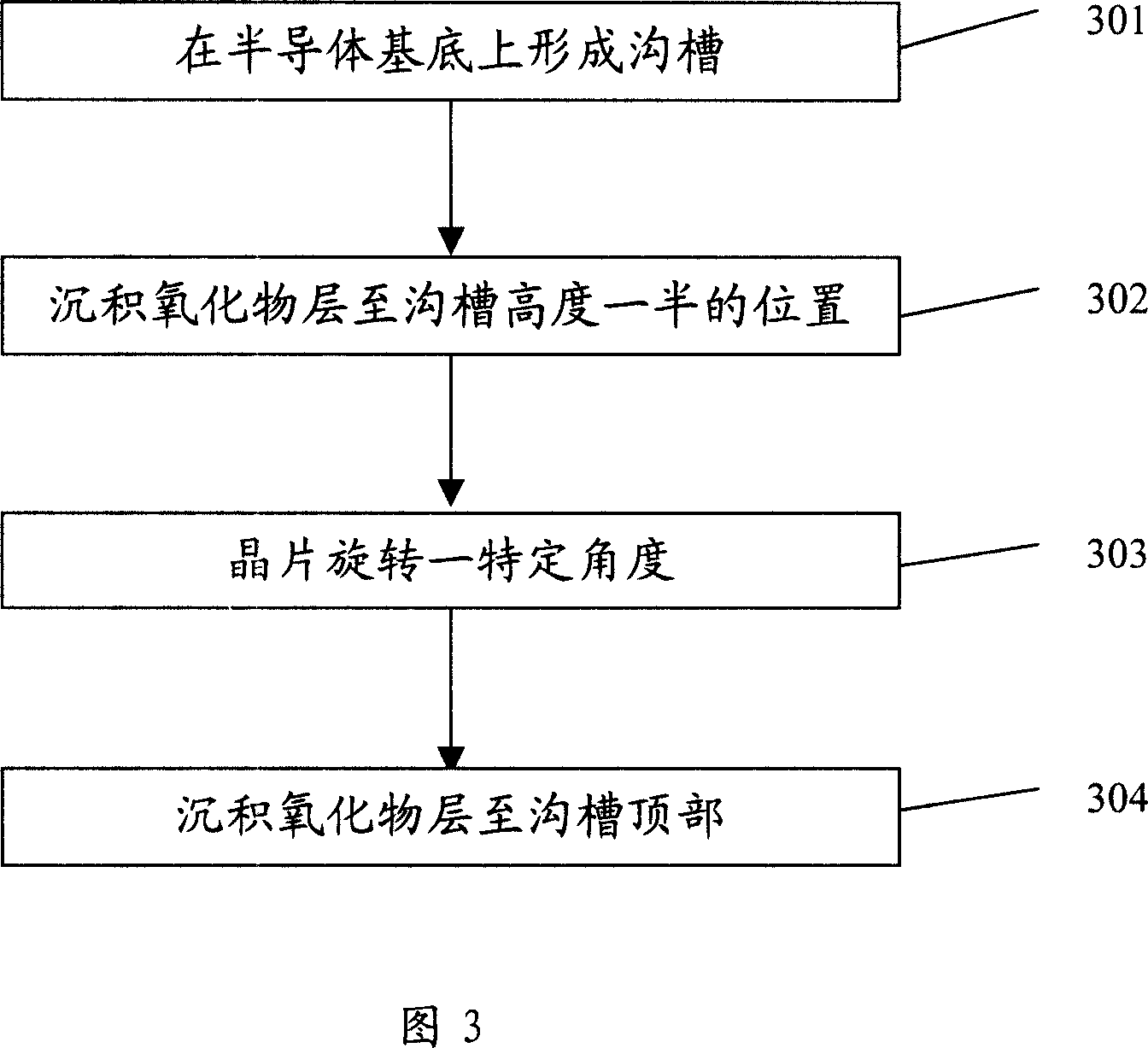

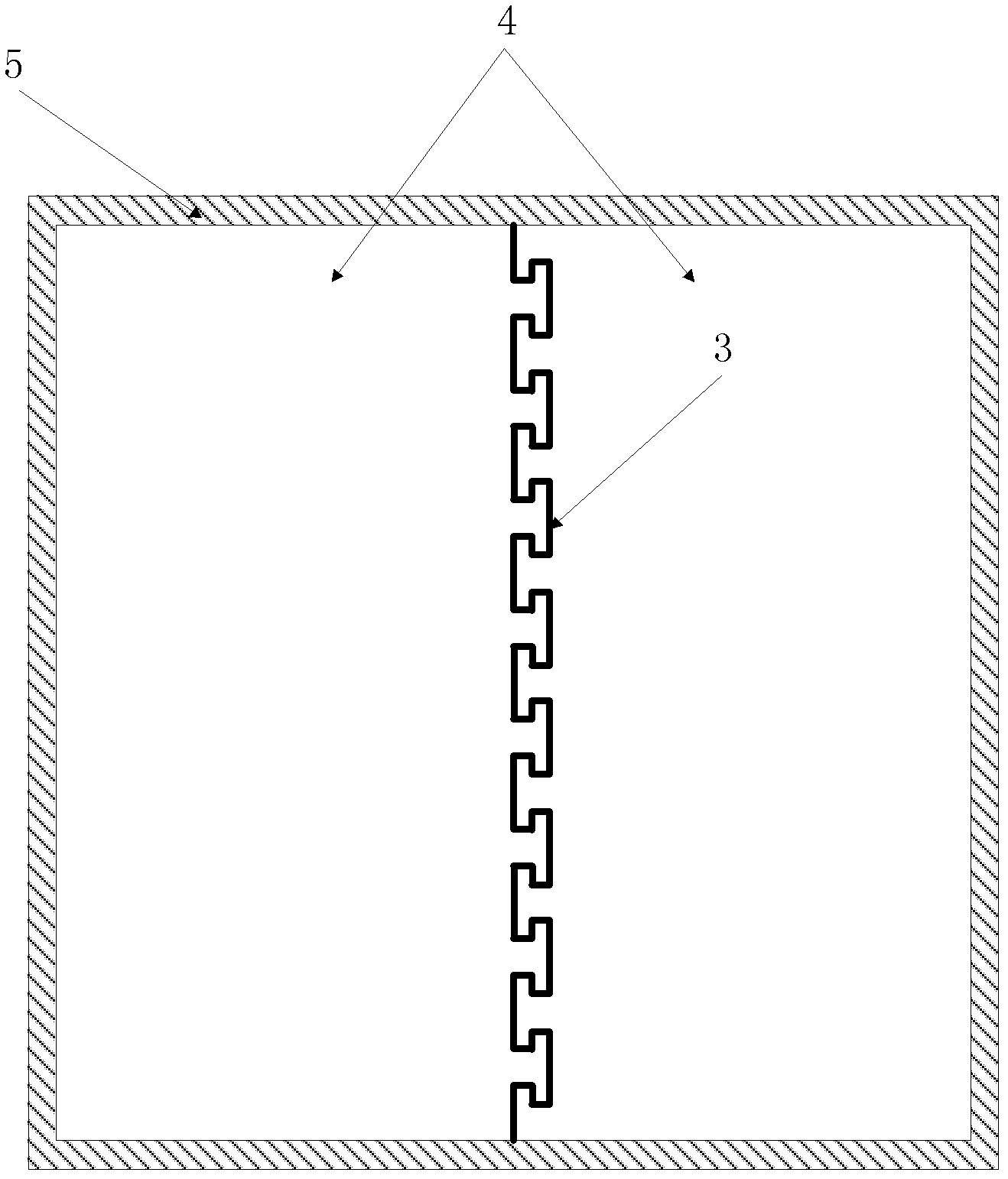

Filling method for isolation groove

InactiveCN101090088AGood surface smoothnessImprove surface roughnessSemiconductor/solid-state device manufacturingSurface roughnessEngineering

This invention discloses a filling method for isolating grooves including: a, forming a groove on a semiconductor base, b, depositing an oxide layer to the groove half of the height of the groove, c, rotating the wafer to a specific angle, d, depositing an oxide layer to the top of the groove, which can solve the problem that the surface roughness of the STI structure is large after solving the technical process of STI HDP and is ready for the CMP of next step.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

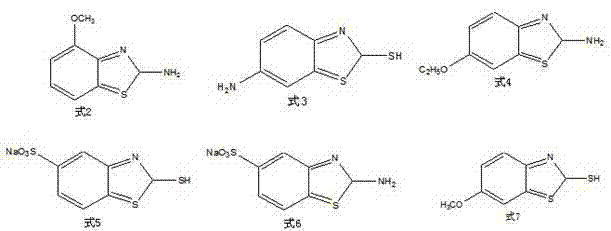

Film fading liquid composition with disubstituted benzothiazole as corrosion inhibitor

InactiveCN102830596AInhibitionEfficient removalPhotosensitive material processingChemistryLiquid composition

The invention relates to a film fading liquid composition with disubstituted benzothiazole as a corrosion inhibitor, relating to a film fading liquid for removing a dry film on the surface of an ultrathin copper circuit in the production process of the ultrafine circuit of a printed circuit board (PCB). The film fading liquid composition disclosed is prepared from the following ingredients of a) 6.0-10.0wt% of aliphatic amine, b) 0.5-2.0wt% of glycol ether organic solvent, c) 0.05-0.20wt% of corrosion inhibitor, and d) the balance being water, wherein disubstituted benzothiazole is used as the corrosion inhibitor. The film fading liquid composition is capable of quickly removing the film on the surface of the copper circuit without corroding the copper surface, and is good in a corrosion inhibition effect; and therefore the integrity of the circuit on the circuit board is thoroughly guaranteed and the quality of the circuit board is improved.

Owner:GUANGDONG TONESET SCI & TECH

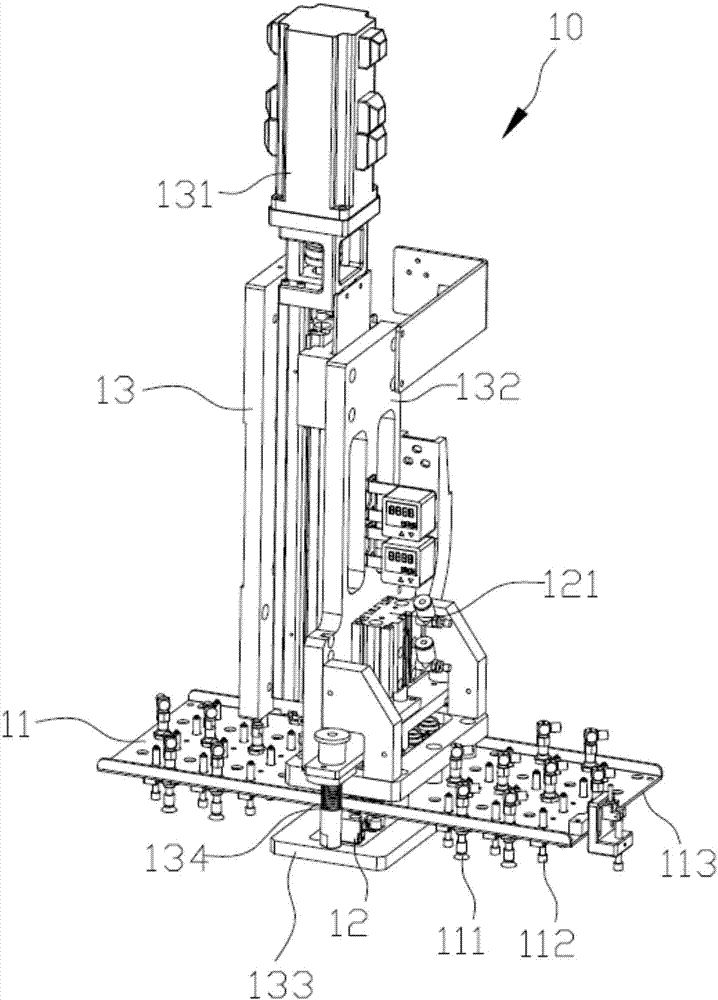

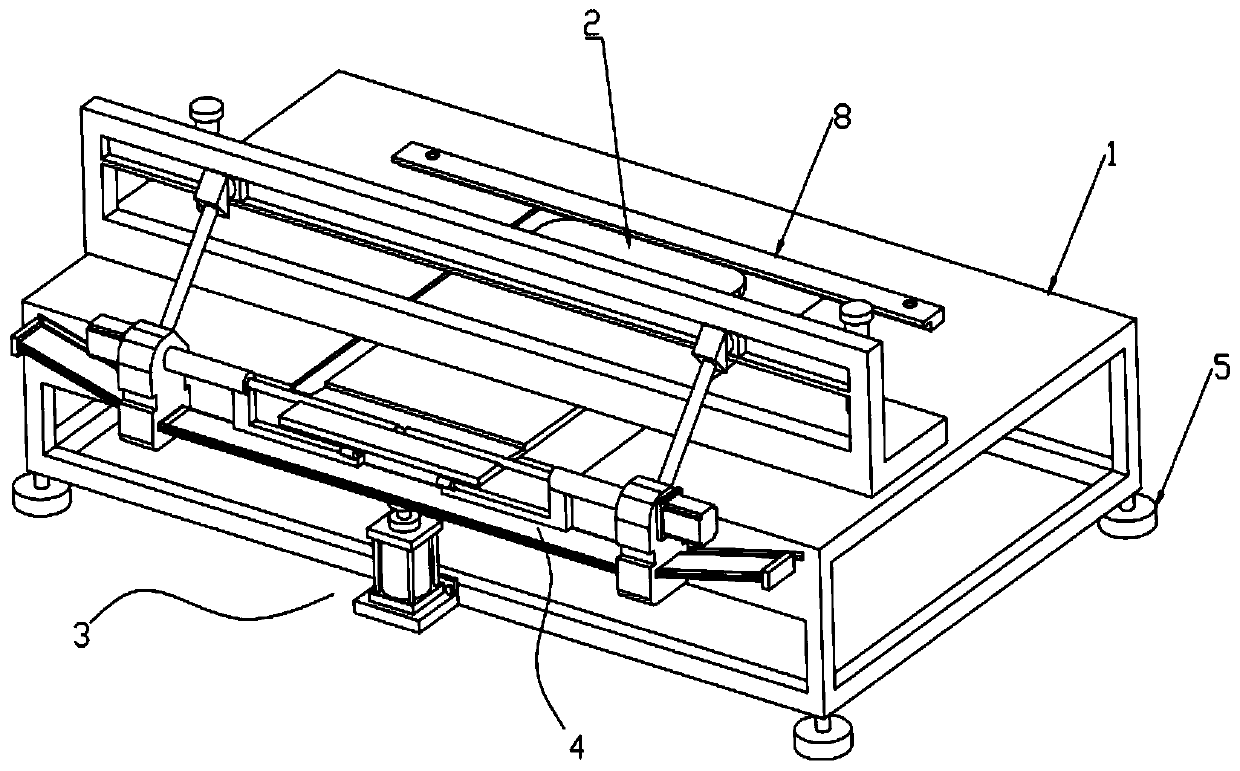

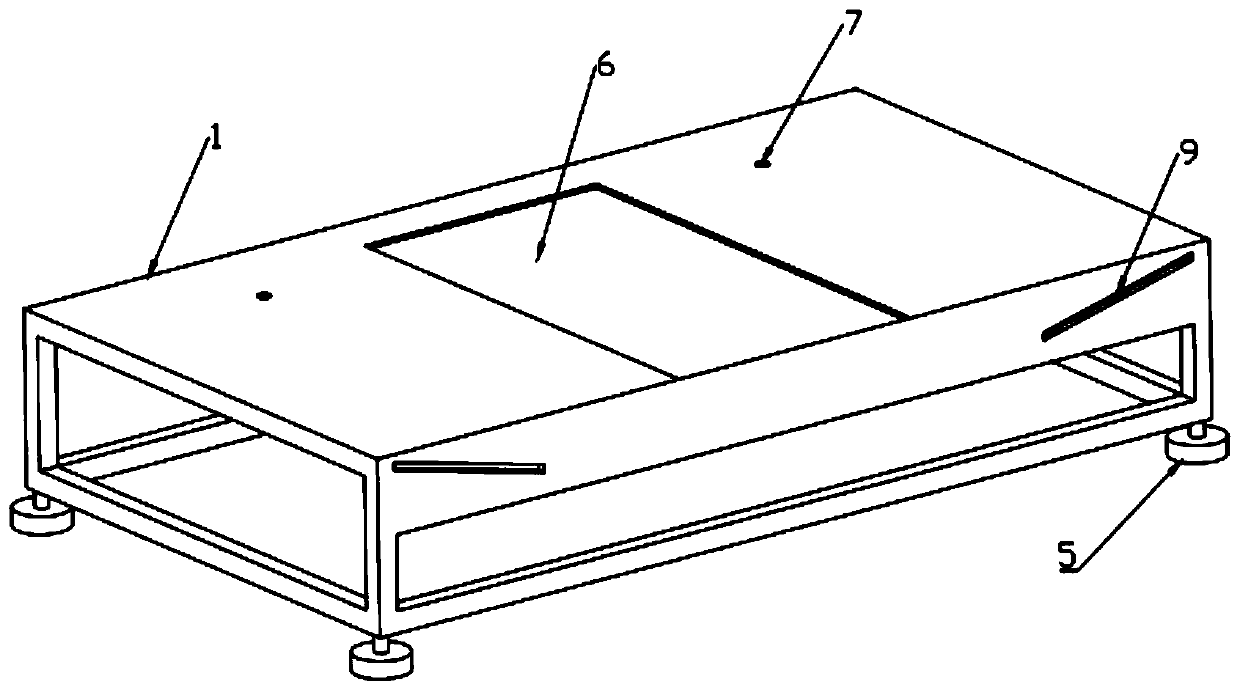

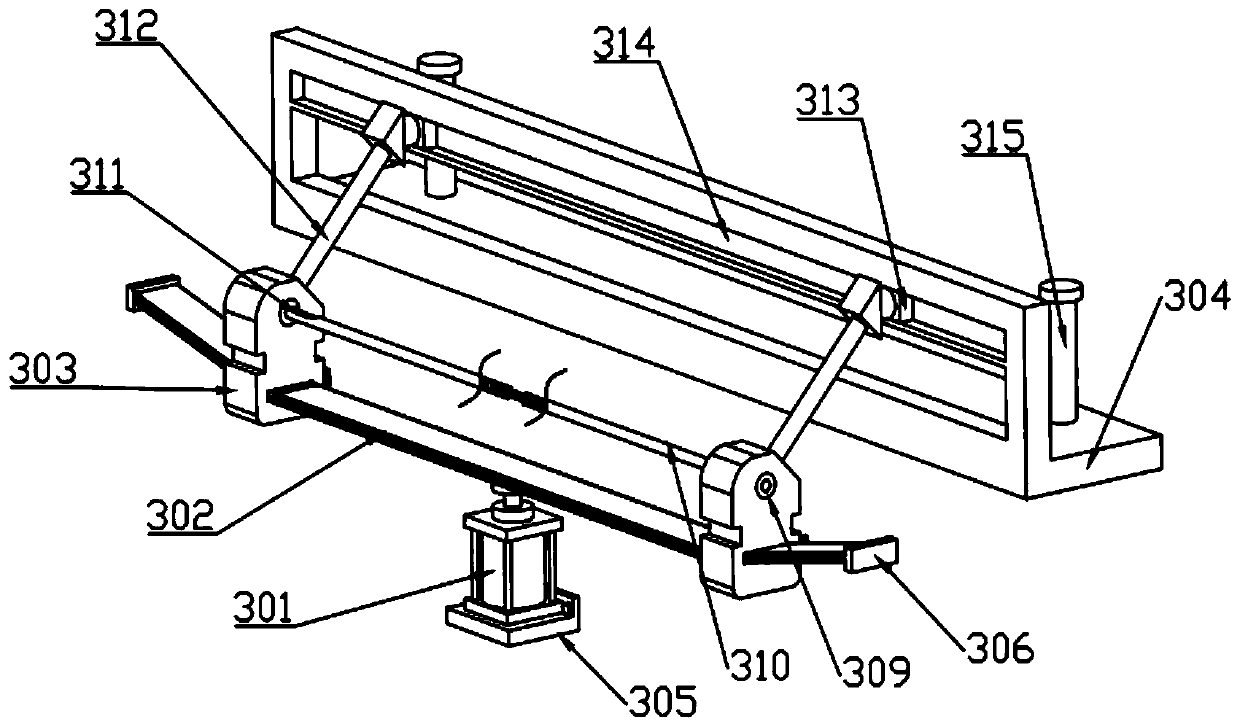

Separating feeding device for supporting pipe

InactiveCN109746748AEasy to separateRealize the feeding operationMetal working apparatusEngineeringAutomation

The invention provides a separating feeding device for a supporting pipe. The technical problems of complex operation and low efficiency of an existing feeding mode of pipes are solved. The separatingfeeding device for the supporting pipe comprises a carrying mechanism and a separating mechanism, the carrying mechanism comprises a carrying supporting frame, wherein a transverse moving base plateis arranged on the carrying supporting frame; a transverse moving air cylinder is arranged on the transverse moving base plate through an air cylinder fixing seat; sliding rails are further arranged above the transverse moving base plate; a lifting air cylinder connecting plate is arranged on sliding blocks of the sliding rails; the output end of the transverse moving air cylinder is connected tothe lifting air cylinder connecting plate; a lifting air cylinder is arranged on the lifting air cylinder connecting plate; a clamping jaw air cylinder is arranged at the bottom end of the lifting aircylinder; a clamping jaw is arranged at the output end of the clamping jaw air cylinder; and the separating mechanism is arranged under the clamping jaw; and the separating mechanism includes a separating supporting frame, a separating top plate is arranged on the separating supporting frame, a separating base plate is arranged on the separating top plate, a separating sliding channel is arrangedon the separating base plate, an ejecting vertical plate is arranged on the upper surface of the separating base plate, and an ejecting air cylinder is arranged on the ejecting vertical plate. The separating feeding device for the supporting pipe can be widely used in the field of industrial automation equipment.

Owner:威海福瑞机器人有限公司

Ultra-pure tinplate and preparation method thereof

ActiveCN113462952AQuality improvementImprove mechanical propertiesProcess efficiency improvementMetal rolling arrangementsSmelting processTitanium

The invention discloses an ultra-pure tinplate and a preparation method thereof. The preparation method comprises the following steps that in the tinplate smelting process, after initial adjustment of molten steel components is completed, fine adjustment is conducted on the molten steel components, and after fine adjustment is completed, continuous casting and rolling are conducted, and casting is conducted to form a casting blank or continuous casting is conducted to form a continuous casting blank; and when the molten steel components are finely adjusted, the temperature of molten steel is adjusted to 1,580-1,600 DEG C, then a titanium-containing deoxidizer is added into the molten steel, and after the reaction is conducted for 2-3 min, an aluminum wire is fed for deoxidation. According to the preparation method, the cleanliness of the molten steel can be improved, precipitation of a second phase can be promoted, the quality of the tinplate is improved, and finally the ultra-pure tinplate with excellent performance is obtained.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Color material mixing conveying device

InactiveCN107857074APrevent color lossAvoid getting lostConveyor partsMechanical conveyorsConveyor beltEngineering

The invention discloses a color material mixing and conveying device, which comprises a first conveyor belt and a second conveyor belt for conveying the color material, and the first conveyor belt and the second conveyor belt are arranged in a vertical layout up and down or obliquely up and down; the first conveyor belt The end is provided with a material guide groove for guiding the color material, and the two sides of the material guide groove are provided with a first barrier plate used to prevent the color material from being lost outward; the two sides of the initial end of the second conveyor belt are provided with Lost second blocking plate. Therefore, the present invention can prevent the loss of the color material, ensure the stable transportation of the color material, and facilitate the smooth progress of the follow-up process.

Owner:广东净雨环保科技有限公司

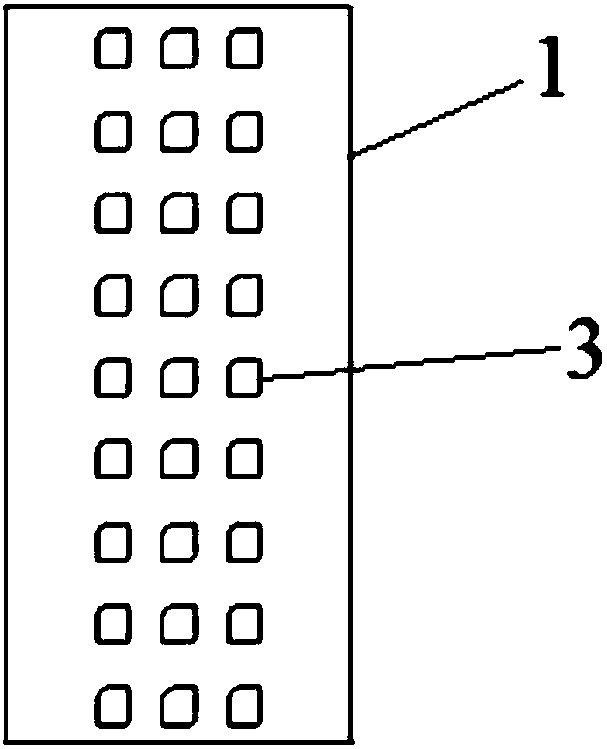

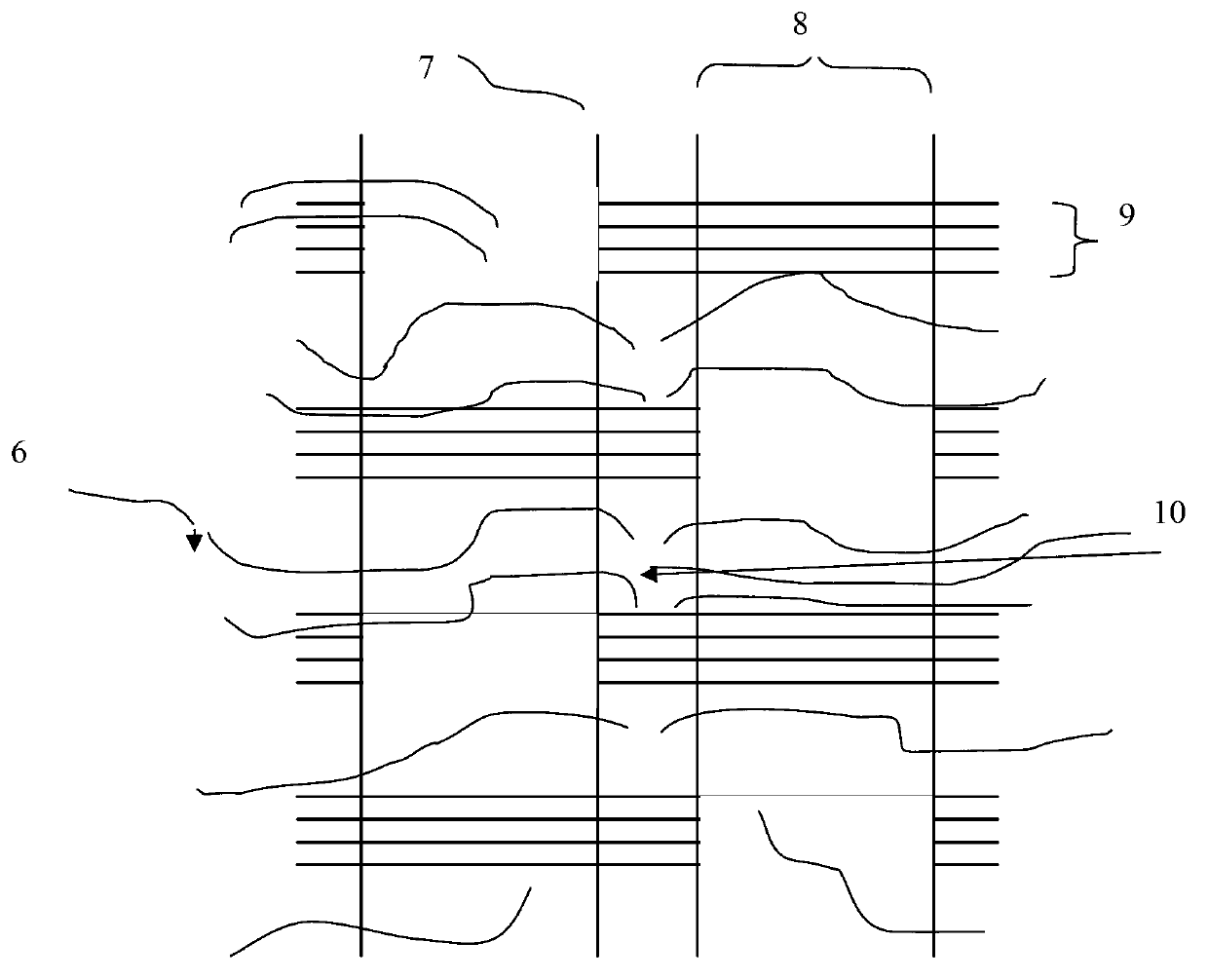

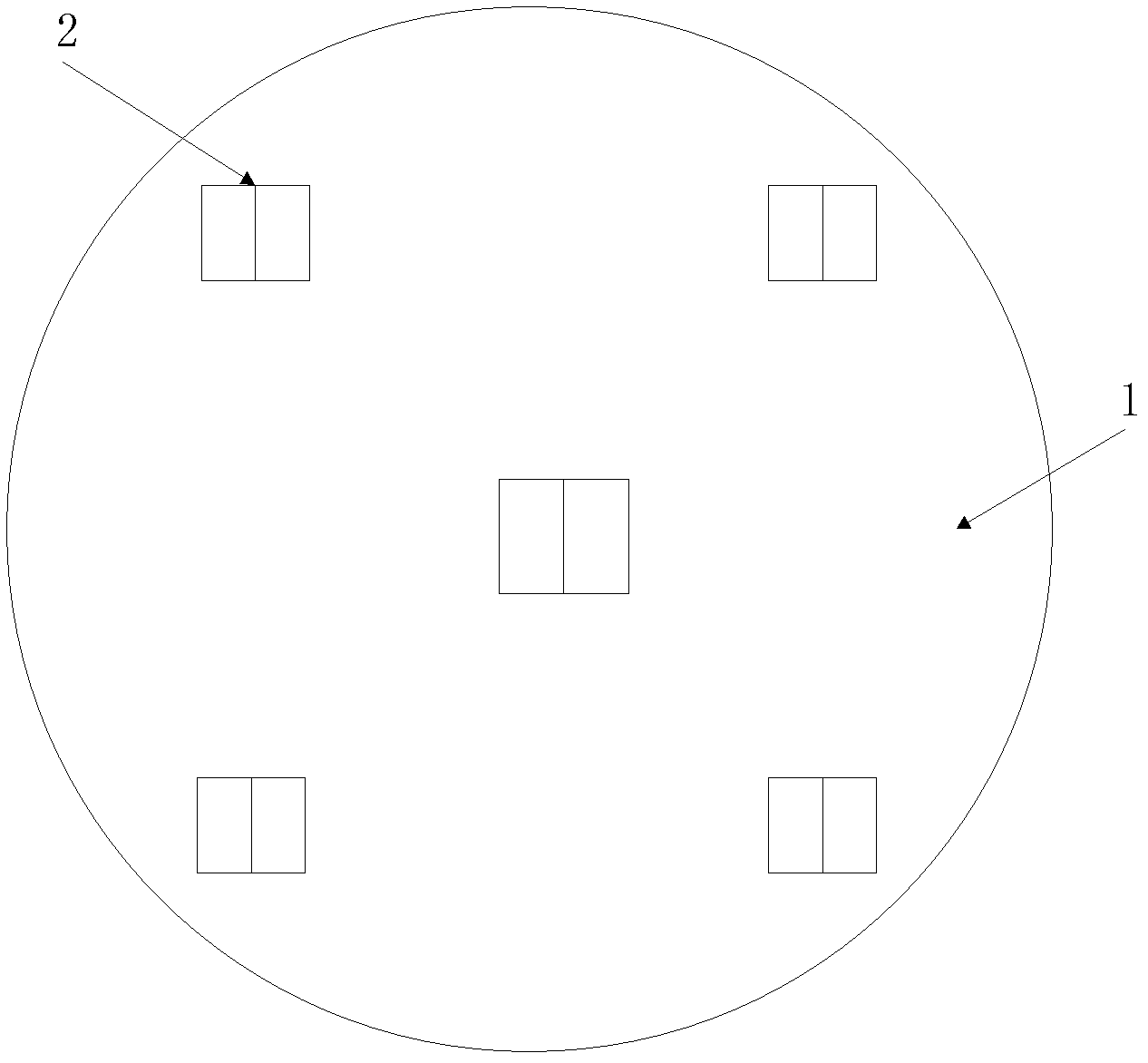

Structure and method for detecting whether narrow trench isolation grooves are etched to oxide layers based on silicon-on-insulator (SOI) silicon chip

ActiveCN102616729AGuaranteed mechanical strengthWill not cause severe over-etchingSolid-state devicesElectric/magnetic depth measurementElectrical resistance and conductanceInductively coupled plasma

The invention discloses a structure and a method for detecting whether narrow trench isolation grooves are etched to oxide layers based on a silicon-on-insulator (SOI) silicon chip, and belongs to the field of micro-opto-electro-mechanical system (MOEMS) devices. The detection structure comprises a plurality of test units 2, wherein one test unit 2 is arranged in the center of the SOI silicon chip on which devices are distributed, and the other test units 2 are distributed in the circumferential direction; and each test unit 2 is divided into two test areas 4 by narrow grooves 3. The method comprises the following steps of: during etching, measuring a resistance value between the two test areas 4, and if the resistance value is more than 0, continuously etching; and if the resistance value between the two test areas 4 in each test unit 2 tends to be infinite, indicating that the trench isolation grooves on the devices are etched to the oxide layers. The structure and the method have the advantages that the inductively coupled plasma (ICP) etching condition is reflected by the change of the resistance value which is measured in real time, and the condition of severe over etching is avoided.

Owner:XI AN ZHISENSOR TECH CO LTD

Environment-friendly waste oil tower pipe type countercurrent process radiation heating and acid-free oil extraction technology

InactiveCN108395903AHigh yield and purityAvoid cokingTreatment with plural serial refining stagesHydrocarbon oils treatment productsSolventElectricity

The invention relates to the technical field of waste oil recycling and in particular relates to an environment-friendly waste oil tower pipe type reverse-flow-process radiation heating and acid-freeoil extraction technology. According to the technology, electric radiation heating is adopted so that risks of fire heating are avoided, and solvent extraction is utilized so that acid and alkali hazard is solved; a reverse reaction technology is utilized so that the quality of a product is improved; an extracting agent is utilized so that the recycling rate is improved and a coking and blocking phenomenon is also extremely avoided; meanwhile, the production cost is also saved and the quality of recycled oil is improved; waste oil is mixed with an organic solvent so that the oil is dissolved in the organic solvent and impurities also can be washed in a sediment form; then the impurities can be completely separated from the oil through a filtering effect of a screen mesh so that the purityand yield of the recycled oil are improved; the extracting agent in an extracting system is used for continuously extracting filtrate and a micro-catalysis effect is realized, so that smooth proceeding of a subsequent procedure is facilitated; the waste oil is recycled so that resources are saved and pollution to the environment is also reduced, so that the technology accords with an environment-friendly development concept advocated in modern times.

Owner:张荣江

Intelligent control material mixer

The present invention relates to an intelligent control material mixer, which comprises a V-shaped material mixing hopper, wherein a material inlet is arranged above the V-shaped material mixing hopper, a conveying pipe is arranged outside the V-shaped material mixing hopper and is provided with a material conveying pipe communicated to the conveying pipe, the other end of the material conveying pipe is connected to a material feeding bin, the conveying pipe is further provided with a compressed air pipe communicated to the conveying pipe, the front end of the conveying pipe is provided with an atomizing spraying nozzle, the atomizing spraying nozzle is positioned inside the V-shaped material mixing hopper, the conveying pipe is provided with a control valve, the compressed air pipe is provided with an opening / closing switch, and an intelligent control cabinet is arranged outside the V-shaped material mixing hopper and can control the control valve so as to control the conveying amount. According to the present invention, the structure is simple, the manufacturing cost is low, the water content or the additive capacity can be controlled, and the atomizing spraying nozzle is additionally arranged to effectively make the water or additive and the material be completely and uniformly mixed so as to effectively ensure the smooth performing of the subsequent process.

Owner:YANGZHOU SANSHAN IND CERAMICS

Bending device for heat dissipation inserting slice in radiator for 5G base station

ActiveCN111408638AEffective immobilizationEffective limitMetal-working feeding devicesHeat exchange apparatusEngineeringHeat spreader

The invention discloses a bending device for a heat dissipation inserting slice in a radiator for a 5G base station, and relates to the technical field of communication. The bending device comprises abase frame, a heat dissipation slice, a pressing mechanism and a bending mechanism; the lower end of the base frame is provided with a plurality of supporting feet in the circumferential direction; the upper end surface of the base frame is provided with a placement groove, and the two sides of the placement groove are provided with installation holes; and limiting pieces are detachably connectedto the interiors of the two installing holes through bolts. According to the bending device, by arranging the placement groove with the width far larger than that of the heat dissipation slice on theupper surface of the base frame and arranging the pressing mechanism and the limiting pieces, the machining efficiency is improved to a great extent; by arranging the bending mechanism, it is achieved that the heat dissipation slice can keep in a vertical state after being connected to a base in a swelling pressing mode so that it can be ensured that subsequent procedures are carried out successfully; and by connecting two symmetrically-arranged abutting bent rods in an inserting connection mode, the supporting strength of the bent portion in the bending process is ensured, and meanwhile, thepurpose of successfully separating a heat dissipation plate after bending from the bending device can be achieved.

Owner:WUHU JINYI MACHINERY

Recycling device used for papermaking advanced treatment wastewater and based on chemical decalcification

InactiveCN103253838BOvercome defects such as polluting the environmentEmission reductionGeneral water supply conservationMultistage water/sewage treatmentElectrolysisFiltration

The invention discloses a papermaking advanced treatment waste water recycling device based on chemical decalcification, which includes a chemical decalcification system, a filtration system, an electrolysis system, a membrane separation system and a desalination system. The chemical decalcification system is equipped with a dosing system and a membrane separation system. It is one of ultrafiltration system and MBR system. The present invention combines chemical decalcification technology, electrochemical technology and membrane technology, and 70% to 85% of papermaking advanced wastewater treatment can be recycled and recycled, which not only reduces wastewater discharge, avoids environmental pollution of wastewater, but also reduces waste of water resources , It can also make the cost of regenerated circulating water lower than the price of tap water, which is economically reasonable, produces better economic benefits, greatly reduces the water consumption index and wastewater discharge index of tons of paper, and improves the economic and technical indicators of the enterprise.

Owner:BOYING XIAMEN SCI & TECH

An improved textile bobbin

The invention relates to an improved spinning spool which comprises a winding shaft and side plates. The side plates are arranged at the ends of the winding shaft, the winding shaft is used for winding yarn, the two ends of the side plates are arranged on a spinner through installing grooves, lifting mechanisms are arranged at the top ends of the side plates, and a movable mechanism is arranged between the lifting mechanisms; the winding shaft is used for winding yarn, the side plates block the yarn from the two sides, the yarn is prevented from being scattered, the lifting mechanisms can drive the movable mechanism to move up and down, meanwhile, the movable mechanism is movable so as to adapt to yarn outlet operation of yarn at different positions, the movable mechanism comprises a movable branch chain and a guiding rod, the guiding rod is horizontally arranged between the lifting mechanisms, and the guiding rod is used for guiding the movable branch chain to move horizontally. Stability maintenance processing can be performed on the yarn, yarn swing repeating is reduced, and the yarn is prevented from being pulled apart; the dryness close to the spinning spool is lowered, the phenomenon that static electricity is generated in the yarn outlet process is avoided, and it is ensured that the follow-up procedures of the yarn can be performed successfully.

Owner:杭州余杭宏强丝绸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com