Manual and motorized dual-input speed reducer

A kind of manual motor, reducer technology, applied in the direction of transmission box, mechanical equipment, transmission device, etc., can solve the problem of molten metal can only be cooled in the road, and the motor drive is difficult to achieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

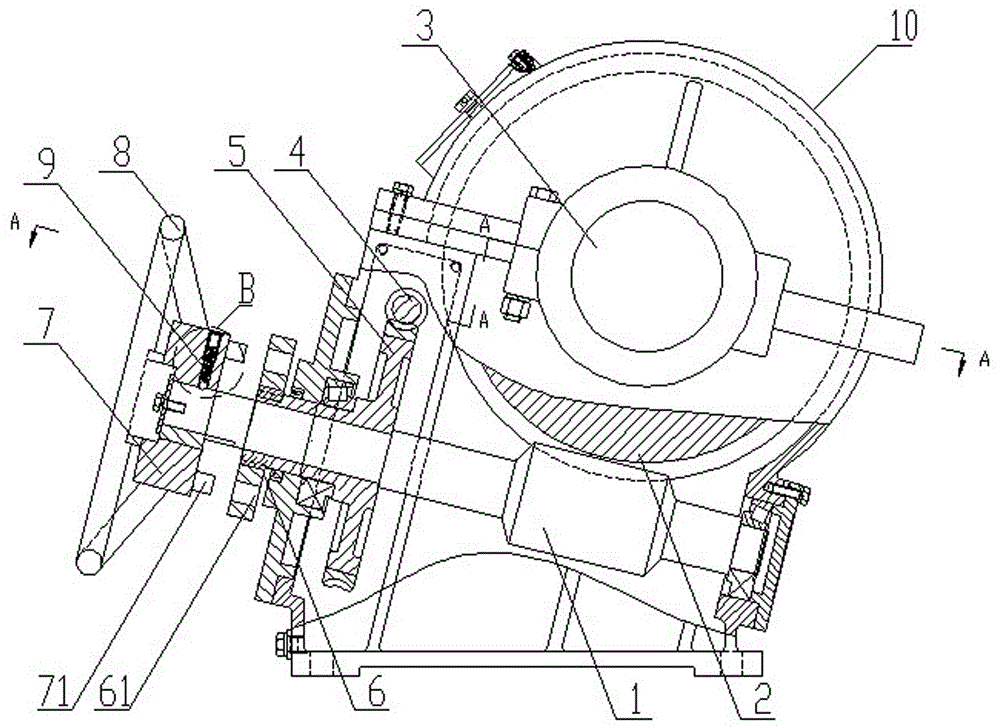

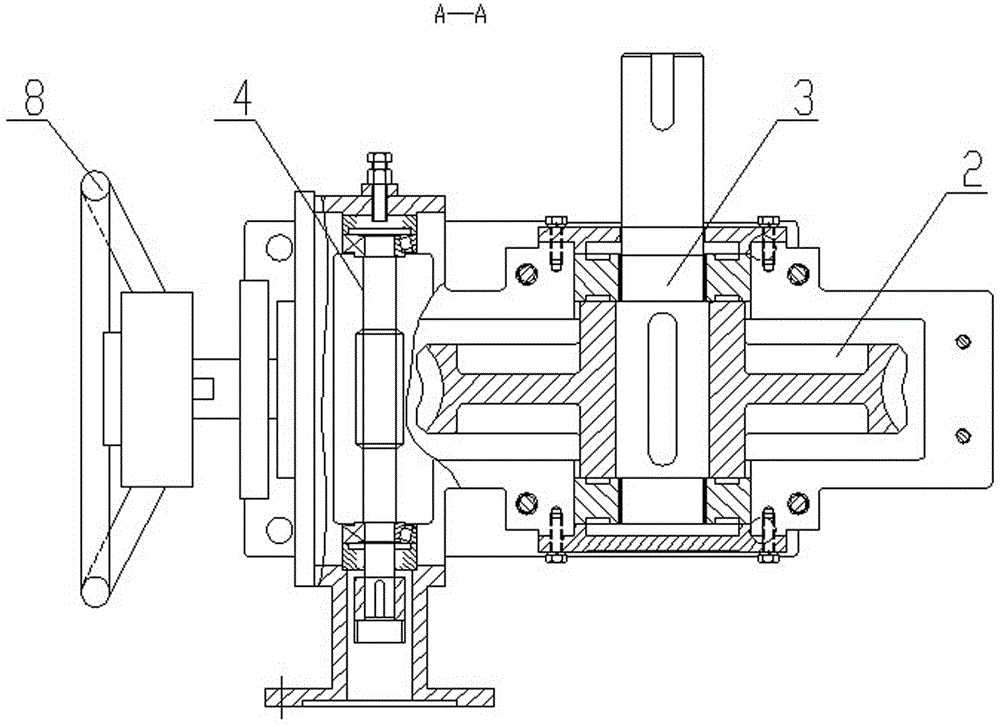

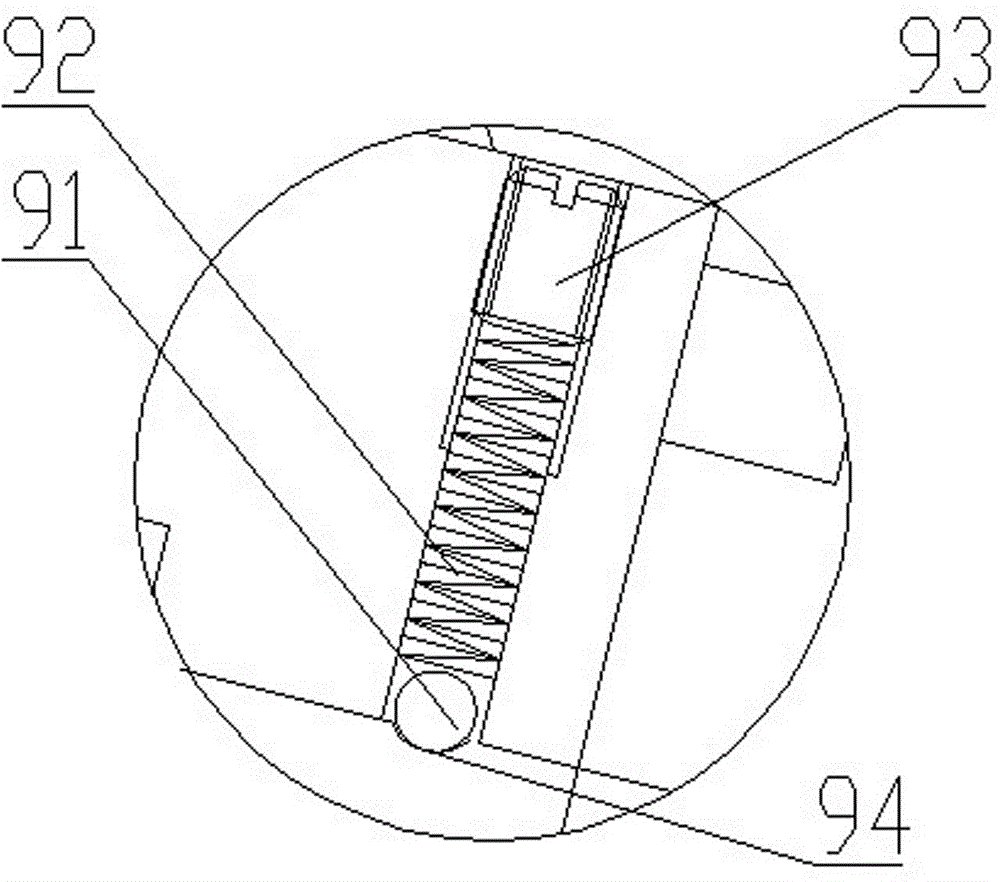

[0015] As shown in the figure, a manual motorized double-input reducer includes a housing 10, and the housing 10 is provided with a worm gear mechanism and an output shaft 3. The worm is connected to the housing 10 through a bearing, and the worm gear and the worm are engaged. Transmission; the upper part of the worm 1 in the housing 10 is connected with a small worm 4 through a bearing, the output end of the small worm 4 is connected to the input motor, and the worm 1 is fixedly sleeved with a small worm wheel 5, and the small worm 4 and the small worm wheel 5 for meshing transmission; one side of the small worm wheel 5 is a sleeve-type extension end, and the sleeve-type extension end extends out of the housing, and the sleeve-type extension end and the small worm wheel 5 are One-piece molding, the sleeve-type extension end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com