Device for attaching elevator guide rail

A technology for installation devices and guide rails, which is applied in transportation, packaging, elevators, etc., can solve the problems of elastic body anti-vibration performance decline, deterioration over time, etc., and achieve the effect of delaying deterioration over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

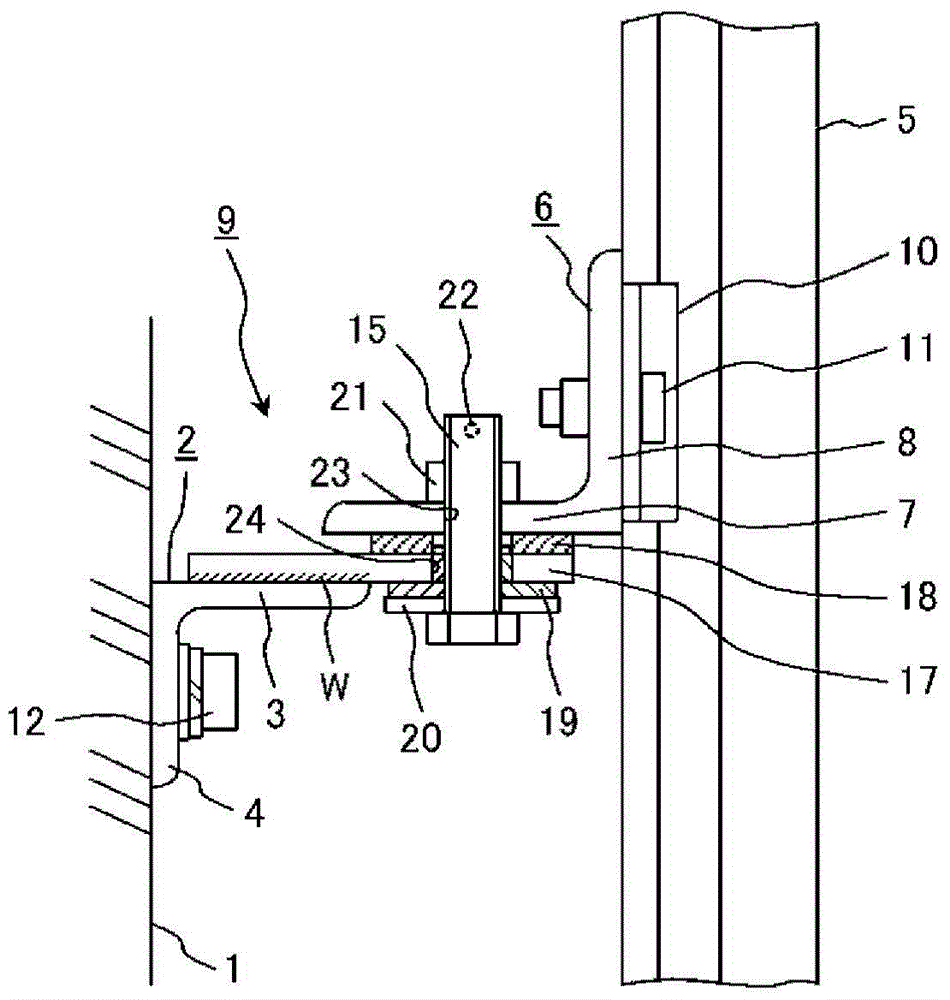

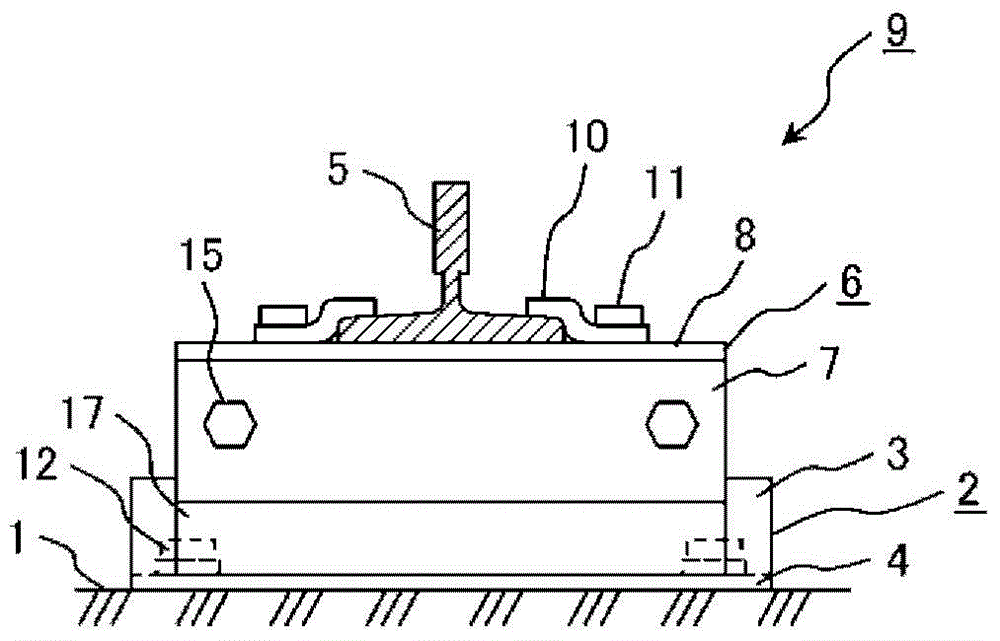

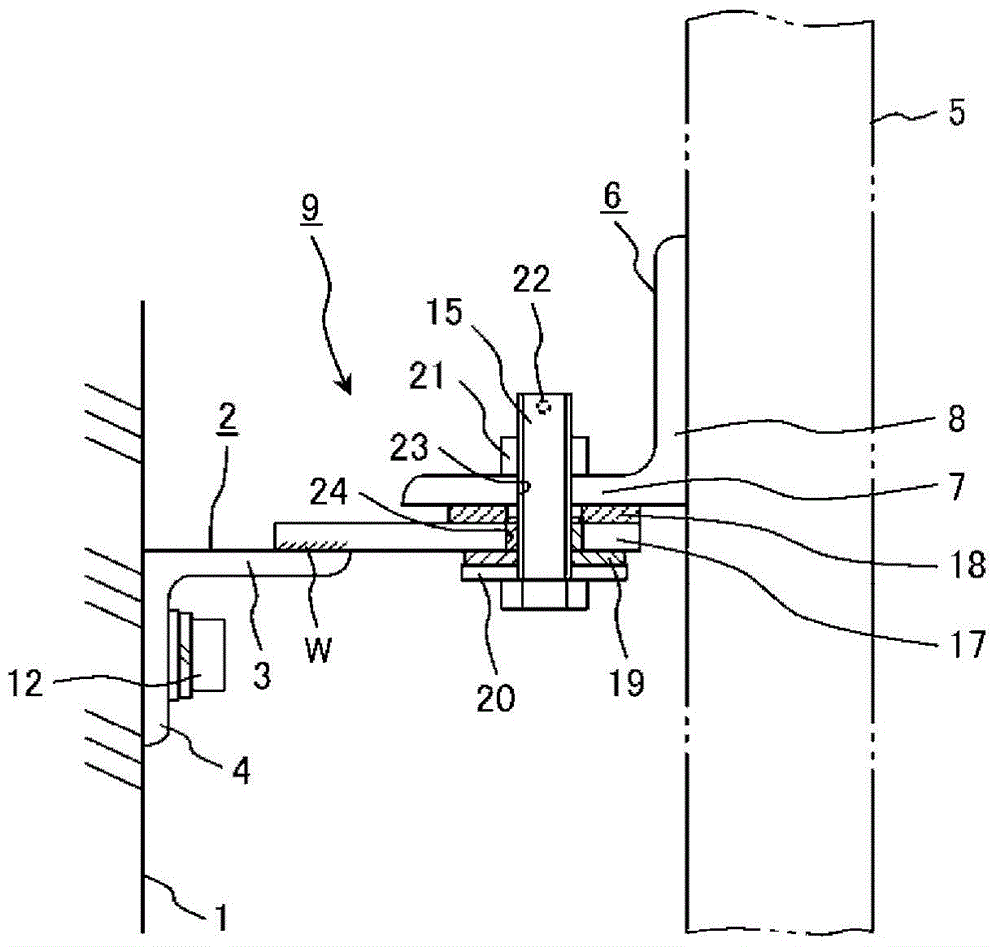

[0036] figure 1 is a side view showing the first embodiment of the present invention, figure 2 It is a plan view showing the first embodiment of the present invention. Such as figure 1 and figure 2 As shown, the first embodiment has a guide rail side bracket 6 for fixing the guide rail 5, a building side bracket 2, and a flat panel bracket 7 arranged between the two brackets.

[0037] The rail side bracket 6 has an L-shaped cross section and has a horizontal piece 7 and a vertical piece 8 . The vertical piece 8 has a through hole into which the bolt 11 is inserted. Two rail clamps 10 for fixing both ends of the rail 5 are fixed to the vertical piece 8 by bolts 11 as fasteners. The horizontal piece 7 has a threaded hole 23 that is threadedly fitted with a bolt 15 as a fastener.

[0038] The cross-section of the building side bracket 2 is L-shaped, and has a horizontal piece 3 and a vertical piece 4 . The building side support 2 has round holes on the vertical piece 4...

Embodiment 2

[0048] In Example 2, such as Figure 4 As shown, as the strength member 28 of the elevator passage, an intermediate beam or a fastening plate arranged on the wall of the elevator passage of the building is used to replace the building side bracket 2, and the flat support 17 is directly fixed on the strength member 28. According to the present invention, as described above, when using the intermediate beam and the fastening plate instead of the building side frame 2, although the degree of freedom of construction is slightly reduced, since there is no need to use new members, the cost of construction can be reduced.

Embodiment 3

[0050] In Example 3, such as Figure 5 As shown, a vise device 29 such as a vise is used instead of the bolt 15 for fixing the guide rail side bracket 6 , the elastic body 18 and the plate bracket 17 and for torque management of the compressive force borne by the elastic body 18 for fixing and torque management. Since the vise device 29 itself can display the tightening torque, torque management can be performed more conveniently. In the present invention, when the vise device 29 is used instead of the bolt 15, the same effect can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com