A kind of modification method of recycled concrete aggregate and its concrete composition and application

A technology of concrete composition and recycled concrete, applied in the field of recycled concrete, can solve problems affecting the mechanical strength of concrete, concrete broken and collapsed, and limit the application of recycled concrete aggregates, so as to achieve the effect of resource utilization and improvement of performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

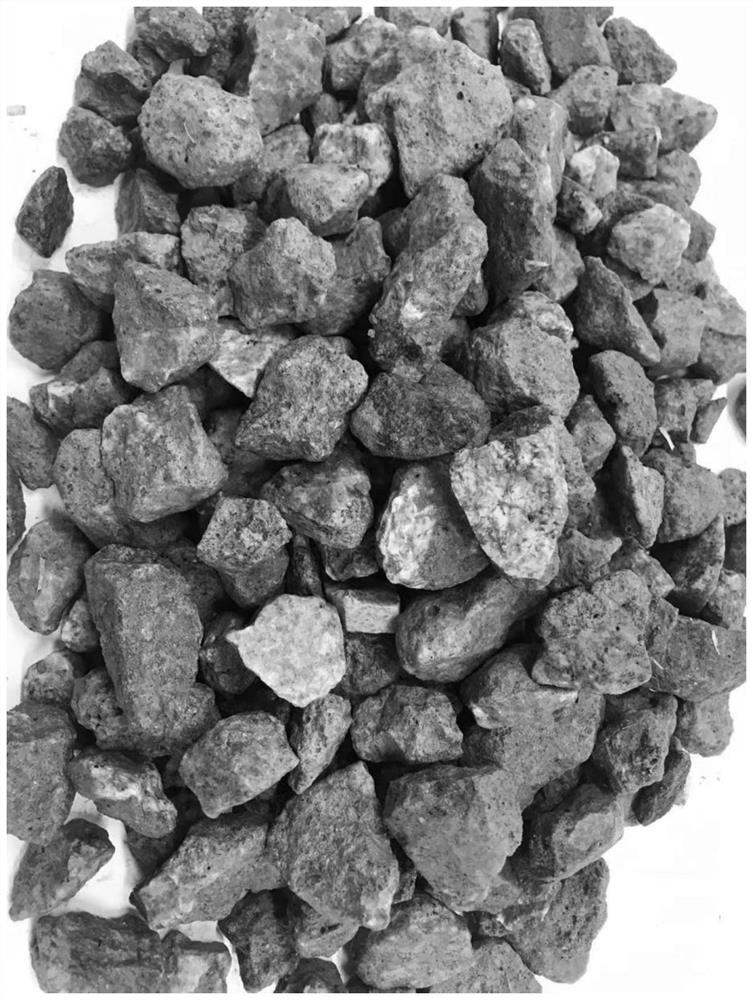

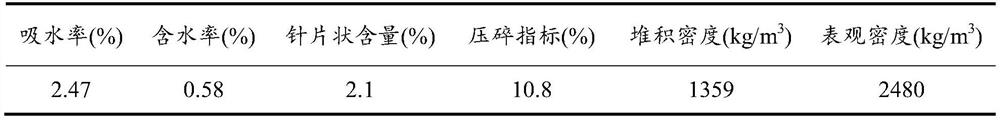

Image

Examples

Embodiment 1

[0043] A method for modifying recycled concrete aggregates, comprising the steps of:

[0044] (1) Immerse the regenerated concrete aggregate in a calcium chloride solution with a mass concentration of 35%, and make the calcium chloride solution completely submerge the regenerated concrete aggregate, so as to be fully impregnated, filter and separate after dipping for 6 hours, and wait for The recycled concrete aggregate can not drop the liquid, and the modified aggregate can be obtained once for use.

[0045] (2) in the high-pressure reaction tank, add the ammoniacal liquor 450ml that the mass concentration is 25%, and in this high-pressure reaction tank, the ammoniacal liquor is provided above the support screen plate, the described primary modified aggregate of 550g is placed on the support screen plate, then Close the sealing cover of the reaction tank, heat the water bath of the high-pressure reaction tank to 55 ° C, and keep the temperature for 3 hours, so as to use the a...

Embodiment 2

[0048] A method for modifying recycled concrete aggregates, comprising the steps of:

[0049] (1) Immerse the recycled concrete aggregate in a calcium chloride solution with a mass concentration of 32%, and make the calcium chloride solution completely submerge the recycled concrete aggregate, so as to be fully immersed, and filter and separate after immersion for 7.5 hours. The recycled concrete aggregate can not drop the liquid, and the modified aggregate can be obtained once for use.

[0050] (2) in the high-pressure reaction tank, add the ammoniacal liquor 450ml that the mass concentration is 25%, and in this high-pressure reaction tank, the ammoniacal liquor is provided above the support screen plate, the described primary modified aggregate of 550g is placed on the support screen plate, then Close the sealing cover of the reaction tank, heat the water bath of the high-pressure reaction tank to 45 ° C, and keep the temperature for 4 hours, so that the primary modified agg...

Embodiment 3

[0053] A method for modifying recycled concrete aggregates, comprising the steps of:

[0054] (1) Immerse the recycled concrete aggregate in a calcium chloride solution with a mass concentration of 30%, and make the calcium chloride solution completely submerge the recycled concrete aggregate, so as to be fully immersed, filter and separate after 8 hours of immersion, and wait for The recycled concrete aggregate can not drop the liquid, and the modified aggregate can be obtained once for use.

[0055] (2) adding the ammoniacal liquor 450ml that the mass concentration is 20% in the high-pressure reaction tank, and in the high-pressure reaction tank, above the ammoniacal liquor, a support screen is arranged, the described primary modified aggregate of 550g is placed on the support screen, and then Close the sealing cover of the reaction tank, heat the water bath of the high-pressure reaction tank to 60 ° C, and keep the temperature for 3 hours, so that the primary modified aggre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com