Labelling equipment that prints labels online

A labeling and labeling technology, applied in the field of labeling equipment, can solve the problems of low efficiency, waste of time in printing labels and label replacement, and low efficiency, and achieve the effect of shortening labeling time, improving work efficiency and simplifying operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

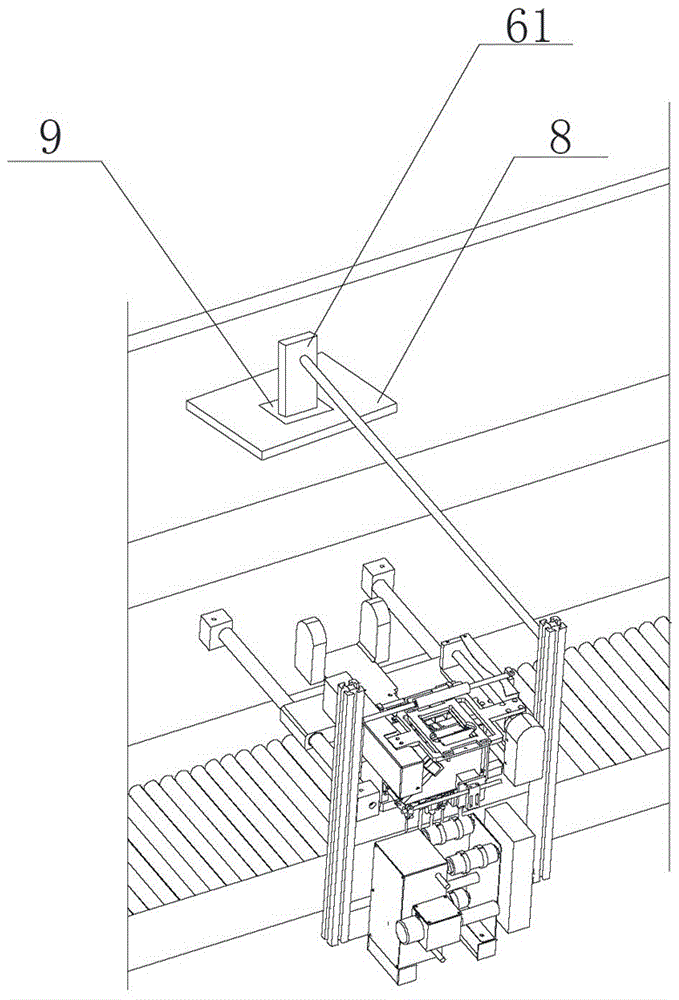

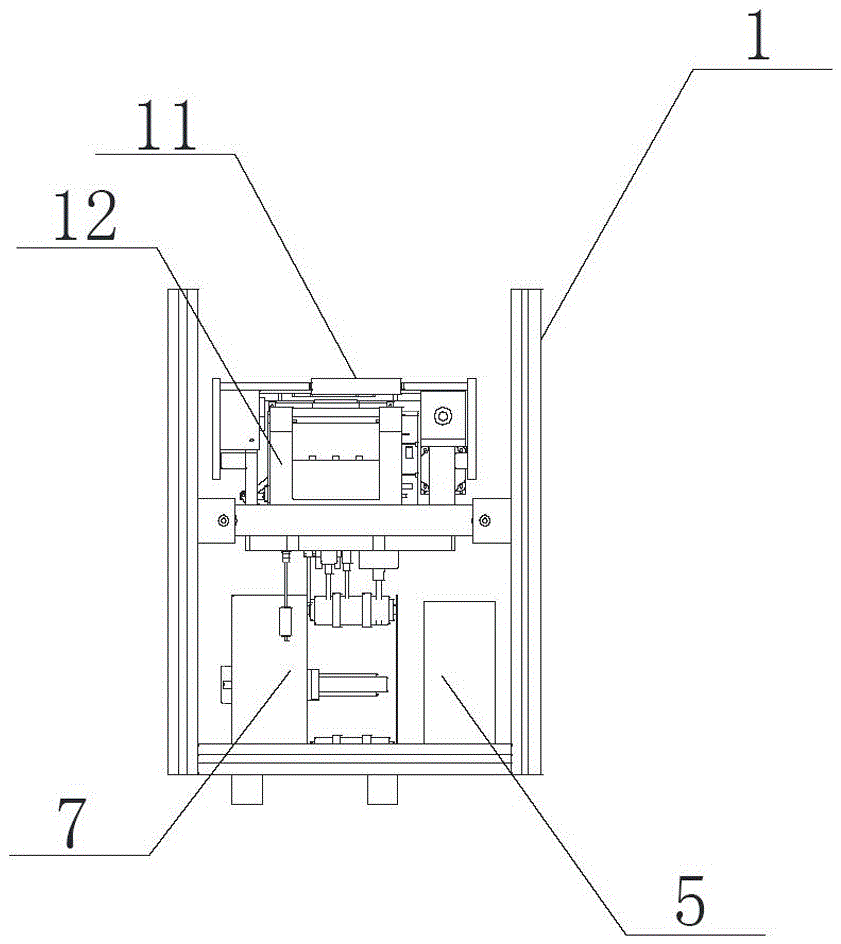

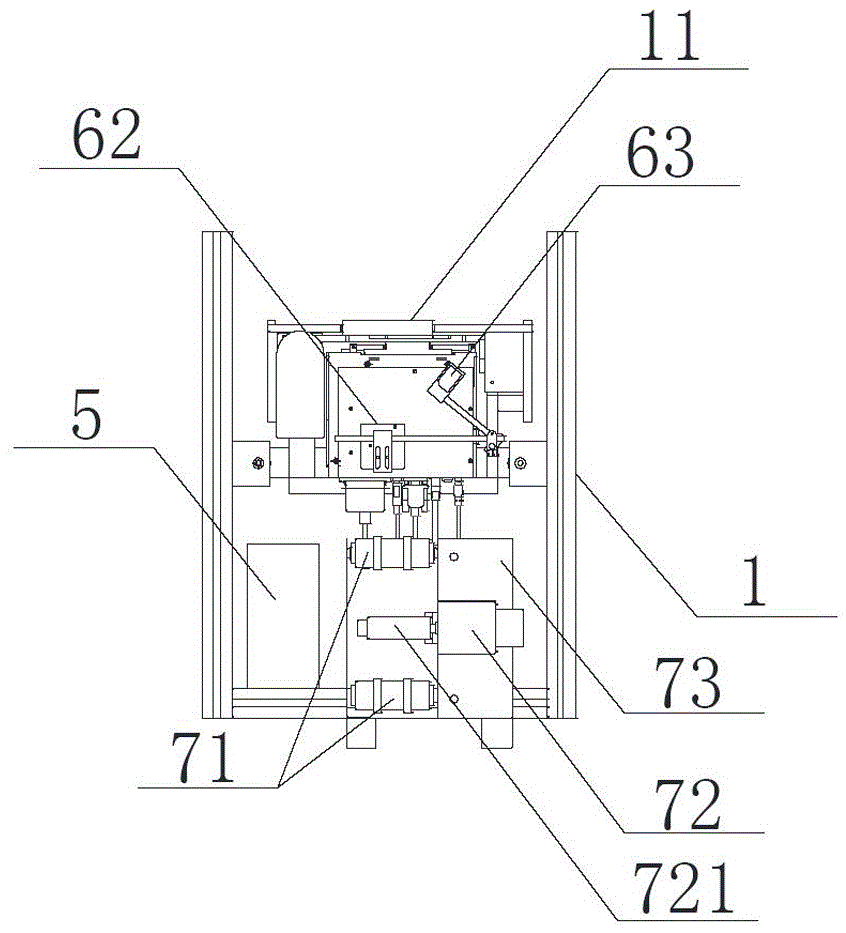

[0047] This embodiment is the most preferred for implementing the present invention. like Figure 1-8 As shown, the labeling equipment in this embodiment includes: a mounting frame 1; a carrier group 2, which is arranged on the mounting frame 1; a carrier group driving device 3, which is used to drive the carrier group 2 for translational movement, The carrier group driving device 3 is also arranged on the mounting frame 1, and it is connected with both ends of the carrier group 2; the label printer 4 is also arranged on the mounting frame 1, and is arranged below the carrier group 2, The paper outlet 41 place on this label printer 4 is also provided with dial tongue 42, and this dial tongue 42 is also positioned at the below of the end point of the moving stroke of carrier group 2; The tool set driving device 3 and the label printer 4 are used to control the carrier set driving device 3 and the label printer 4, mainly including commands for controlling start and stop, and ar...

Embodiment 2

[0065] Others are the same as those described in Embodiment 1, except that the driving device of the carrier group is implemented by a cylinder, and its piston rod is connected with one end of the carrier group to drive the carrier group. When the carrier group includes a carrier When the tool and the carrier seat are connected, the piston rod is connected with one end of the carrier seat. It can also achieve the effect of driving the movement of the carrier group.

Embodiment 3

[0067] Others are the same as those described in Embodiment 1, except that the label printer is arranged above the carrier group, and the dial tongue is also correspondingly arranged above the carrier group, so that the label is correspondingly If it is attached to the top of the material instead of the bottom, then the second label scanning sensor is correspondingly arranged above the starting end of the moving stroke of the carrier group, and the pressure roller is also arranged below the carrier group 2. Limit the material from below. This technical solution can also achieve the same effect as in Embodiment 1, and we can choose according to our needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com