Detection method for quality of lithium battery pole piece

A quality inspection method and lithium battery technology, applied in the direction of measuring electrical variables, measuring devices, measuring resistance/reactance/impedance, etc., can solve the problem of inability to detect the uniformity of the coating on the surface of the pole piece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] The specific steps of the lithium battery pole piece quality detection method are as follows:

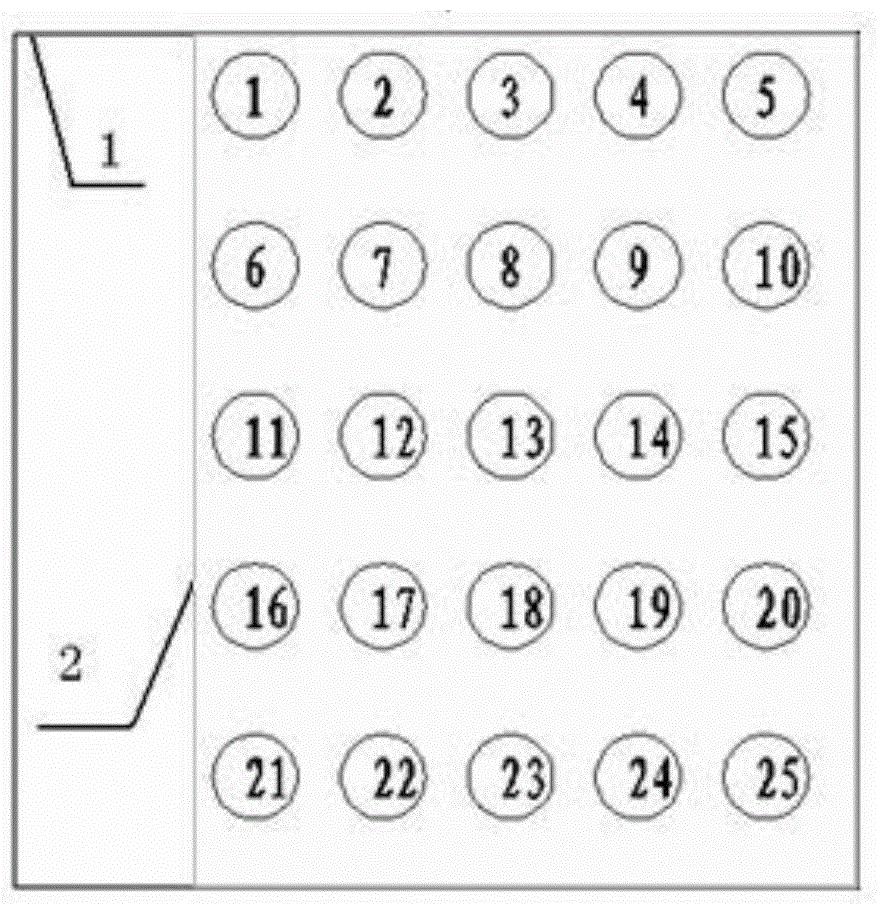

[0027] a) Take a pole piece containing the lug area and the coating area, and take points in the coating area according to the uniform distribution;

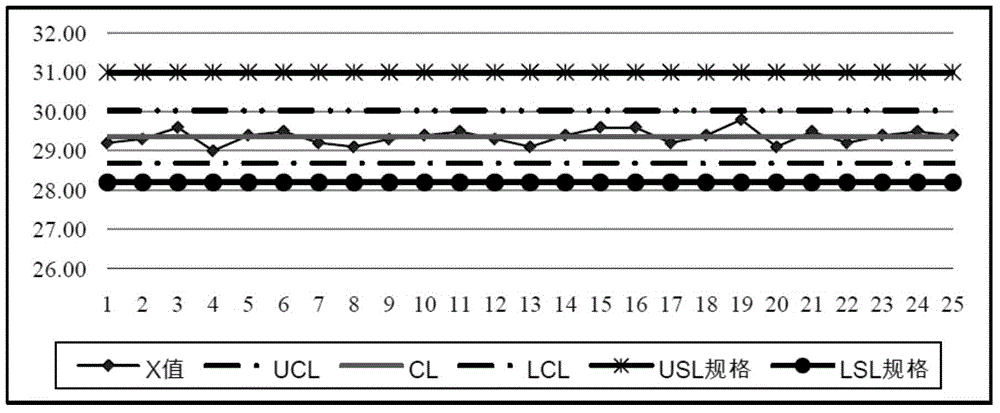

[0028] b) Measure the resistance between the lug area and each point in the coating area, and record the resistance value;

[0029] c) Compare the above resistance value with the set upper and lower limit thresholds, and judge the difference between the resistance values as a whole. If the difference is within the allowable range, it is judged that the coating of the pole piece coating area is uniform; if the difference If the degree exceeds the allowable range, the coating of the pole piece coating area will be uneven.

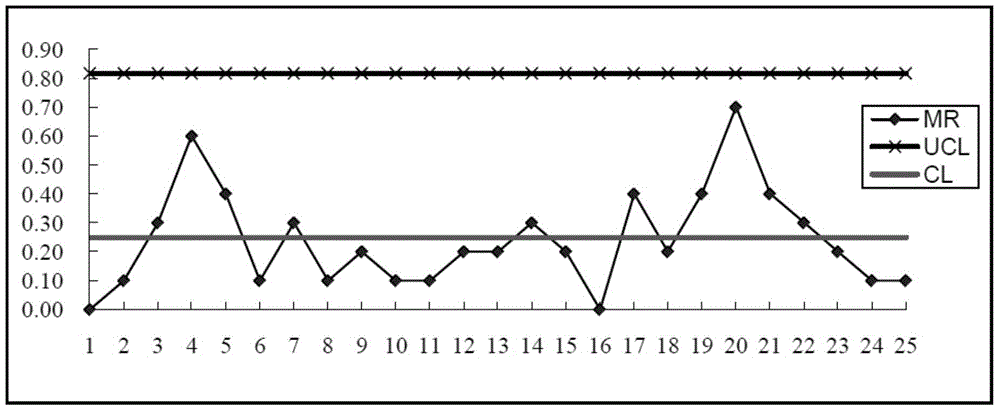

[0030] The discrimination method for judging the difference between the resistance va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com