Touch screen with force feedback system

A touch screen and force feedback technology, applied in the input/output process of data processing, input/output of user/computer interaction, instruments, etc., can solve the problem of reducing user experience, unrealistic tactile feedback, and meaningless signal processing burden of the touch system and other issues to achieve the effect of real touch sense and improved touch experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

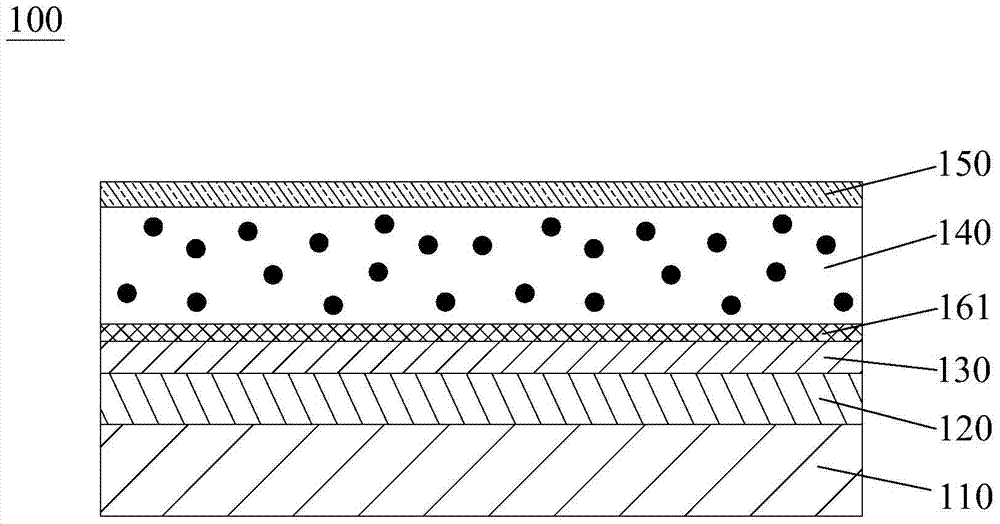

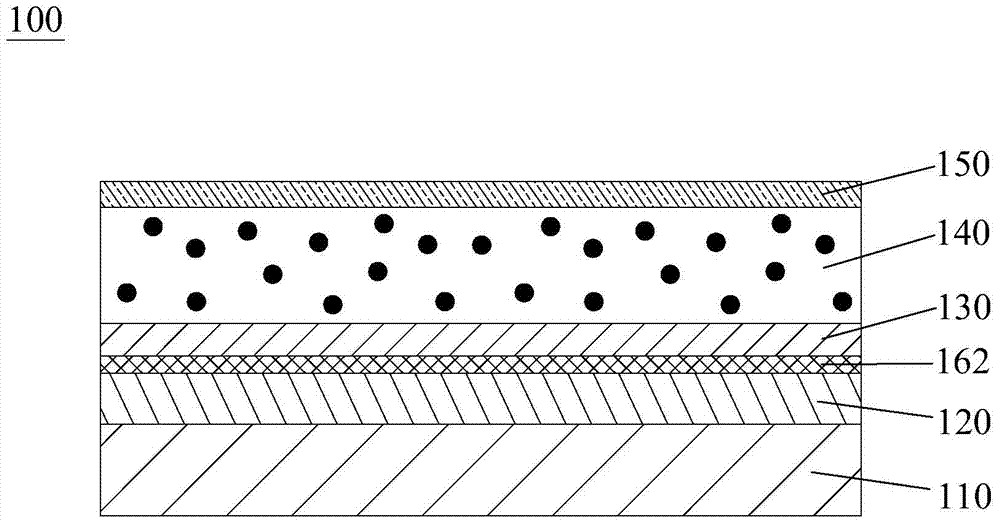

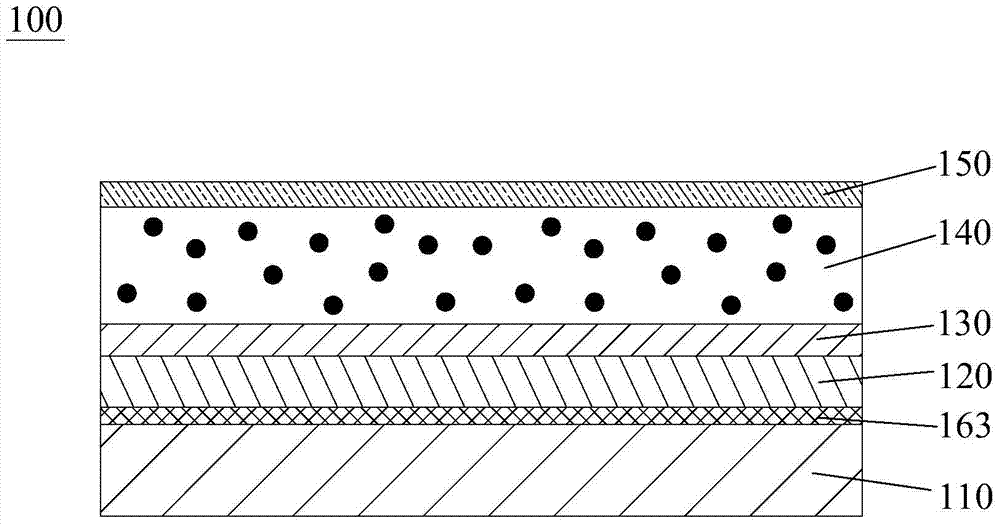

[0042] Such as Figure 1-Figure 5 As shown, the touch screen 100 with a force feedback system provided by the present invention has a touch layer 120 and a cover plate 130 for protecting the touch layer 120, and the touch layer 120 is located on the lower side of the cover plate 130; The touch screen 100 also includes a magnetic fluid layer 140 , a protective film 150 disposed on the magnetic fluid layer 140 , and electromagnetic induction layers 161 - 165 electrically connected to the touch layer 120 . The magnetic fluid layer 140 is disposed on the cover plate 130 On the upper side, the protective film 150 is disposed on the upper side of the magnetic fluid layer 140, the electromagnetic induction layers 161-165 are disposed on the lower side of the magnetic fluid layer 140, and the electromagnetic induction layers 161-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com