Cubic pottery decorative wall structure and its installation method

An installation method, the technology of square pottery, applied in the direction of building structure, covering/lining, construction, etc., can solve the problems affecting the overall appearance, achieve the effect of improving the overall appearance, improving the acoustic performance, and quick and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

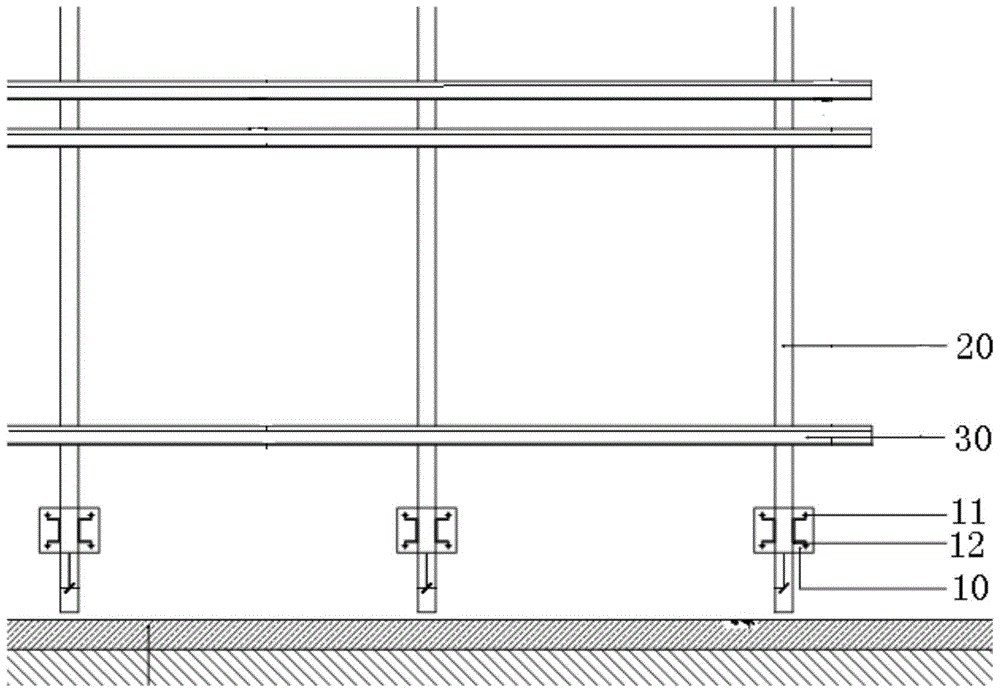

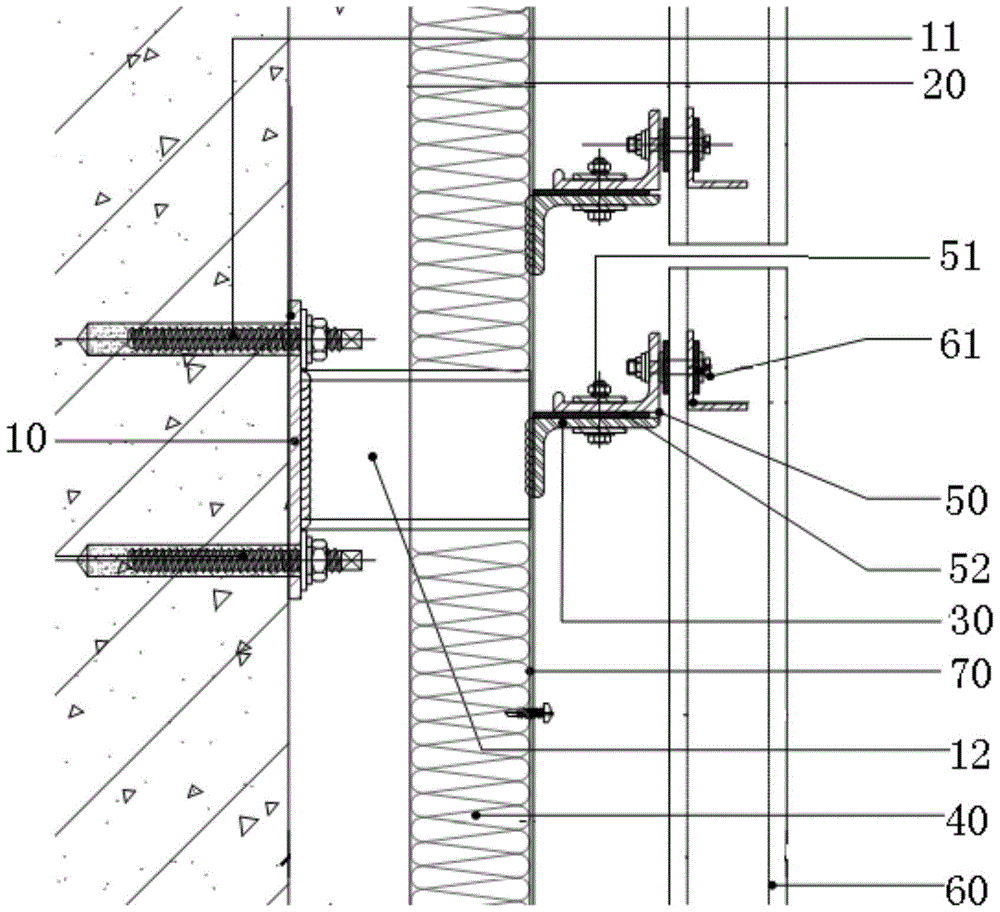

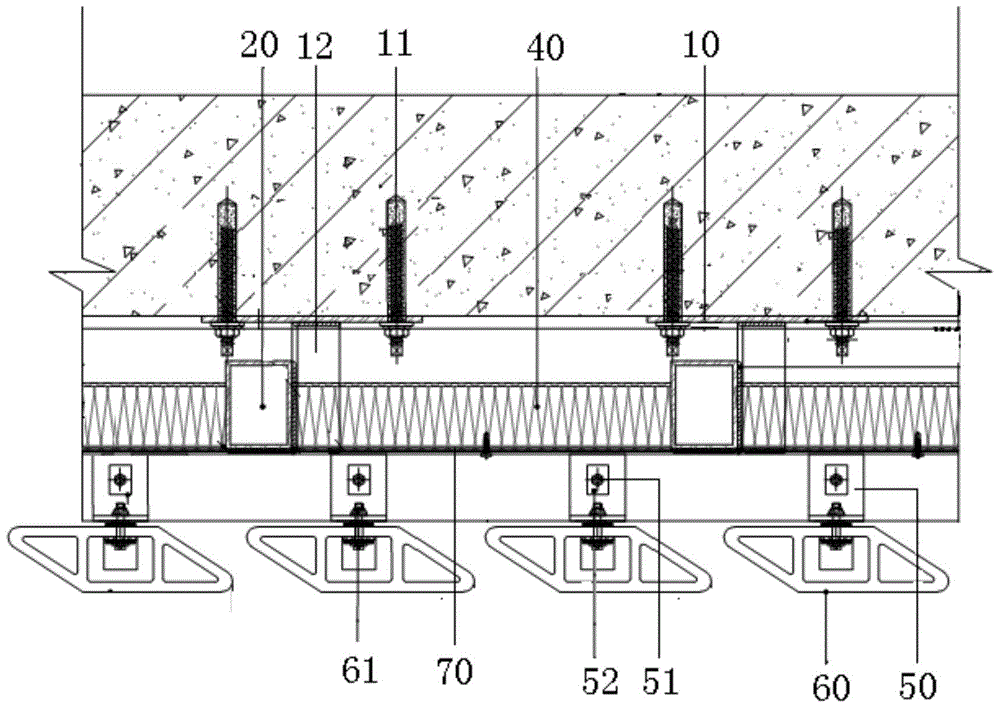

[0030] The cubic pottery decorative wall structure includes: rear embedded parts 10, chemical anchor bolts 11, adapters 12, vertical main keel 20, horizontal auxiliary keel 30, glass wool 40, pendant 50, cubic pottery 60, back bolt 61, Bolt 51 , shielding plate 70 and rubber pad 52 .

[0031] The rear embedded part 10 is made of a steel plate of 200*150*8mm, and is fixed at a predetermined position on the surface of the building by using an M12*140 chemical anchor bolt 11 .

[0032] Adapter 12 selects 8# channel steel for use. After the rear embedded part 10 is fixed, 8# channel steel is fully welded on the rear embedded part 10 as the adapter 12 fixed with the vertical main keel 20 . The vertical main keel 20 is made of hot-dip galvanized 80*60*5 square tube, and is fully welded with the adapter 12. The vertical main keel is provided with e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com