A universal header coupling device for a combine harvester

A combine harvester, a general-purpose technology, applied to harvesters, applications, cutters, etc., can solve problems such as time-consuming and labor-intensive, unfavorable harvesting operations competing for farming time, troublesome replacement of headers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

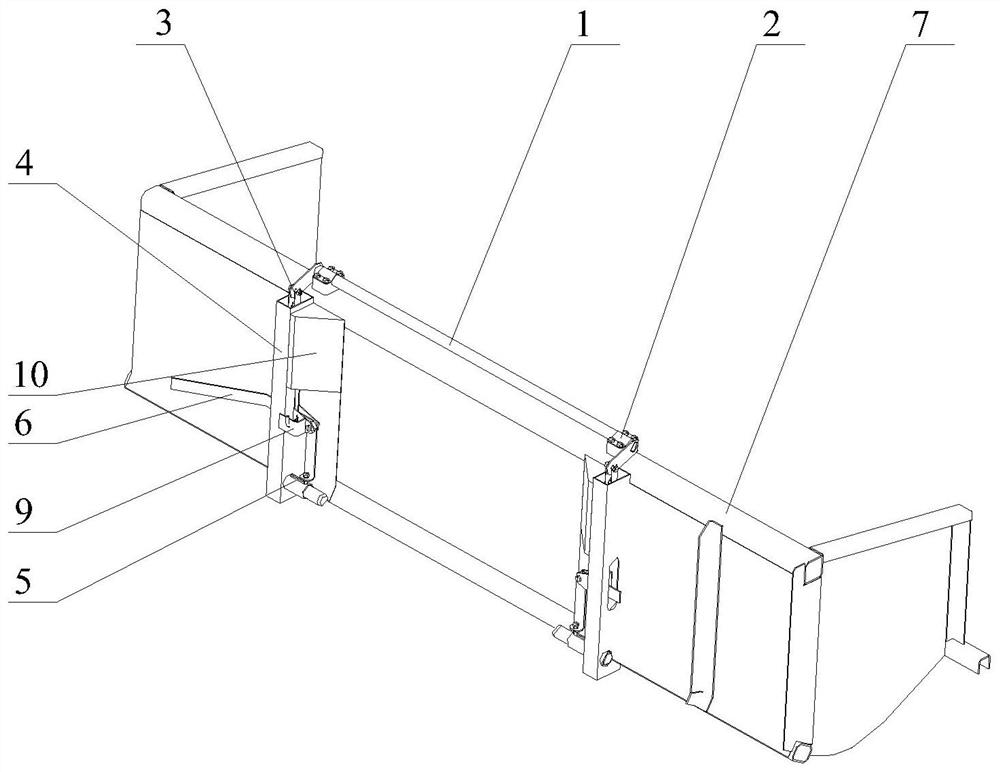

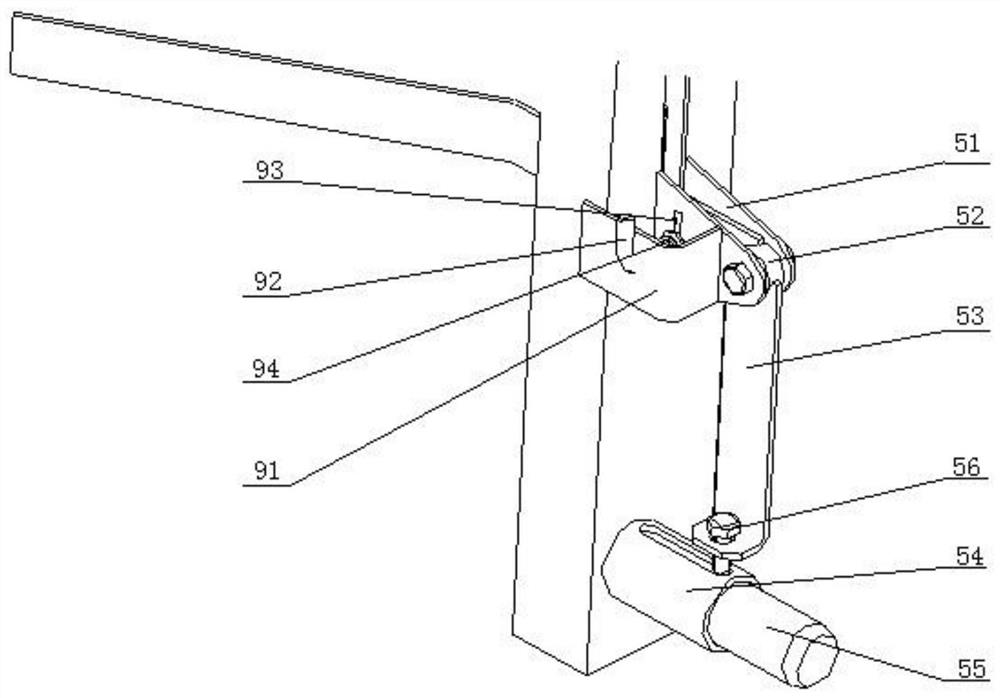

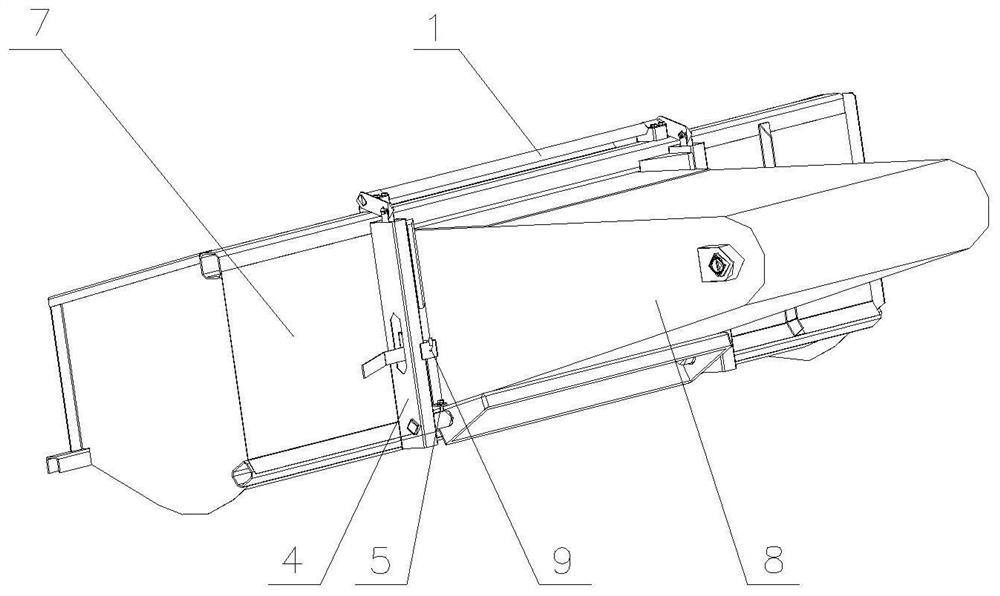

[0032] Embodiment: A general-purpose header coupling device for a combine harvester, comprising a header part of the combine harvester, a conveying trough part and a coupling mechanism connecting the two parts. The hooking mechanism includes two hooking parts and a rotating shaft connecting the two hooking parts. A guiding part is arranged between the two hooking parts, and a limiting part is arranged at the connecting position of the header part and the conveying trough part.

[0033] The composition and connection relationship of each part are described in detail.

[0034] 1. Mounting part:

[0035] The two articulated parts are symmetrical as a whole, and both include a fixed seat, a connecting rod assembly, a support tube, a linkage locking assembly and a handle respectively. The difference is that the handle of one of the hooking parts is longer than the handle of the other side, and a set of latch components is provided for the handle.

[0036] The two fixing bases ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com