Automobile door liquid leakage hole manufacture method

A technology for leak holes and doors, which can be used in doors, vehicle parts, transportation and packaging, etc., and can solve problems such as increased automobile manufacturing costs and waste of human and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

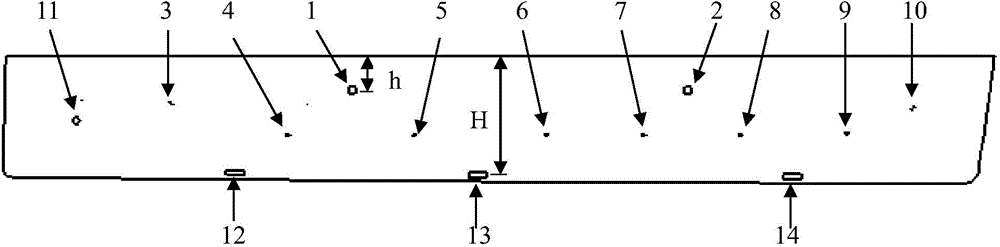

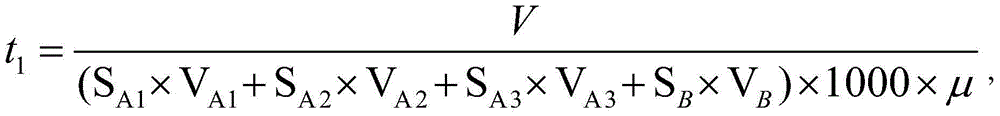

[0075] This embodiment provides a method for manufacturing a leak hole in a car door, the method comprising:

[0076] Step 101: Divide the volume of liquid in the cavity of the inner panel of the vehicle door and the outer panel of the vehicle door into multiple sub-volumes, and the liquid in each sub-volume includes an upper liquid surface and a lower liquid surface.

[0077] Step 102, obtain the distance from the center of the mounting hole of the guard plate of the car door, the center of the mounting hole of the door frame bar of the car door, the center of the mounting hole of the buffer block of the car door, and the center of the leaking hole of the car door to the upper liquid level of each sub-volume of liquid vertical distance.

[0078] Step 103 , obtaining the area of the installation hole of the guard plate of the vehicle door, the installation hole of the door frame strip of the vehicle door and the installation hole of the buffer block of the vehicle door.

[...

Embodiment 2

[0086] This embodiment provides a method for manufacturing a leak hole in a car door, the method comprising:

[0087] Step 201: According to the CATIA surface design, simulate the volume of the liquid in the cavity of the inner panel of the car door and the outer panel of the car door, and make the XY plane tangent to the highest liquid level shift downwards by a predetermined distance sequentially along the Z-axis direction, The volume of the liquid in the cavity of the inner panel of the vehicle door and the outer panel of the vehicle door is divided into multiple sub-volumes, and the liquid in each sub-volume includes an upper liquid surface and a lower liquid surface.

[0088] Wherein, the volume of the liquid in the cavity of the inner panel of the above-mentioned car door and the outer panel of the car door will vary according to different models. The maximum volume of liquid that can be contained in the cavities of the panels and outer panels of the doors.

[0089] Thr...

Embodiment 3

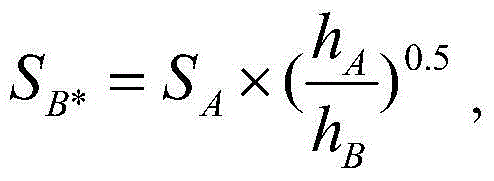

[0124] This embodiment provides a method for manufacturing a leak hole in a car door. Step 301, step 302, step 303, step 304, step 308, step 309 and step 310 included in the method are respectively the same as those in embodiment 2. Step 201, step 202, step 203, step 204, step 207, step 208 and step 209 are the same, and the reference relationship therein is also adjusted accordingly. In particular, this embodiment provides different steps 305 , 306 and 307 . Specifically, step 305, step 306 and step 307 are respectively:

[0125] Step 305, according to multiple sub-volumes, in step 302, from the center of the mounting hole of the guard plate of the car door, the center of the door frame bar mounting hole of the car door, the center of the buffer block mounting hole of the car door and the center of the liquid leakage hole of the car door to each sub-volume The vertical distance of the upper liquid surface of the liquid, and the area of the guard plate mounting hole of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com