Manufacturing method for light emitting diode (LED) metal base board

A technology for light-emitting diodes and metal substrates, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of difficult splintering of metal substrates, difficult processes, weak bonding strength, etc., to meet large-scale industrial production, and the process method is simple and reliable. , the effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Method steps of the present invention are as follows:

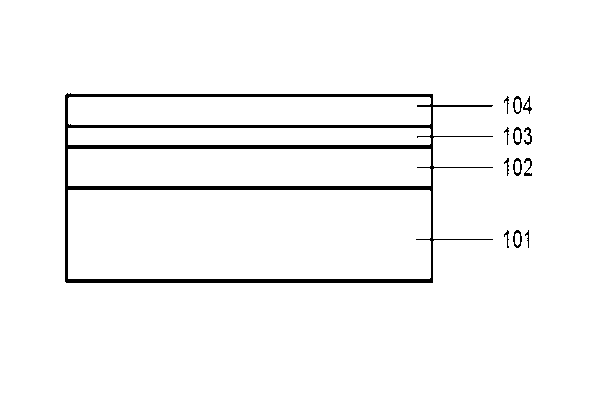

[0023] see figure 1 , growing an N-type GaN-based semiconductor layer 102, a quantum well active region 103, and a P-type GaN-based semiconductor layer 104 sequentially on a sapphire substrate 101 by metal-organic chemical vapor deposition;

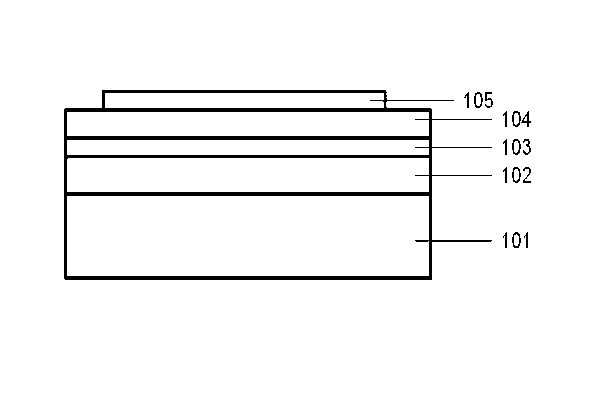

[0024] see figure 2 , on the P-type GaN-based semiconductor layer 104, vapor-deposit a metal layer reflector 105 with a thickness of 1000-10000 Å; anneal at a high temperature for 10-30min in a nitrogen atmosphere to form a gap between the metal reflective layer 105 and the P-type GaN-based semiconductor layer 104 Ohmic contact, and enhance the bonding force between the two;

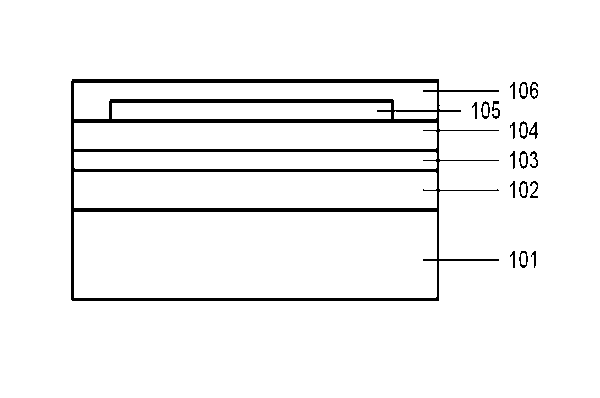

[0025] see image 3 , sputtering one or more layers of metal on the metal reflective layer 105 and the P-type GaN-based semiconductor layer 104 as the seed layer 106; using photolithography and wet chemical etching to form the seed layer 106 on the position that will need splits in the future ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com