Trolley for precast bricks

A technology of prefabricated bricks and trolleys, applied in the direction of trolleys, multi-axis trolleys, trolley accessories, etc., which can solve the problems of low service life and low safety performance of the trolley, so as to improve the service life, improve the placement efficiency, and reduce the danger of pinching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

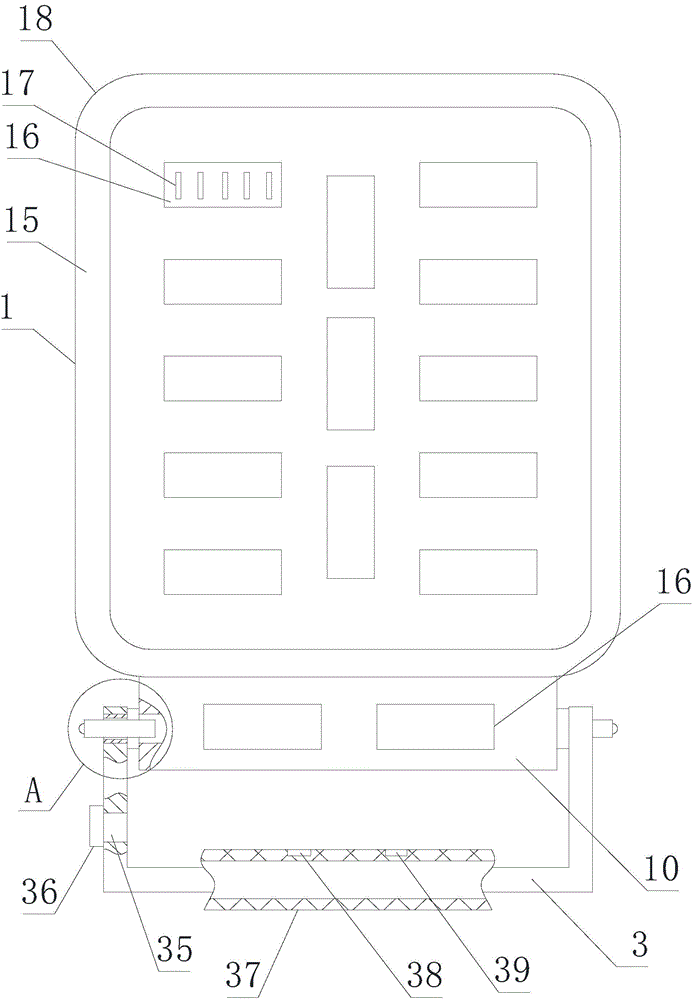

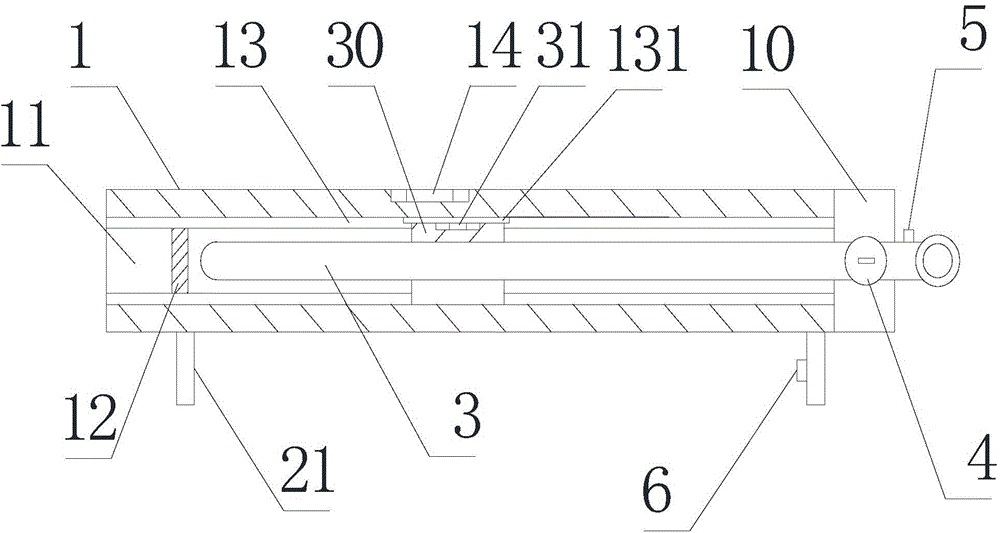

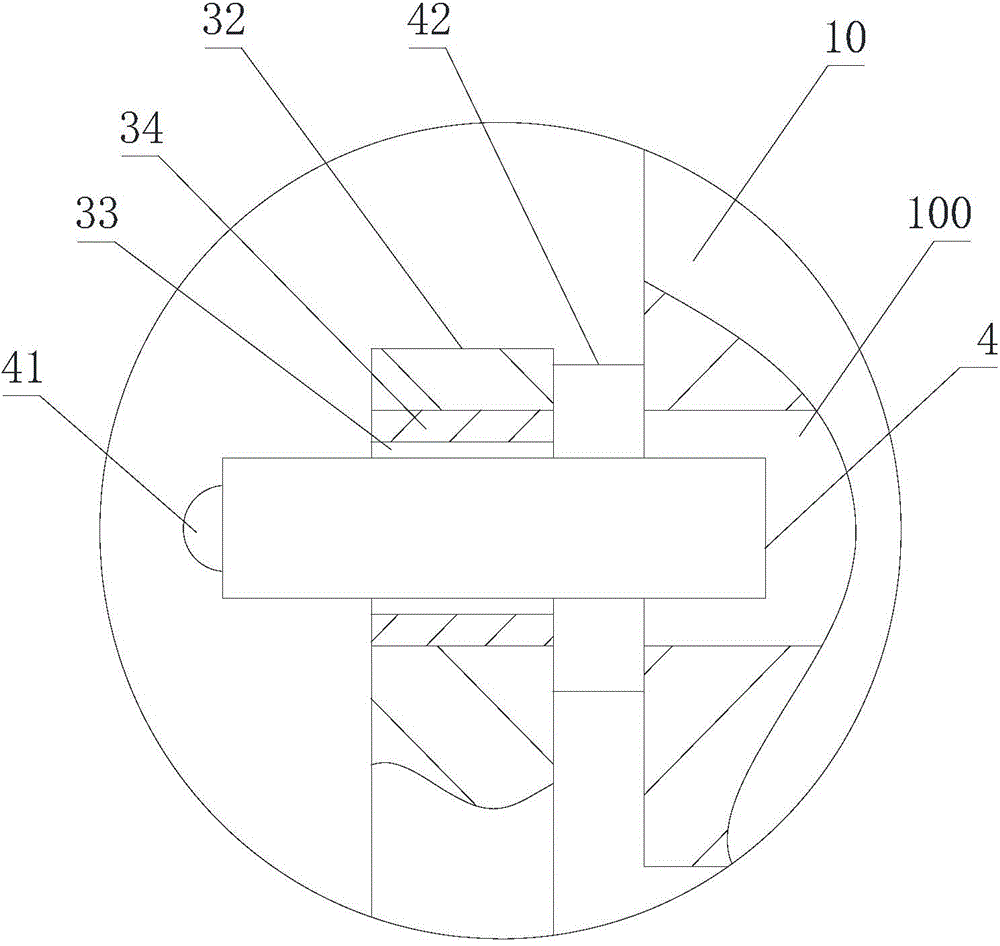

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a handcart for prefabricated bricks includes a base plate 1, a roller 2 fixedly connected to the base plate 1, and a handle 3. Both ends of the base plate 1 are provided with a placement groove 11 for placing the handle 3. The front end of the groove 11 is provided with a limit baffle 12, and the front end of the base plate 1 is provided with a mounting block 10 which is convenient for the installation of the handle 3. The width of the mounting block 10 is equal to the distance formed by two placing grooves 11 on the base plate 1, so The placement groove 11 is provided with at least one guide rail 13 which is convenient for the handle 3 to slide in the placement groove 11. The handle 3 is provided with a slider 30 matching the guide rail 13. The slider 30 is provided with at least one The slider 30 is locked on the electromagnet 31 in the guide rail 13. At least one piece of metal sheet 131 is provided in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com