Knife feeding device used for L-type packing machine

A packaging machine and knife device technology, used in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of continuous film cutting, easy deformation by heating, easy damage to the knife tip, etc., and achieve the effect of improving stability and improving firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

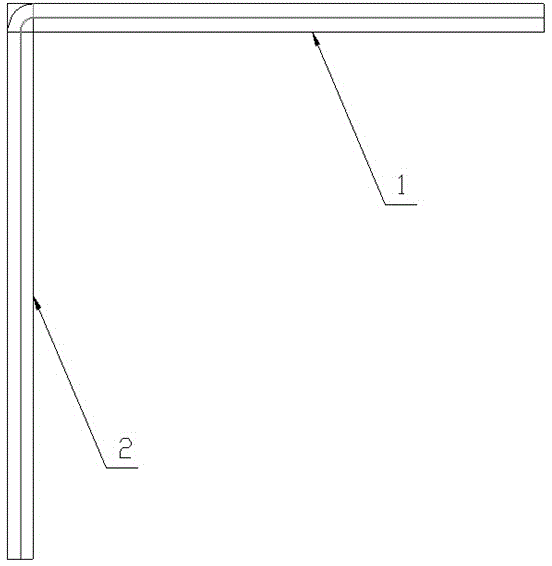

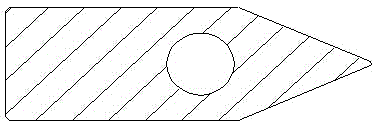

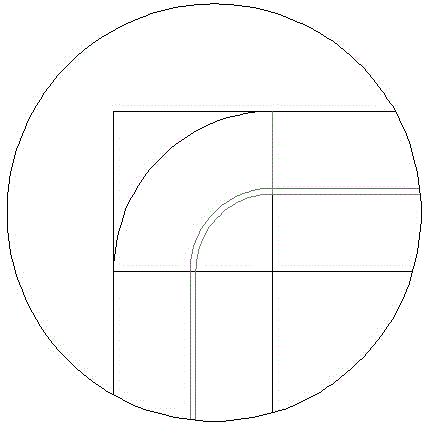

[0017] refer to Figure 1-Figure 3 As shown, a knife upper device for an L-shaped packaging machine includes a horizontal knife 1 and a vertical knife 2, and the horizontal knife 1 and the vertical knife 2 are spliced together.

[0018] Further, both the horizontal knife 1 and the vertical knife 2 are made of alloy steel, and are connected by circular arc knife edges.

[0019] Preferably, the horizontal knife 1 and the vertical knife 2 are provided with lifting bolts, a knife body mounting block and a mica plate.

[0020] Further, the lifting bolts, the cutter body mounting block and the mica plate are all installed on the upper beam of the sealing cutter.

[0021] Preferably, a waist hole is designed on the cutter body mounting block and the mica plate pad, because during the sealing and cutting process, the high temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com