Battery cap welding machine

A welding machine and battery cover technology, applied in welding equipment, non-electric welding equipment, laser welding equipment, etc., can solve the problems of welding reliability, low welding precision, low efficiency, and cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further description will be made below in conjunction with drawings and embodiments.

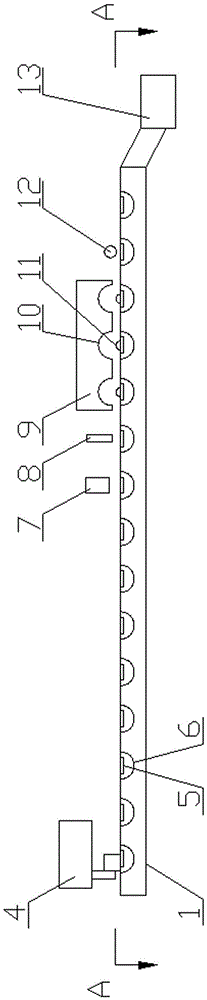

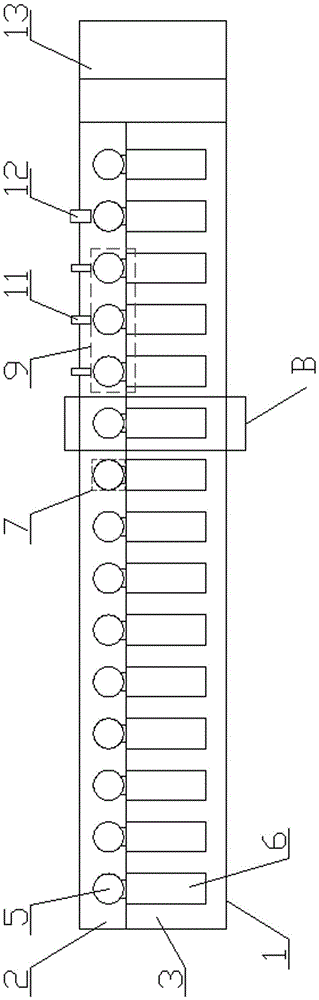

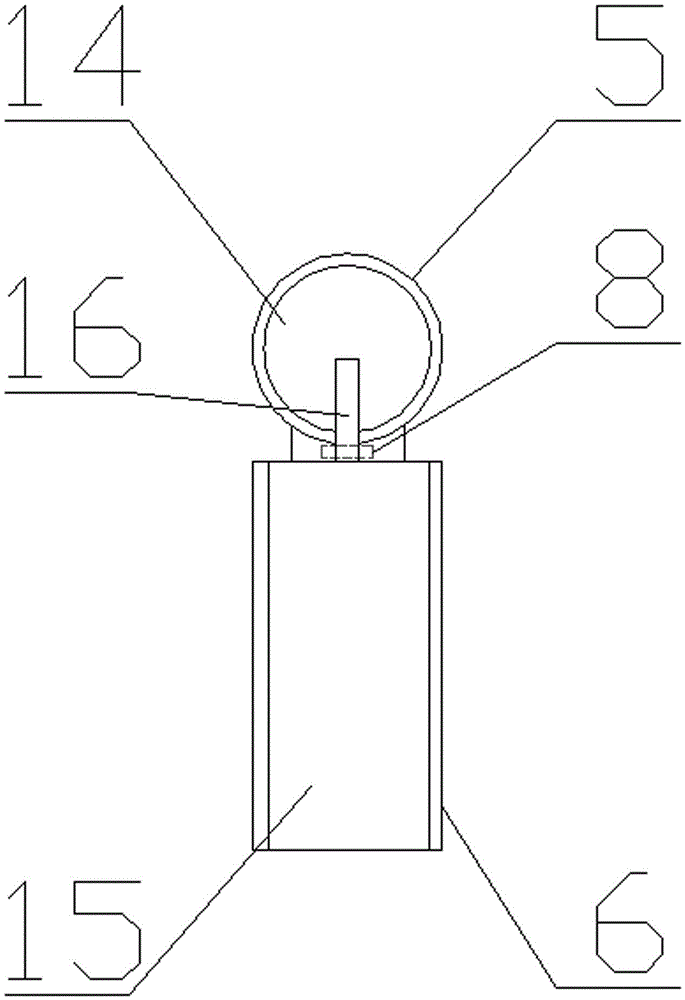

[0017] Figure 1-2 As shown, a battery cap welding machine includes a welding track 1, a cap placement track 2, a battery placement track 3, a cap vibrating screen 4, a welding head 7, a cap turning head 8, a cap closing head 9, and a battery bonding groove 10. Cap pressing cylinder 11, push unloading head 12 and waste collection tank 13 The welding track 1 is driven by a motor to rotate circularly. The welding track 1 is provided with a cap placement track 2 and a battery placement track 3. The battery placement track is set on the cap placement track On one side, a plurality of cap placement holes 5 are sequentially arranged at intervals on the cap placement track 2, the cap vibrating screen 4 corresponds to the cap placement 14 connected to the cap placement hole 5 at one end of the cap placement track 2, and the battery placement track 3 is provided with a plurality of correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com