Anti-colliding and anti-grinding stall lock

A technology of rolling cars and parking locks, which is applied in the field of parking locks, and can solve problems such as scrapping, deformation, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

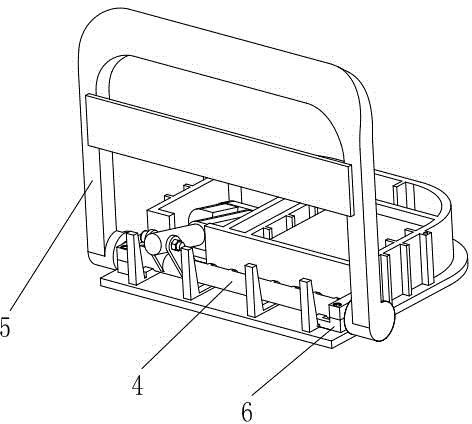

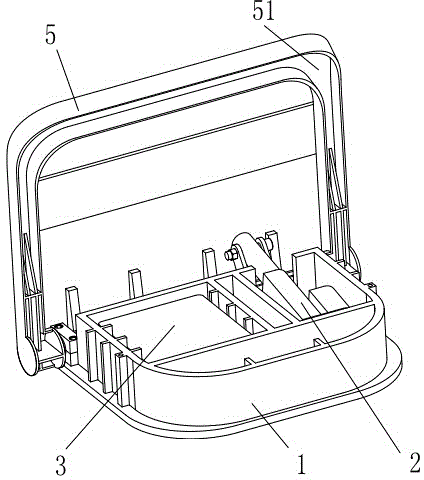

[0030] Such as figure 1 , figure 2 As shown, the anti-collision and anti-rolling parking lock of the present invention includes a base 1, and a motor 2 is fixedly arranged in the base 1, and the output shaft of the motor 2 is fixedly connected to the rotating shaft 4 through the connector 43;

[0031] The front side of the base 1 is fixedly provided with a rotating shaft seat 6, which is pivotally connected to the rotating shaft 4; the two ends of the rotating shaft 4 are fixedly connected to the rocker arm 5; the motor 2 is powered by the battery 3, and the motor 2 pushes the rotating shaft 4 through its output shaft. Make the rotating shaft 4 rotate relative to the rotating shaft seat 6, so as to realize the turning over of the rocker arm 5 relative to the base 1;

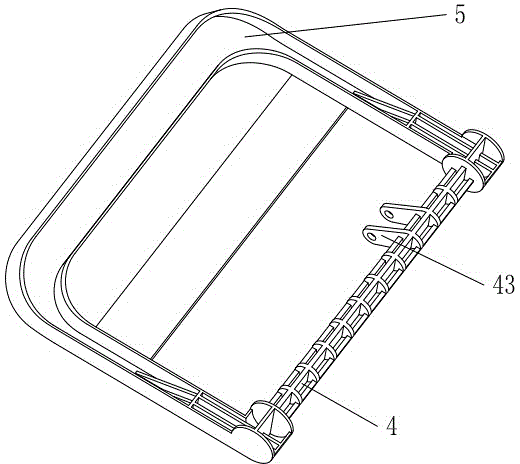

[0032] The section of the rotating shaft 4 is circular; the rotating shaft 4 is longitudinally distributed with a plurality of grooves to form a hollow semicircular shaft;

[0033] Such as image 3 , Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com