A light-weight block filling wall and frame structure construction technology

A technology of frame structure and construction technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of reducing service life, affecting appearance, low bearing capacity, etc., and achieves convenient construction, energy and resource saving, and flexible location Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

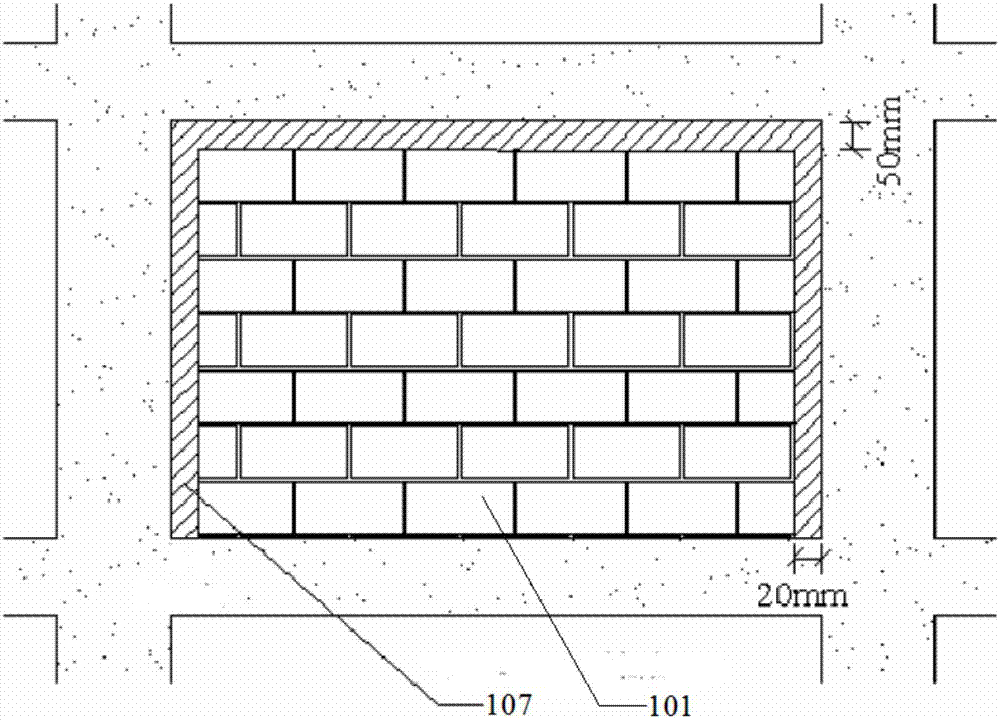

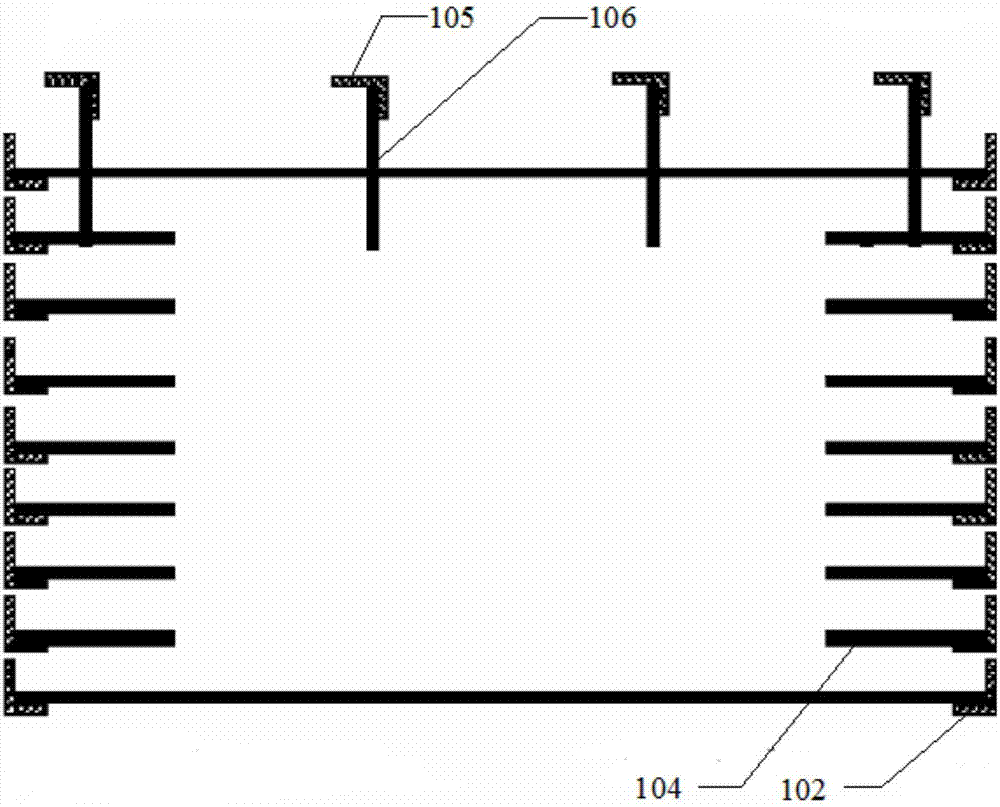

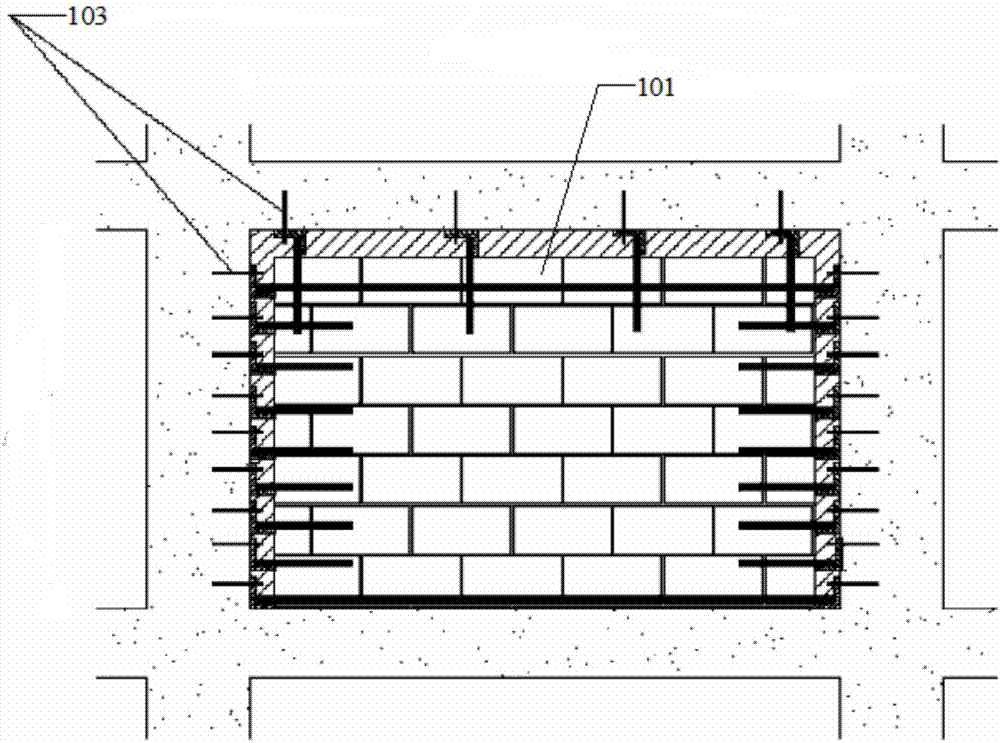

Method used

Image

Examples

Embodiment Construction

[0039] In the prior art, in the rigid connection structure, the infill wall and the frame column are closely connected by masonry, and the infill wall is connected with the beam by oblique masonry, which is a conventional practice at present. After long-term research by the inventor, it has been found that this connection method has the following characteristics:

[0040] (1) Openings such as doors and windows are usually opened in the filling wall. At this time, the filling wall can be used as the transverse elastic support of the frame beam, shortening the calculated span of the frame beam, and easily making the frame beam into a short beam or a deep beam. Under the action of repeated bending and shearing, oblique cracks will expand along the entire length of the beam, so that the ductility and bearing capacity of the beam will drop sharply, making it difficult to meet the seismic requirements of "strong shear and weak bending".

[0041] (2) In terms of the stress and failur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com