Assembly type curtain wall bay-window frame hanging structure

A connection structure and assembly technology, applied in the direction of frame fixing, walls, windows/doors, etc., can solve the problems of labor waste, great harm of smoke and dust pollution, difficulty in controlling welding precision on site, etc., and achieve the effect of firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described below in conjunction with accompanying drawing.

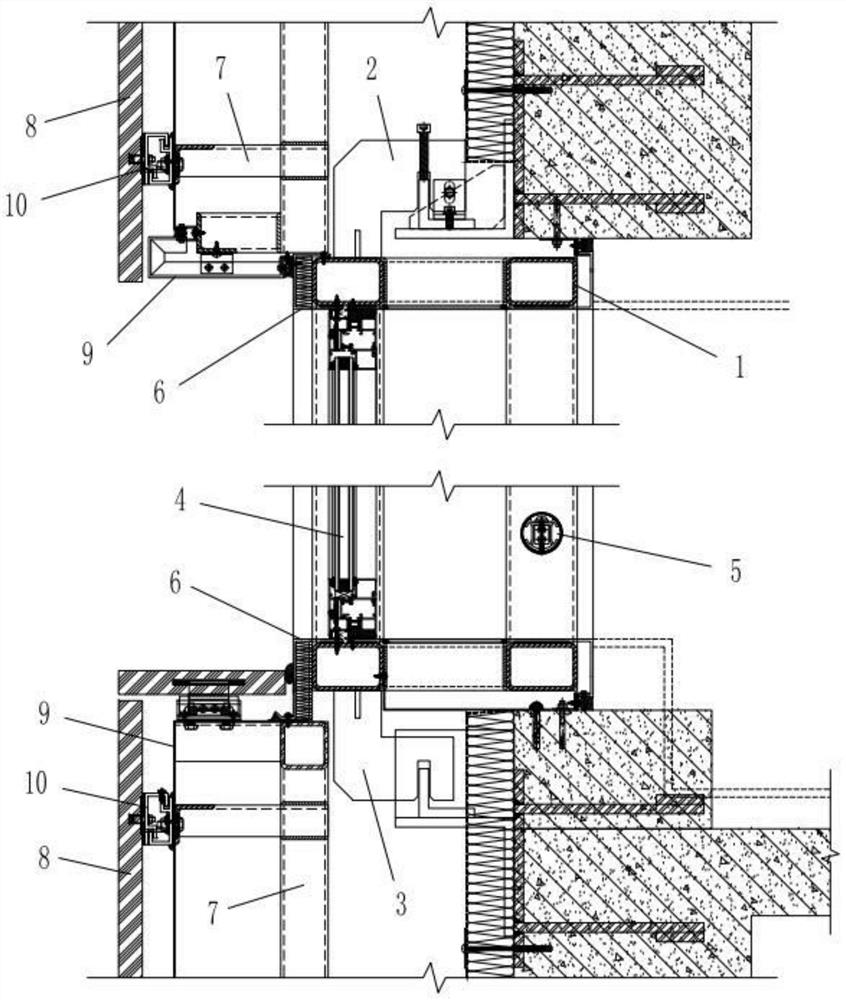

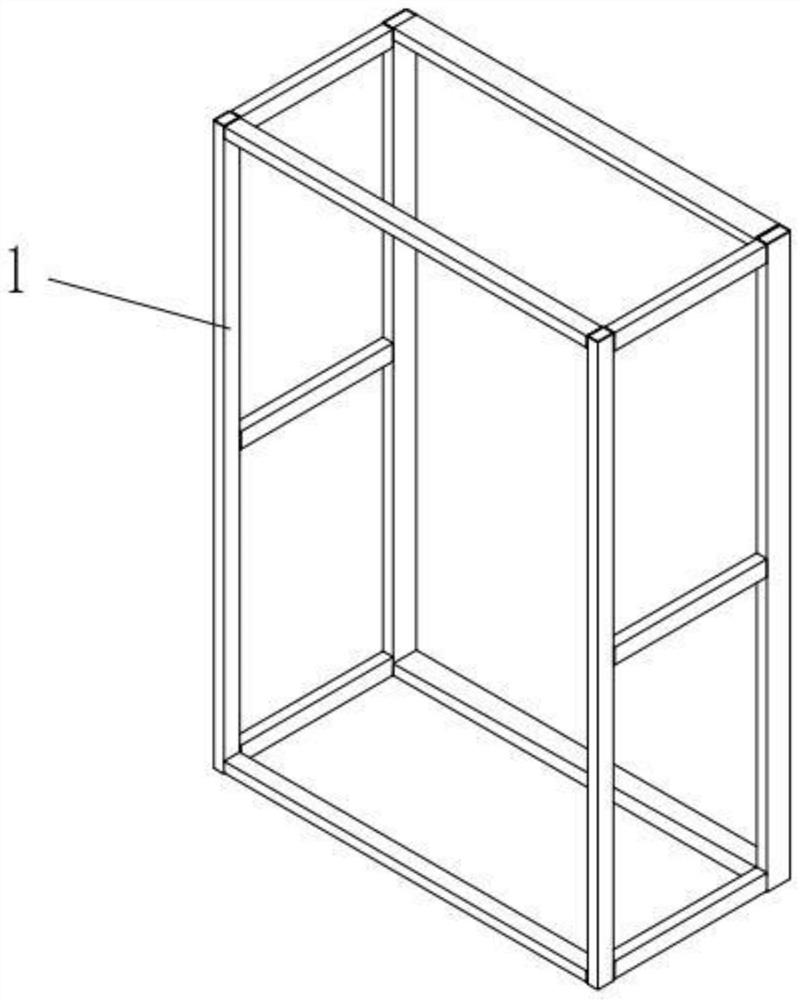

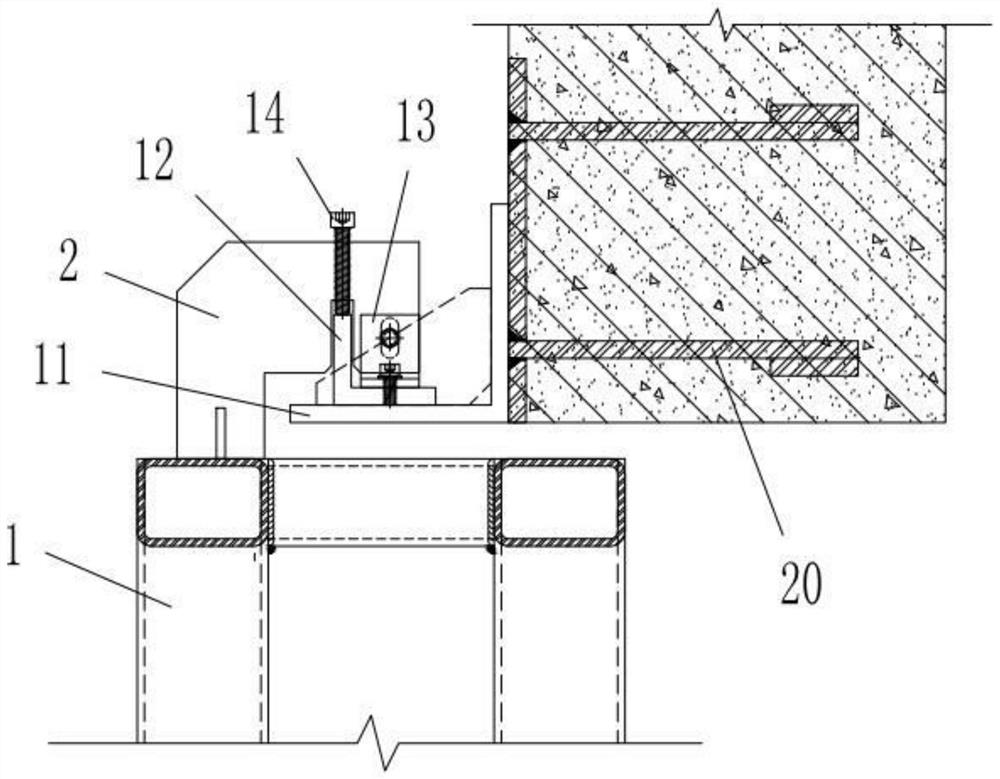

[0021] as attached figure 1 , 2 As shown, an assembled curtain wall bay window frame hooking structure according to the present invention includes a bay window frame 1, the bay window frame 1 is a rectangular frame structure, the bay window frame 1 is located at the window opening of the main body of the building, and the bay window frame 1. The window opening of the main body of the building is convex; the outdoor side of the bay window frame 1 is equipped with a bay window glass 4 through a glass frame structure, and the interior side of the bay window frame 1 is provided with an inner guardrail 5. On the frame part of the bay window frame 1 A wrapped aluminum plate 6 is provided.

[0022] The outdoor side of the main body of the building is provided with a curtain wall joist 7 and a curtain wall stone 8, the curtain wall joist 7 is fixedly installed on the outdoor side of the build...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com