A composite rotating water outlet assembly

A technology of rotating water outlet and components, which is applied in the direction of spraying device and spraying device with movable outlet, can solve the problems of inability to do both, difficult maintenance, high cost, and achieve perfect human comfort, perfect visual effect, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

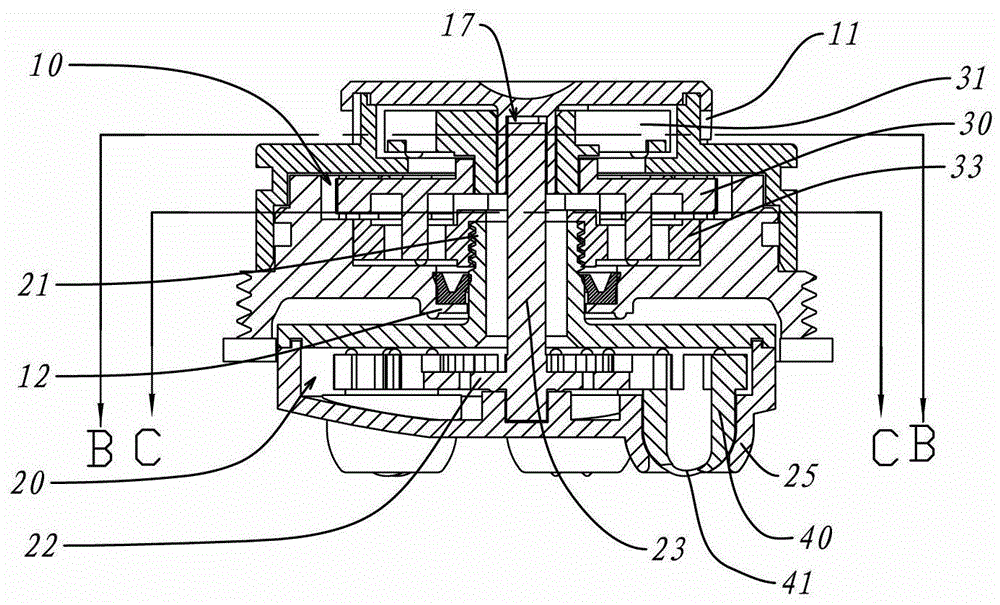

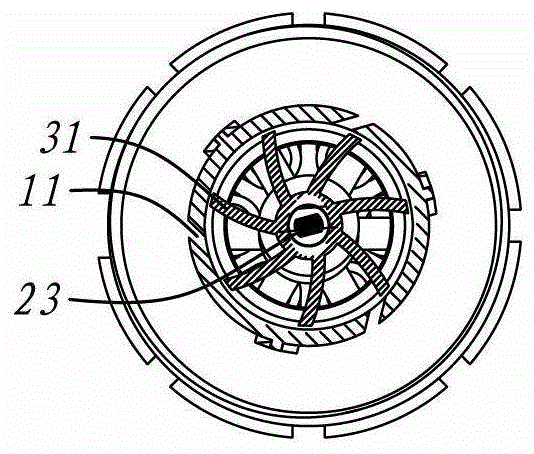

[0036] Such as Figure 1 to Figure 5 Shown is a schematic diagram of Embodiment 1 of the present invention. in Figure 1 to Figure 3 The overall mechanism is shown in the form of cross-section; Figure 4 is its exploded diagram; Figure 5 Details of its emergence from the water are shown.

[0037] In this embodiment, a composite rotating water outlet assembly includes two parts, one is a fixed fluid chamber 10 and the other is a dynamic fluid chamber 20 . As the name implies, the fluid chamber 10 itself is static, while the dynamic fluid chamber 20 is dynamic relative to the stationary fluid chamber 10 .

[0038] The constant fluid chamber 10 has a water inlet 11 and a water outlet 12, and has a power unit inside; The power unit has a power wheel 33 that outputs fixed-axis rotational power.

[0039] The dynamic fluid chamber 20 includes an input port 21 and several output ports 25; the input port 21 is sealed and rotatably fitted to the water outlet 12 of the constant fl...

Embodiment 2

[0050] Such as Image 6 , Figure 7 with Figure 8 Shown is a schematic diagram of Embodiment 2 of the present invention. Image 6 with Figure 7 The internal structure is shown in section,

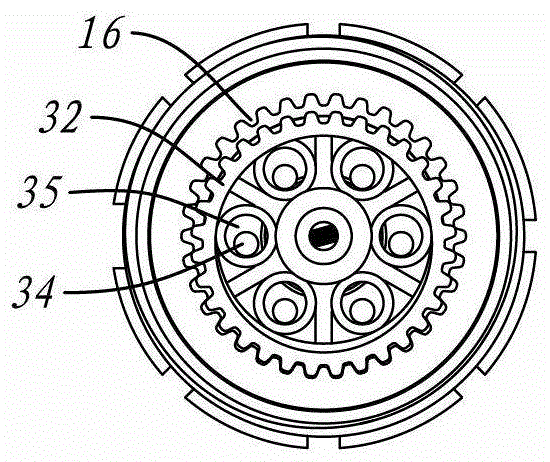

[0051] The impeller mechanism of this embodiment is similar to the first embodiment. But the reduction mechanism is different, including: the first gear 14, the second gear 36 and the third gear 15; wherein the first gear 14 is coaxially fixed on the impeller 11; Coaxially arranged; the third gear 15 meshes between the first gear 14 and the second gear 36 ; the second gear 36 is coaxially fixed on the upper section of the power wheel 33 . The structure is all gear driven, with stable speed and low noise.

[0052] Such as Figure 8 As shown, the matching form of the water outlet 25 and the rotating body 40 in this embodiment is similar to that of the first embodiment, the difference is that the nozzle 41 is cylindrical, which provides a more concentrated water outlet effect.

Embodiment 3

[0054] Such as Figure 9 Shown is a schematic diagram of Embodiment 3 of the present invention.

[0055] The fixed fluid chamber 10 is located in the rotating part 8 of a shower, and the rotating part 8 has a switching hole, which can be matched with the input hole 9. When the rotating part 8 is rotated to a proper position, the switching hole can be aligned with the input hole 9, so that As for the water flow from the shower water channel 91 , it can enter the constant fluid chamber 10 to realize the effect of revolution + rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com