Waste heat recovery device and process for dusty flue gas

A waste heat recovery device and waste heat recovery technology, applied in the direction of reducing greenhouse gases, climate sustainability, lighting and heating equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

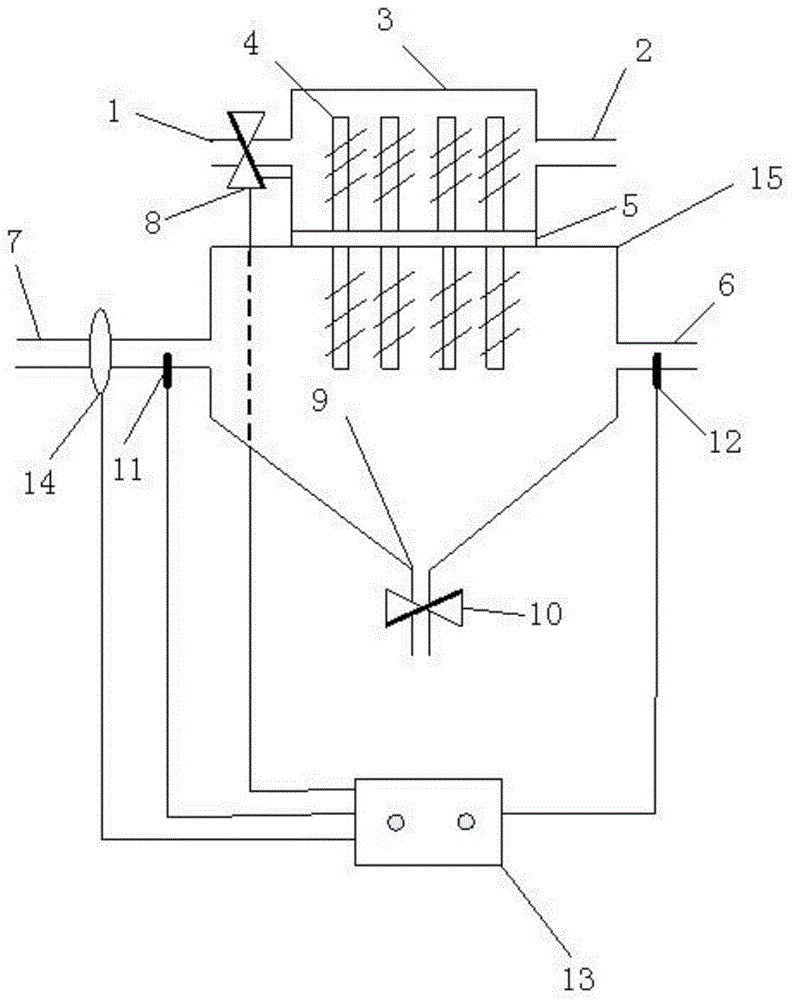

[0050] A waste heat recovery device for dusty flue gas such as figure 1 As shown, it includes a shell, a heat pipe 4 and a heat shield 5 . The housing is divided into upper and lower parts by the heat insulation board 5, which are respectively the upper housing 3 and the lower housing 15. The two sides of the upper housing 3 are respectively provided with a cold water inlet 1 and a hot water outlet 2, and the two sides of the lower housing 15 are respectively A flue gas inlet 7 and a flue gas outlet 6 are provided. The bottom of the lower shell 15 is provided with a smoke and dust outlet 9, and a valve 10 is installed at the smoke and dust outlet 9. The upper shell 3 is square, and the lower shell 15 is a cone with a cone angle of 60°. Conical shape; a heat pipe 4 is installed on the heat shield 5, one end of the heat pipe 4 is located in the upper housing 3, and the other end of the heat pipe 4 is located in the lower housing 15; the cold water inlet 1 is equipped with an ele...

Embodiment 2

[0053] Utilize the device described in embodiment 1 to carry out waste heat recovery of dusty flue gas:

[0054] Set the flow rate to 50000m 3 / h, the dust-containing flue gas with a temperature of 300°C enters the lower housing 15 through the flue gas inlet 7, the number of heat pipes is 32, and the length of the heat pipes in the lower housing is 2 / 3 of the total length of the heat pipes. The gas exchanges heat with the heat pipe 4 in the lower shell, and is discharged through the flue gas outlet 6. At this time, the temperature of the flue gas can drop to 150°C, and the smoke and dust settle in the lower shell 15. The waste heat recovery device works for half a month and opens the valve 10 to clean the dust. , to avoid dust deposition blocking the flue gas outlet 6. The waste heat recovery efficiency at this time was 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com