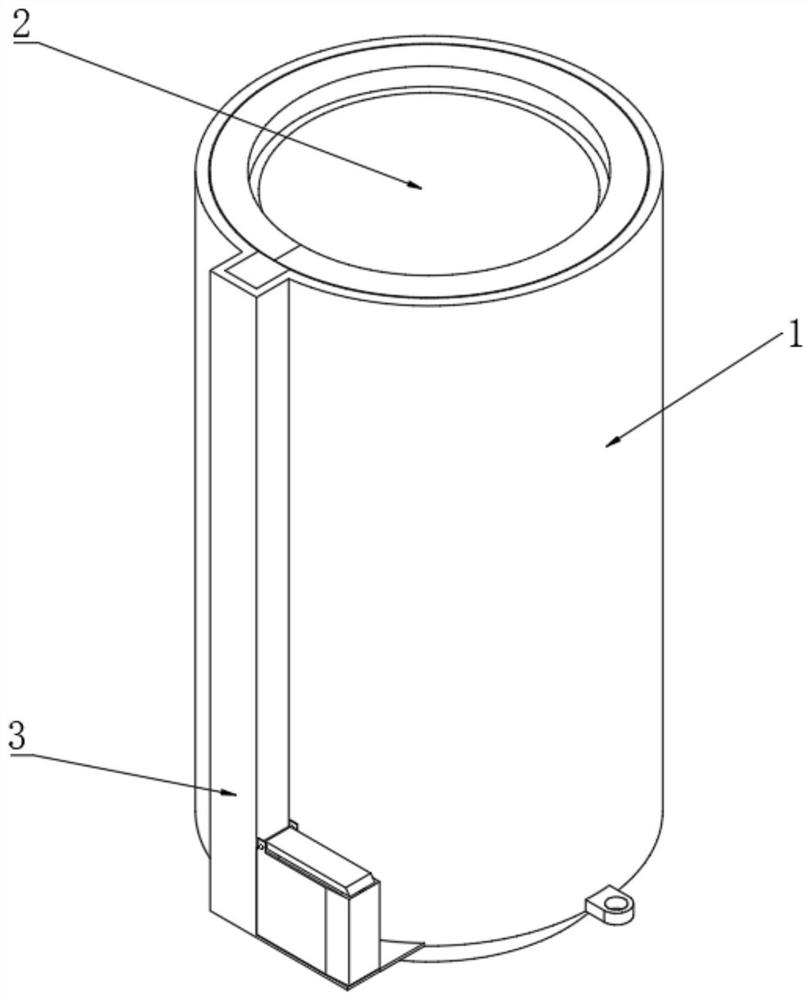

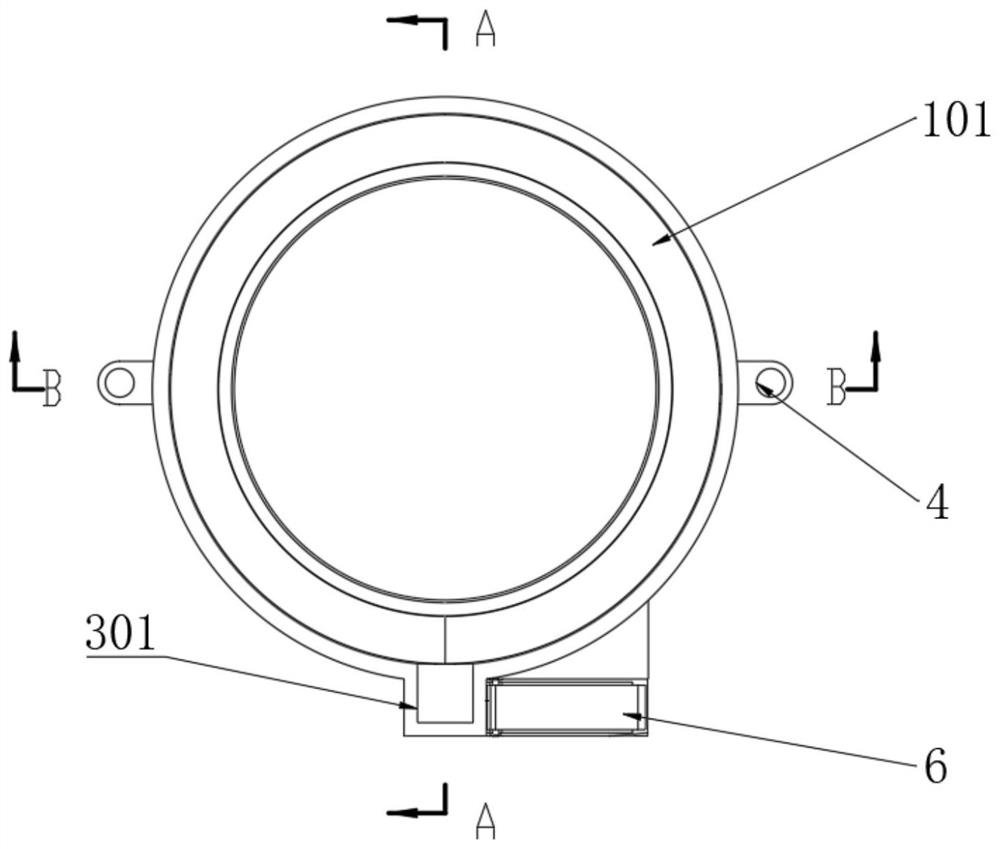

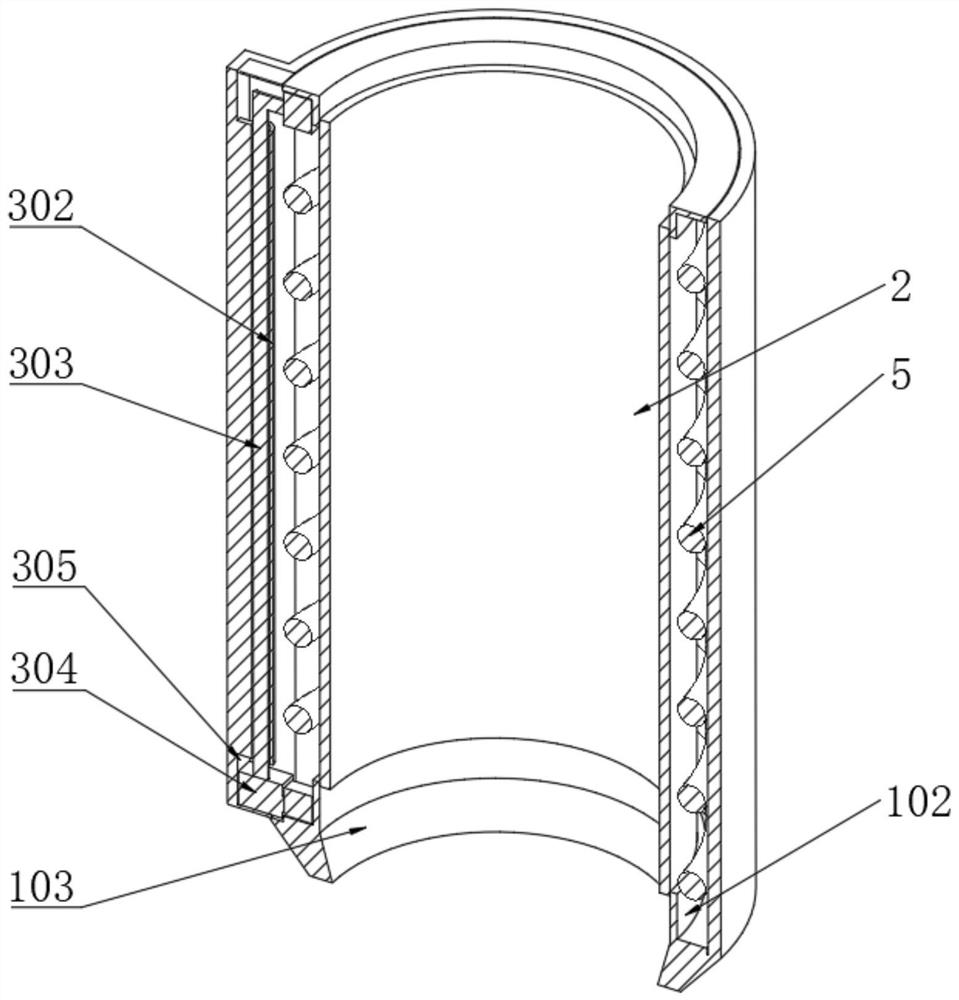

Novel pipeline corrosion and scale inhibition method and device

A technology for corrosion and scale inhibition and pipelines, applied in chemical instruments and methods, descaling and water softening, special treatment targets, etc., can solve problems such as the inability to meet the needs of factory circulating water treatment, and achieve good corrosion and scale inhibition performance. , Strengthen the strength, inhibit the effect of excessive reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Adopt the present invention to be applied to the pipeline circulating cooling water of a thermal power plant:

[0056] The circulating cooling water pipeline of a certain factory can clean out 28kg of scale inhibitors in one month. Let the factory install the corrosion and scale inhibition device according to the instructions of this application, and add 11kg of the corrosion and scale inhibition material prepared by this application to the circulating cooling water of the pipeline. Connect the device to the power supply and turn on the device, the nano-soft ferrite in the nano-corrosion and scale-inhibiting material performs a helical movement in the helical forward magnetic field generated by the device, and follows the water flow through the entire pipeline. The PESA and special CQDs in the corrosion and scale inhibition materials soften the scale inhibition texture, which is destroyed by the moving nano soft magnetic ferrite. After the installation of the device of...

Embodiment 2

[0060] Adopt the present invention to be applied to the pipeline circulating cooling water of a thermal power plant:

[0061] The circulating cooling water pipeline of a certain factory can clean out 36kg of scale inhibitors in one month. Let the factory install the corrosion and scale inhibition device according to the instructions of this application, and add 8kg of the corrosion and scale inhibition material prepared by this application to the circulating cooling water of the pipeline. Connect the device to the power supply and turn on the device, the nano-soft ferrite in the nano-corrosion and scale-inhibiting material performs a helical movement in the helical forward magnetic field generated by the device, and follows the water flow through the entire pipeline. The PESA and special CQDs in the corrosion and scale inhibition materials soften the scale inhibition texture, which is destroyed by the moving nano soft magnetic ferrite. After installing the device of the present...

Embodiment 3

[0065] Adopt the present invention to be applied to the pipeline circulating cooling water of a waste incineration power plant:

[0066] The circulating cooling water pipeline of a certain factory can clean out 33kg of scale inhibitors in one month. Let the factory install the corrosion and scale inhibition device according to the instructions of this application, and add 10kg of the corrosion and scale inhibition material prepared by this application to the circulating cooling water of the pipeline. Connect the device to the power supply and turn on the device, the nano-soft ferrite in the nano-corrosion and scale-inhibiting material performs a helical movement in the helical forward magnetic field generated by the device, and follows the water flow through the entire pipeline. The PESA and special CQDs in the corrosion and scale inhibition materials soften the scale inhibition texture, which is destroyed by the moving nano soft magnetic ferrite. After installing the device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com