A kind of tapping equipment for automobile safety belt frame

A seat belt frame, automobile technology, applied in the direction of metal processing equipment, tangent device, manufacturing tools, etc., can solve the problems of tapping, assembly work inconvenient, unable to ensure the car seat belt frame, etc., to achieve simple structure, convenient implementation, convenient Measured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

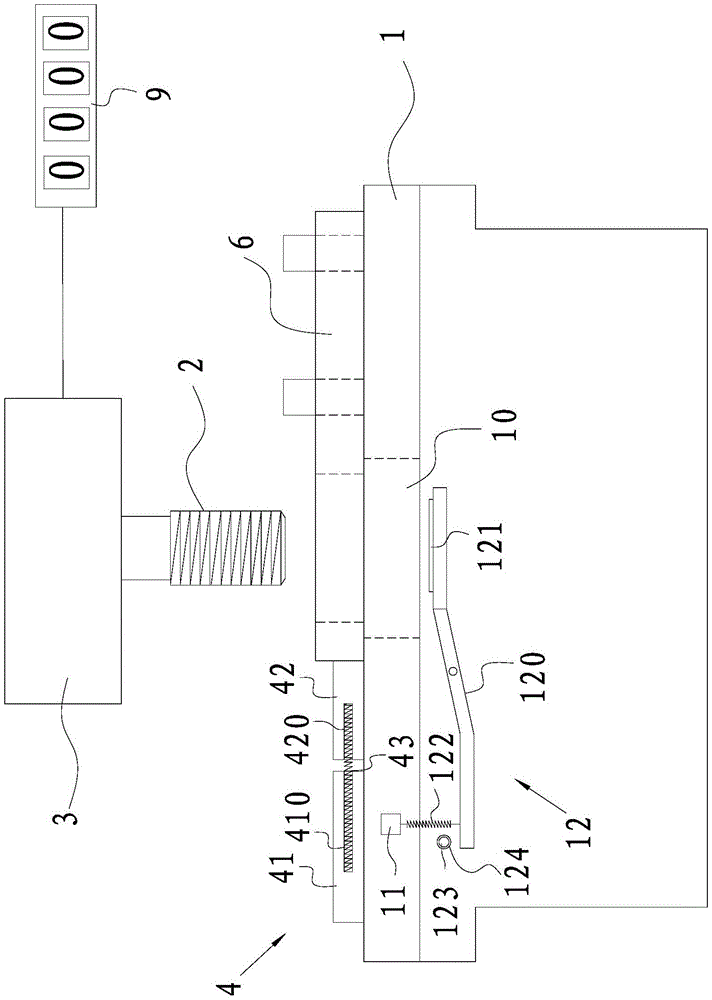

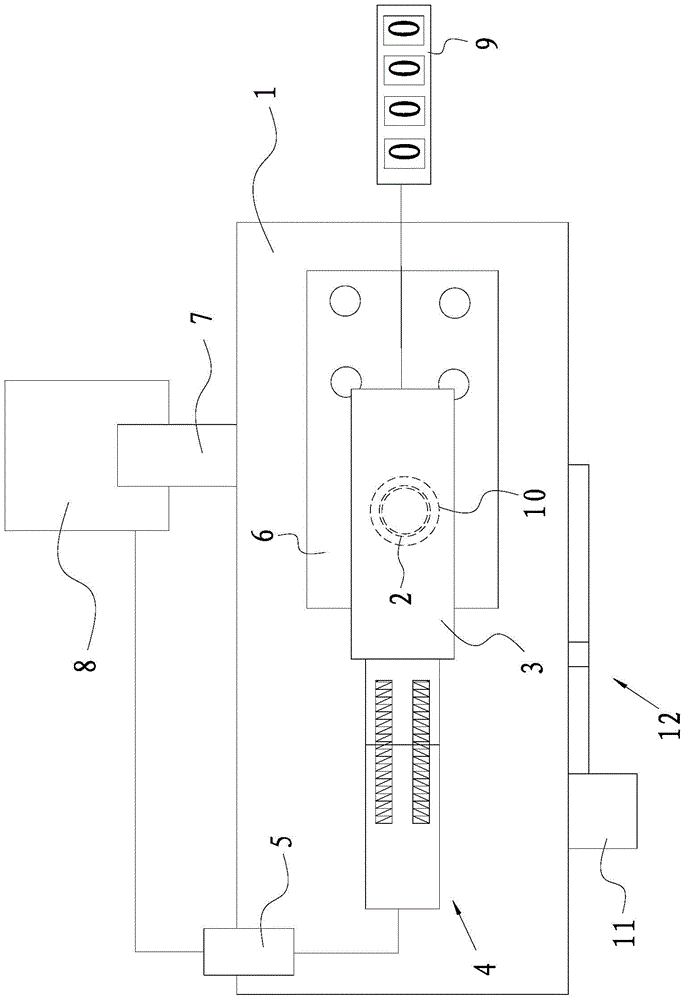

[0021] Such as figure 1 and figure 2 As shown, according to the tapping device of the automobile safety belt frame of this embodiment, it includes a positioning seat 1 with an avoidance hole 10, a screw tap 2 located above the positioning seat 1, and is used to drive the screw tap 2 to rotate and move up and down relative to the positioning seat 1 The drive mechanism 3, the contact switch 4 arranged on the positioning seat 1, the contactor 5 connected with the contact switch 4 by a line, the telescopic rod 7 that can extend into the car seat belt frame 6 on the right side of the positioning seat 1, can Receive the information of the contactor 5 and use it to control the telescopic movement control mechanism 8 of the telescopic rod 7, the counter 9 connected with the control mechanism 8 through the line, and the counter 9 located under the avoidance hole 10 that can contact the tap 2 and feed back the information to the control mechanism 8 The limiter 12 inside.

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com