Optical fiber cable and manufacturing method of optical fiber cable

A fiber optic cable and fiber optic cable technology, which is applied in the field of fiber optic cable and fiber optic cable manufacturing, can solve the problems of weak connection ability of the protective sleeve, damage of the fiber optic cable, and difficulty in erecting the staff.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

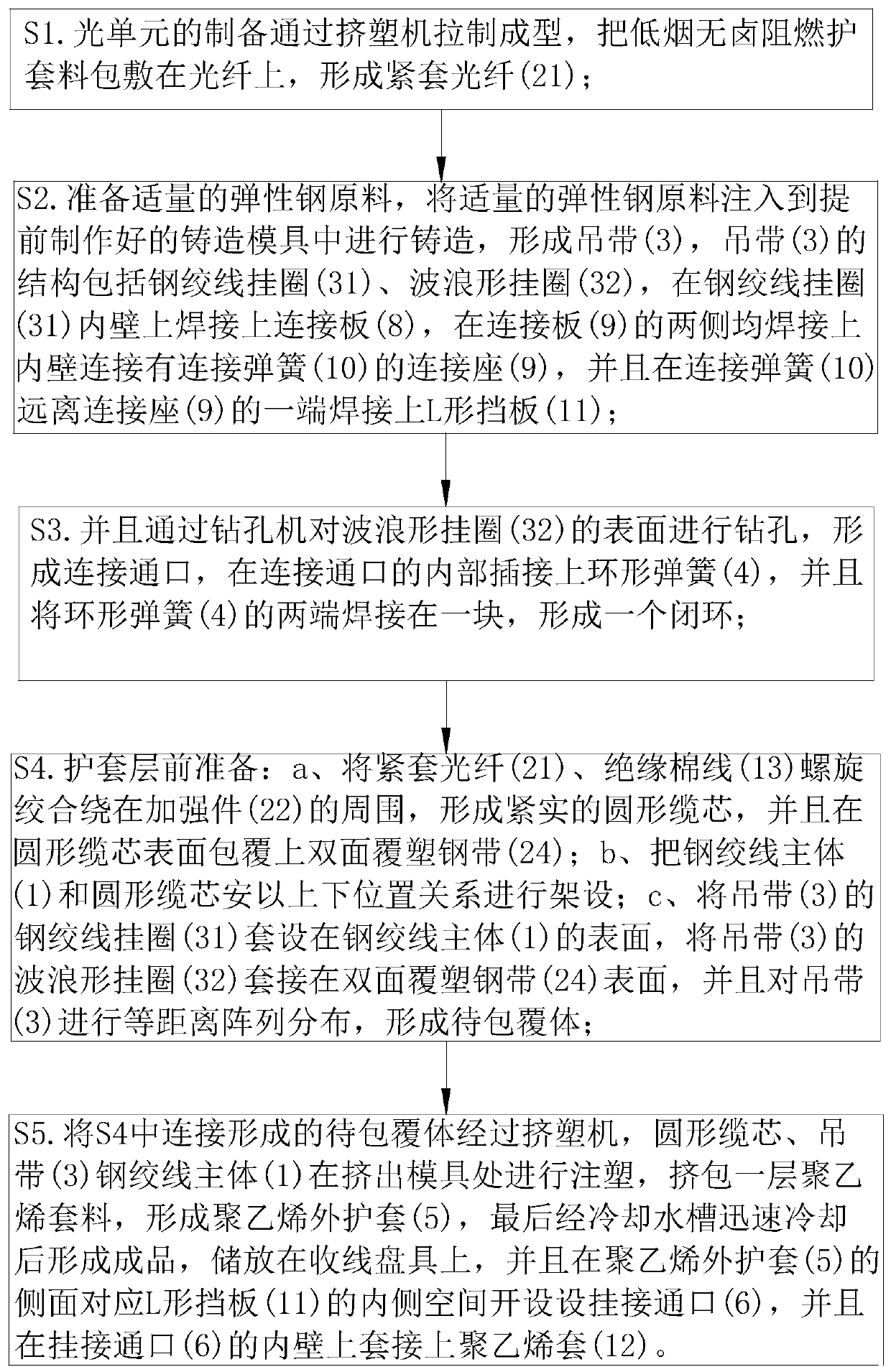

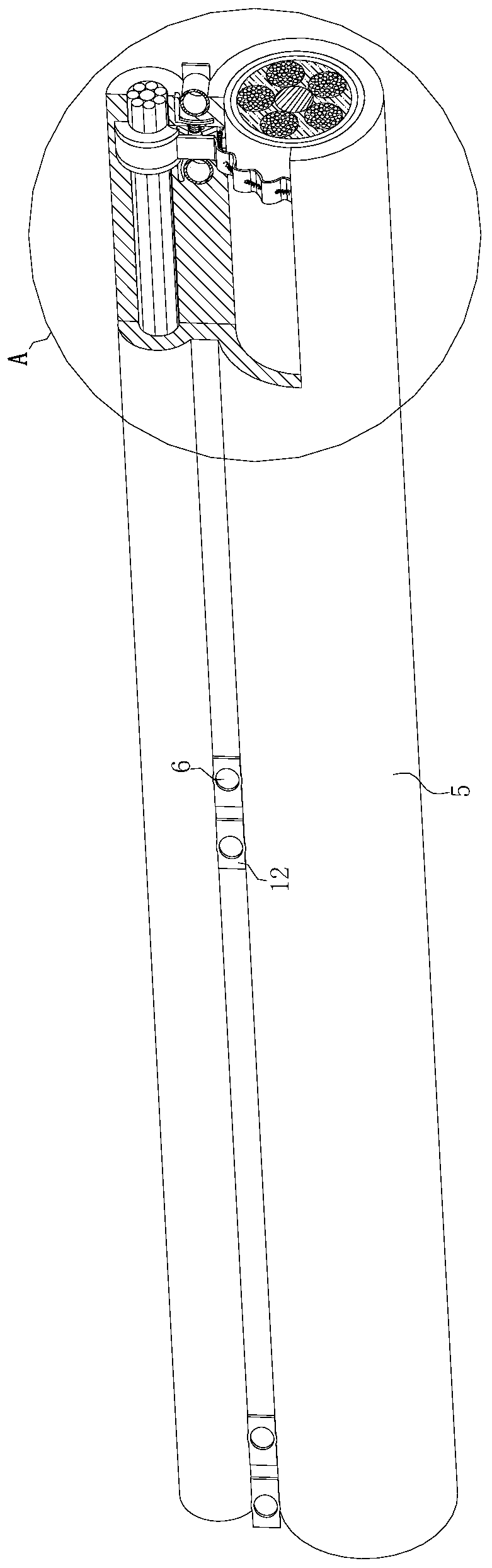

Method used

Image

Examples

Embodiment approach

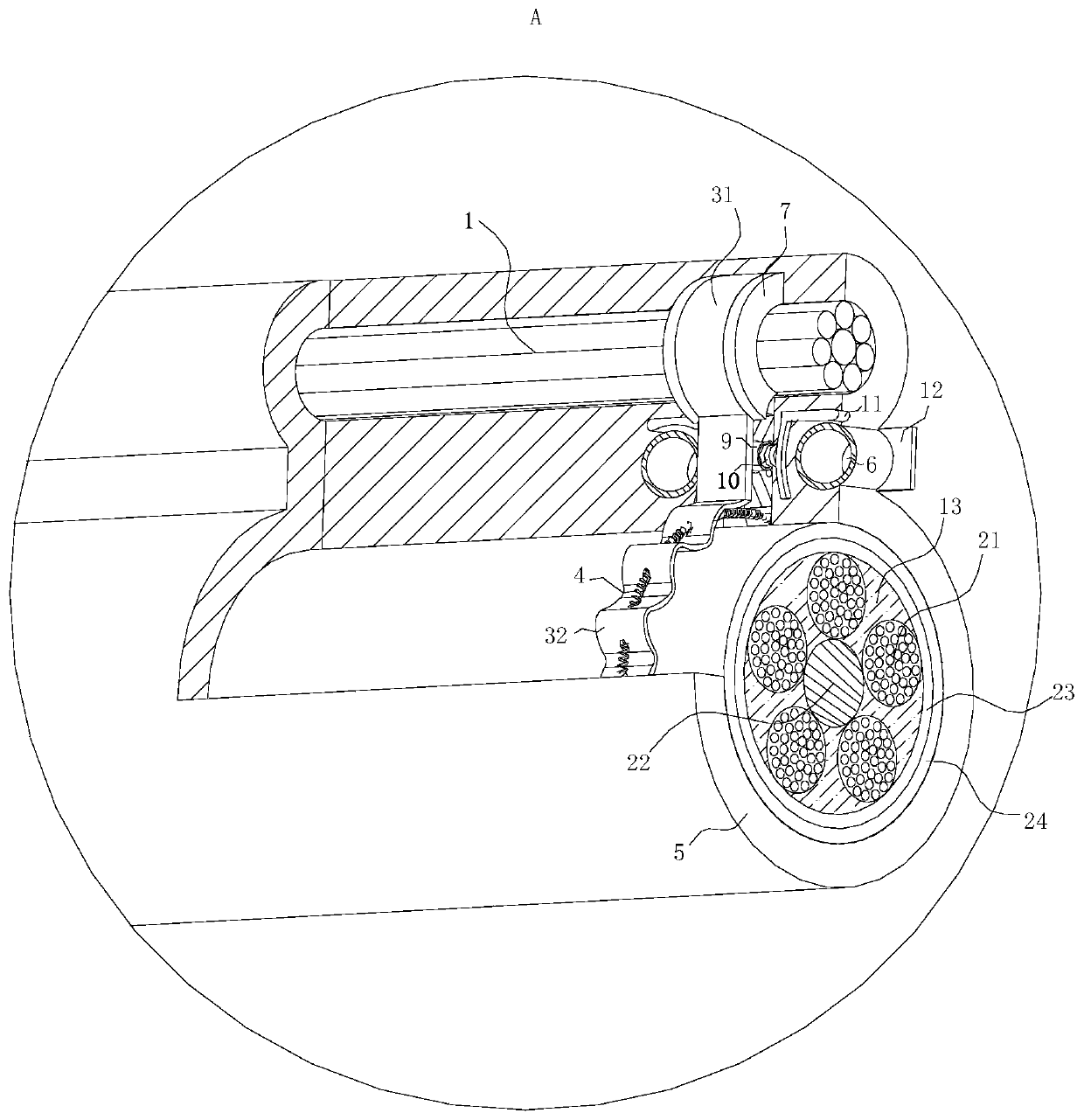

[0033] As an embodiment of the present invention, a connecting plate 8 is fixedly connected to the inner wall of the steel strand hanging ring 31 ; both sides of the connecting plate 8 are fixedly connected with a connecting seat 9 ; A connection spring 10 is fixedly connected on the upper part; when working, when the hooking rope is attached to the hooking port 6, when the wind and rain are hit and the optical fiber cable is shaking, the hooking rope is connected to the inner side of the hooking port 6. The force is large, and it is easy to produce a squeezing force on the side of the sling 3, which adds a larger driving force to the sling 3 and affects the stability of the sling 3. By setting the connecting seat 9 and the connecting spring 10, the side of the sling 3 can be increased. The supporting point, when the side receives the extrusion force, the connecting spring 10 will elastically expand and contract, which can buffer the extrusion force, reduce the extrusion of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com