Universal fine adjustment type space grid joint capable of being assembled and construction method

A technology of grid nodes and assembly space, applied in the direction of architecture, building structure, etc., can solve the problem of low degree of standardization, achieve the effect of high degree of standardization, avoid strength weakening, and reduce construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

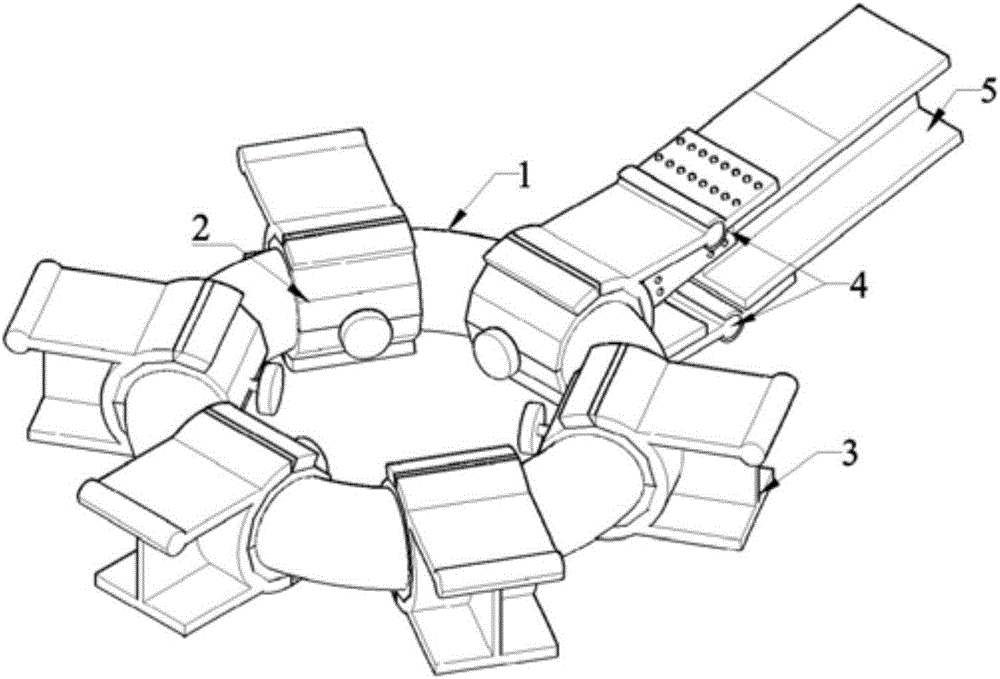

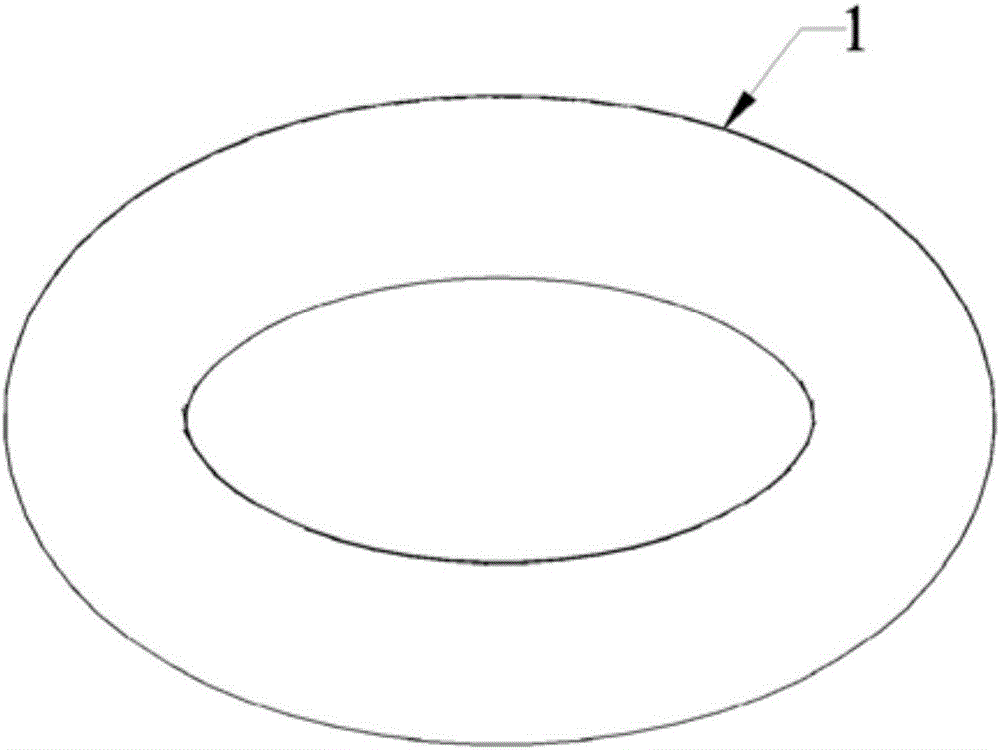

[0017] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment. The universal fine-tuning type assembling space grid node in this embodiment includes a main ring 1, a plurality of corrugated pads 2 and a plurality of connecting units, and a plurality of corrugated pads 2 are arranged along the main ring. 1 is sleeved on the main ring 1 in the circumferential direction, and each corrugated spacer 2 is connected to an H-shaped steel rod 5 through one connecting unit.

specific Embodiment approach 2

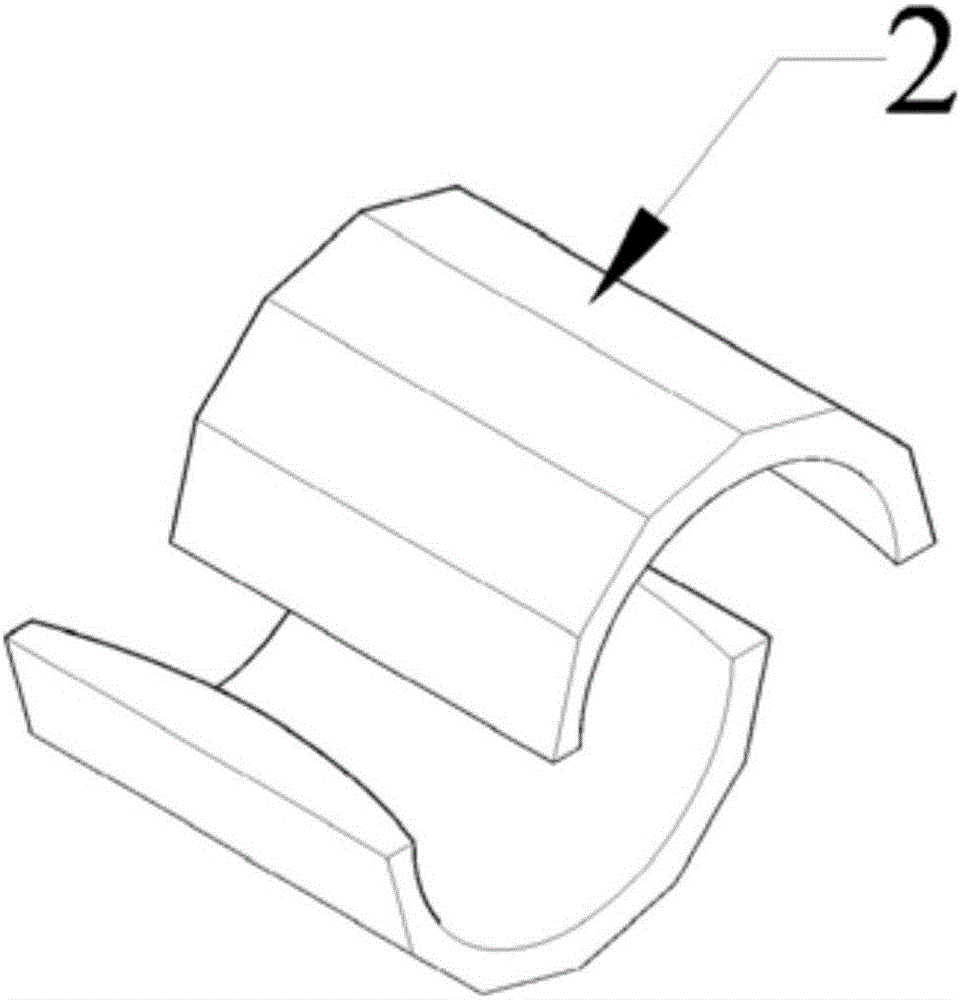

[0018] Specific implementation mode two: combination Figure 1 to Figure 5 Describe this embodiment, each of the connecting units of the universal fine-tuning type assembling space grid node in this embodiment includes a fastener 3 and two connecting plates 4, and the fastener 3 is fastened on the corrugated cushion block 2 , The H-shaped steel rod 5 is connected with the fastener 3 through two connecting plates 4 . Fastener 3 is made up of buckle claw and I-shaped piece, and buckle claw and I-shaped piece are connected together by welding, and fastener 3 is fastened on the belt corrugated pad 2 after welding, and I-shaped piece is connected with two connecting plates 4 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination Figure 1 to Figure 5 To illustrate this embodiment, each connection plate 4 of the universal fine-tuning type assembling space grid node described in this embodiment is connected to the H-shaped steel rod 5 through a plurality of bolts. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com