Puncture wire clamp

A technology for piercing wire clamps and bottom plates, which can be used in the direction of needle point/slotted plate contact parts used to penetrate insulating wires/cable core wires, multi-core cable end parts, etc., and can solve the problem that cannot meet the requirements of large-span main and branch lines Connection, unable to meet the main line and branch line connection, small distance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

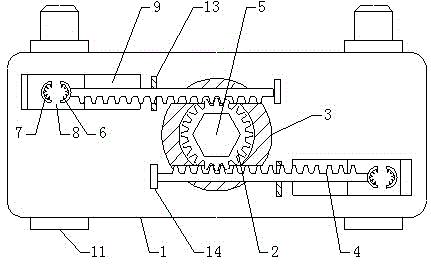

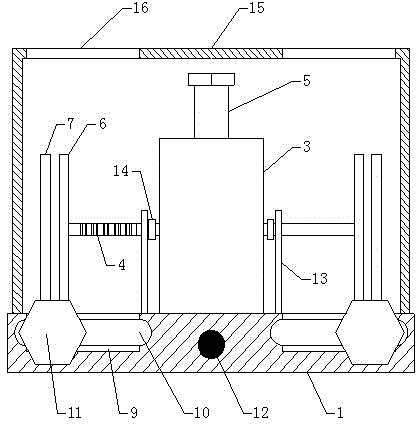

[0014] The present invention will be described in detail below in conjunction with accompanying drawing, as Figure 1-2 Shown: a puncture wire clamp, including a base plate 1, a gear rod 2 vertically arranged on the base plate, a sleeve 3 sleeved outside the gear rod, and a rack 4 that runs through the sleeve horizontally and meshes with the gear rod. The gear rod is rotatably connected with the bottom plate, and the top of the gear rod is provided with a torque nut 5, and the racks are two front and rear ones, and the end of the rack away from the gear rod is provided with a movable puncture blade 6, and a fixed puncture blade is provided facing the movable puncture blade 7. The fixed piercing blade is connected to the bottom plate through the slider 8, the bottom plate is provided with a chute 9 along the length direction of the rack, the slider is slidably connected to the chute, and the front and rear sides of the bottom plate are provided with The chute runs in the same d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com