Working boat automatic storing device

An automatic retractable and working boat technology, which is applied in the direction of the device used to guide the ship to the water surface, the control equipment responding to the situation, etc., can solve the problems of the failure of the working boat to retract, affect the operation command of the mother ship, and stay on the slide for a short time. , to achieve the effect of convenient and reliable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, the present invention is further described:

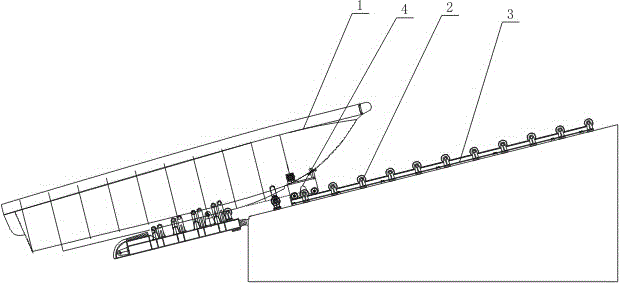

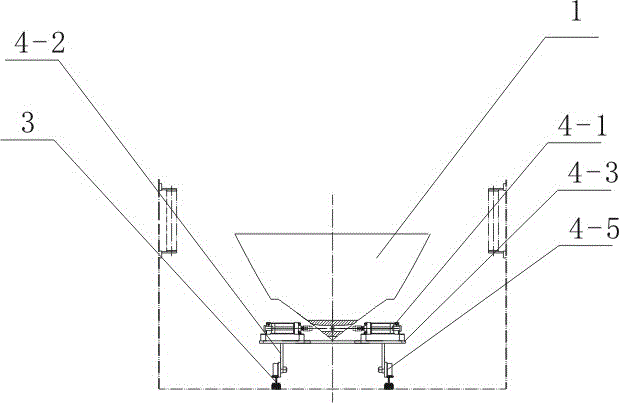

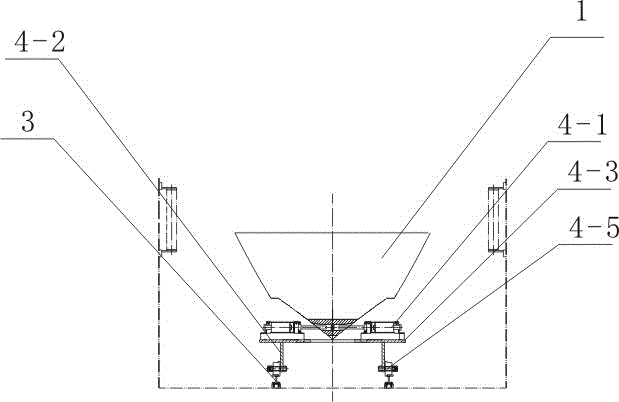

[0020] Such as Figure 1 to Figure 4 The working boat automatic retracting device shown includes a working boat 1 with a horn hole at the lower end of the bow. The working boat 1 can rely on its own power to rush to the mother ship chute along the slideway 2. The mother ship chute is equipped with a track 3. There is a trolley 4 on the track; wherein the axis of the track 3 and the slideway 2 are on the same straight line, and the surface height of the trolley 4 on the track 3 is the same as that of the slideway 2 .

[0021] The trolley 4 includes a spring cylinder 4-1, a trolley roller bracket 4-2, a trolley panel 4-3, a mooring ring 4-4, a roller 4-5, a bracket 4-6, an in-position sensor 4-7, Bracket bracket 4-8; the spring cylinder 4-1 is arranged on both sides of the bow axis of the working boat 1 through bracket welding or bolted connection, and the roller 4-5 is welded on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com