Flexible base with protecting layer

A flexible base and protective layer technology, applied in the direction of the launch device, can solve the problems of ablation and damage of the launch base, affecting the life of the launch base, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

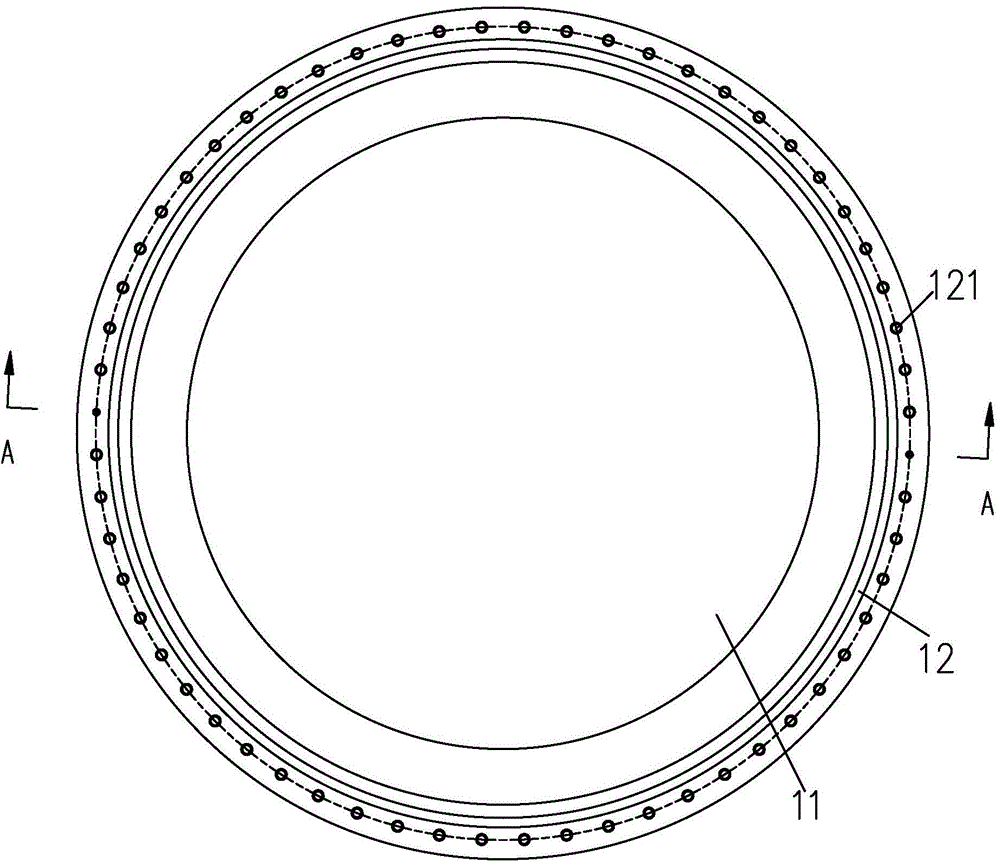

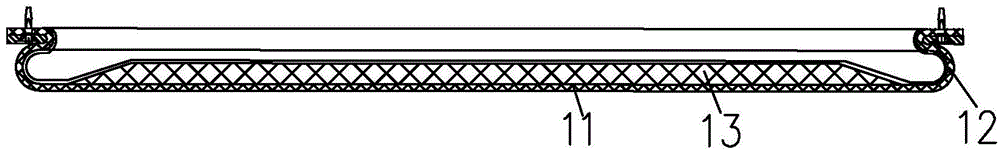

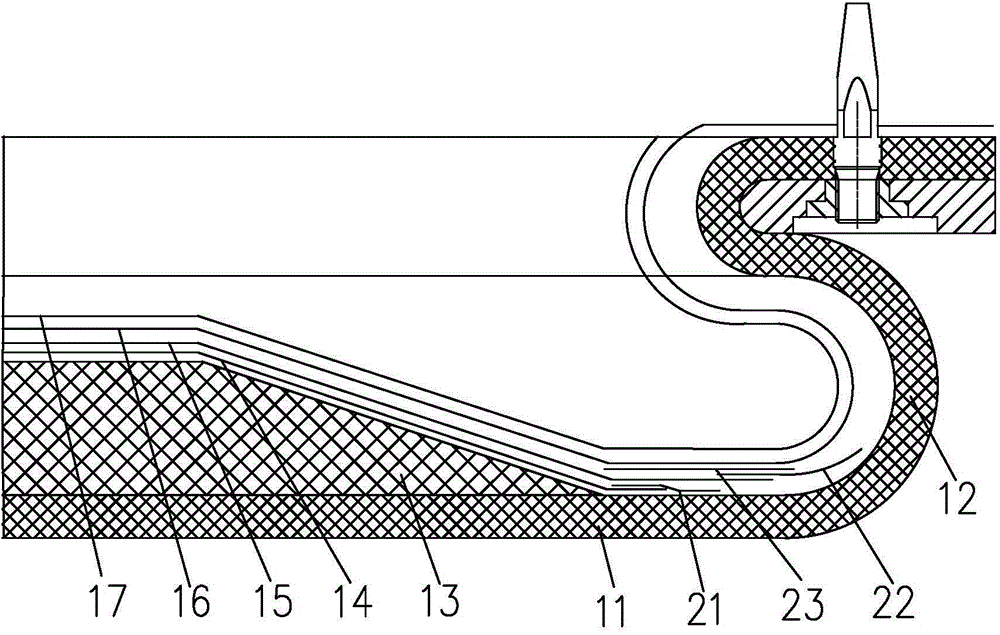

[0017] Such as figure 1 , 2 As shown, the flexible base with protective layer of the present invention includes a bottom plate 11 and a side wall 12. The bottom plate 11 and the side wall 12 are made of nylon / rubber tape material, and the bottom plate 11 and the side wall 12 form a barrel shape. The inner surface is provided with a reinforcing layer 13, which is made of rigid foam material, such as image 3 As shown, the reinforcing layer 13 is sequentially bonded with a butyl rubber sheet 14 and an aramid tape 15 from the inside to the outside. The aramid tape 15 and the inner surface of the side wall 12 are pasted with a shielding layer 16, and the shielding layer 16 is electromagnetic Shielding cloth, the shielding layer 16 is pasted with a butyl tape 17, the thickness of the butyl tape 14 is 0.5 mm, the thickness of the aramid tape 15 is 1.0 mm, and the thickness of the butyl tape 17 is 0.3 mm.

[0018] A first crimping protection plate 21 is bonded between the edge of the but...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com