Color material mixing conveying device

A technology for conveying equipment and pigments, applied in conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of wasting pigments, scattering pigments, affecting the production process, etc., and achieving the effect of preventing pigments from being lost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

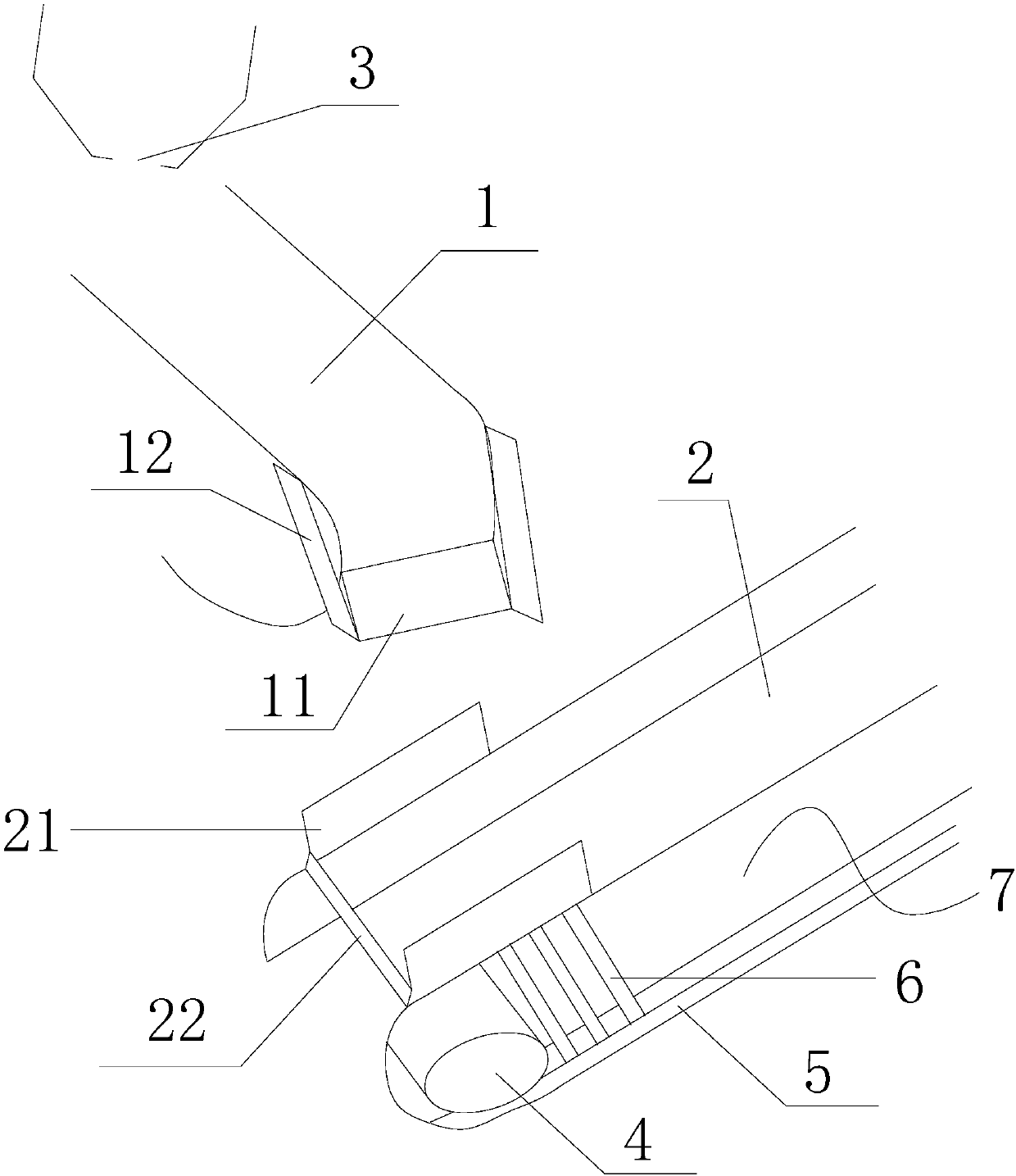

[0014] refer to figure 1 , a color material mixing and conveying device of the present invention, comprising a first conveyor belt 1 and a second conveyor belt 2 for conveying the color material, and the first conveyor belt 1 and the second conveyor belt 2 are arranged in a vertical layout up and down or obliquely; The end of the first conveyor belt 1 is provided with a material guide groove 11 for guiding the color material, and the both sides of the material guide groove 11 are provided with the first blocking plate 12 for preventing the color material from dispersing outwards; The side is provided with the second blocking plate 21 for preventing the colorant from escaping outwards.

[0015] Specifically, the first conveyor belt 1 and the second conveyor belt 2 are arranged up and down or obliquely up and down, which means that the first conveyor belt 1 and the second conveyor belt 2 are both parallel to the ground or at the same angle with the ground; the first conveyor bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com