Light reflection device for track inspection trolley

A track inspection vehicle and reflective device technology, applied in the direction of optical devices, measuring devices, transportation and packaging, etc., can solve the problems of aggravated deterioration of track conditions and increased track damage, and achieve small vibration displacement and meet precision requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

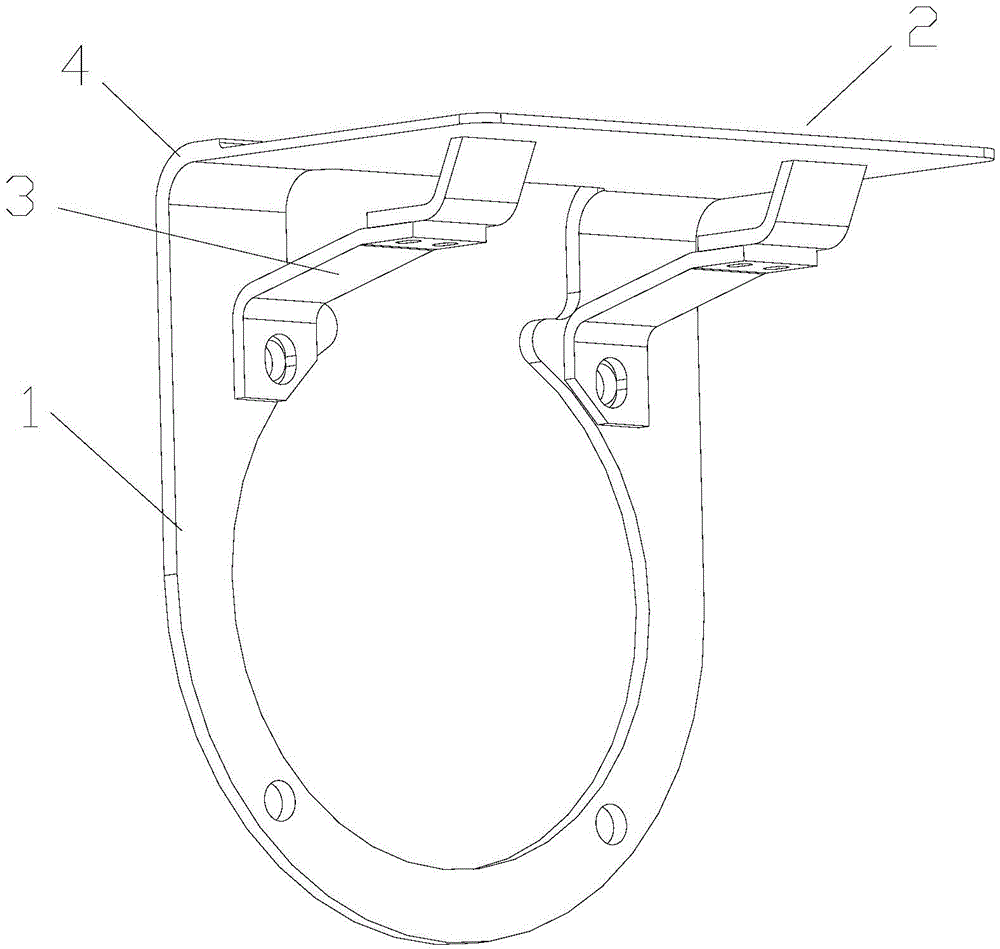

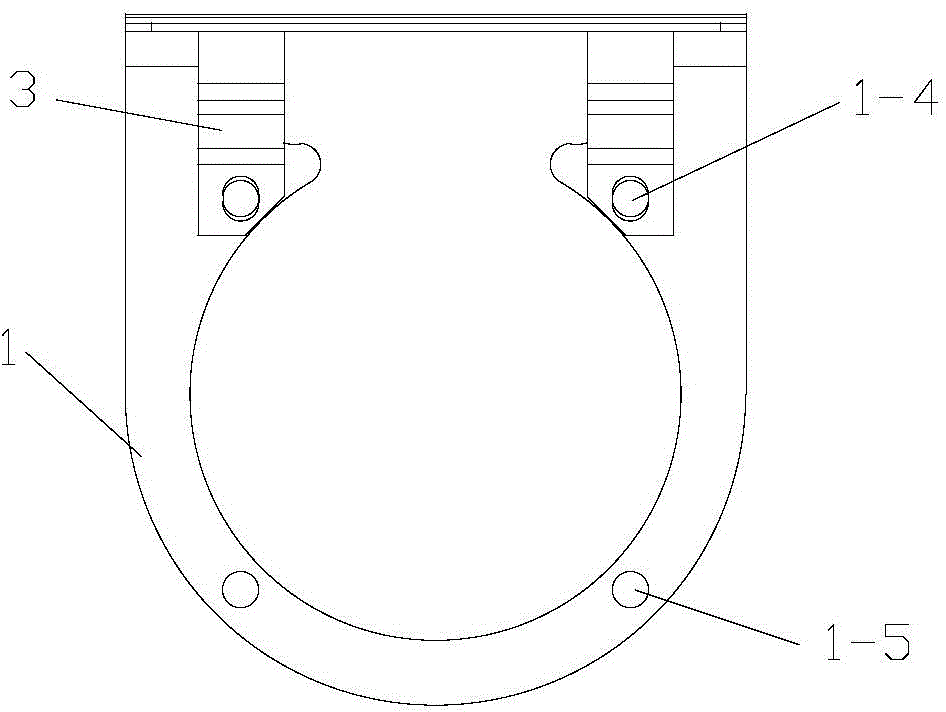

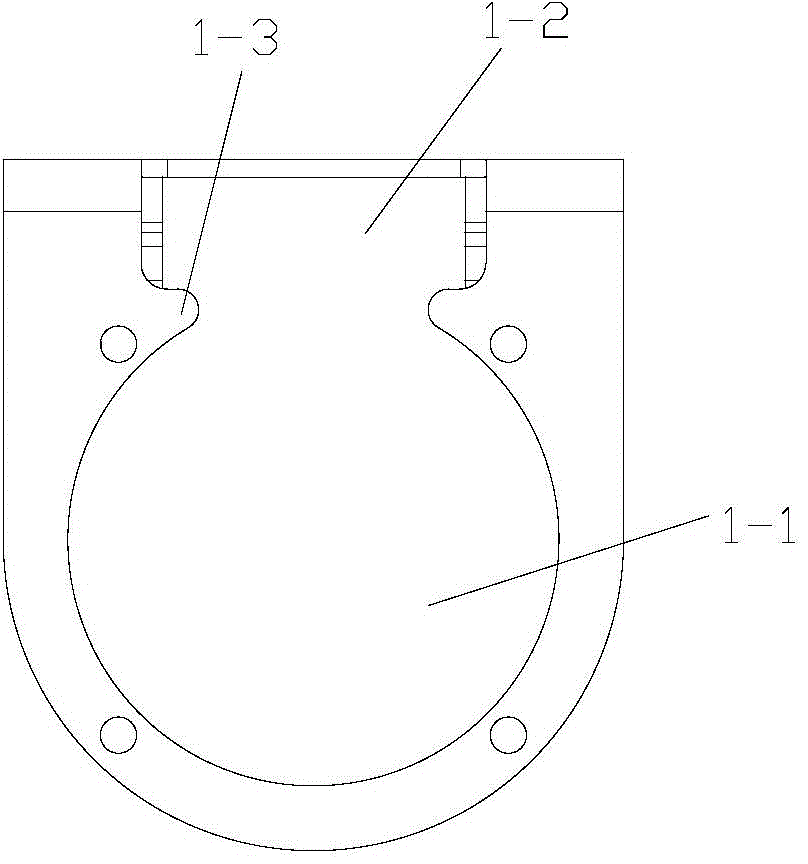

[0020] Such as Figure 1 to Figure 7 As shown, the reflective device for track inspection vehicles in this embodiment includes a base plate 1 fixed on the shaft end of the track inspection vehicle bogie, and the top of the base plate 1 extends away from the direction of the bogie Reflector 2, the reflector 2 is perpendicular to the base plate 1, and It is integrally formed with the base plate 1 ; one end of the support member 3 is fixedly connected to the side of the base plate 1 away from the bogie, and the other end of the support member 3 is fixedly connected to the bottom surface of the reflector 2 .

[0021] The support 3 includes a first member 3-1 and a second member 3-2. The first member 3-1 includes a first connection plate 3-11 fixedly connected to the upper part of the substrate 1. The first connection plate 3-11 is close to the reflector The end of the first folded plate 3-12 extends obliquely toward the reflective plate 2 in the direction away from the substrate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com