Rubber tyre

A rubber tire and tire technology, applied in the field of rubber tires, can solve the problems of not being able to prevent skid and shock absorption, affect market competitiveness, and increase sales prices, so as to reduce sales prices, enhance competitiveness, and reduce consumption material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

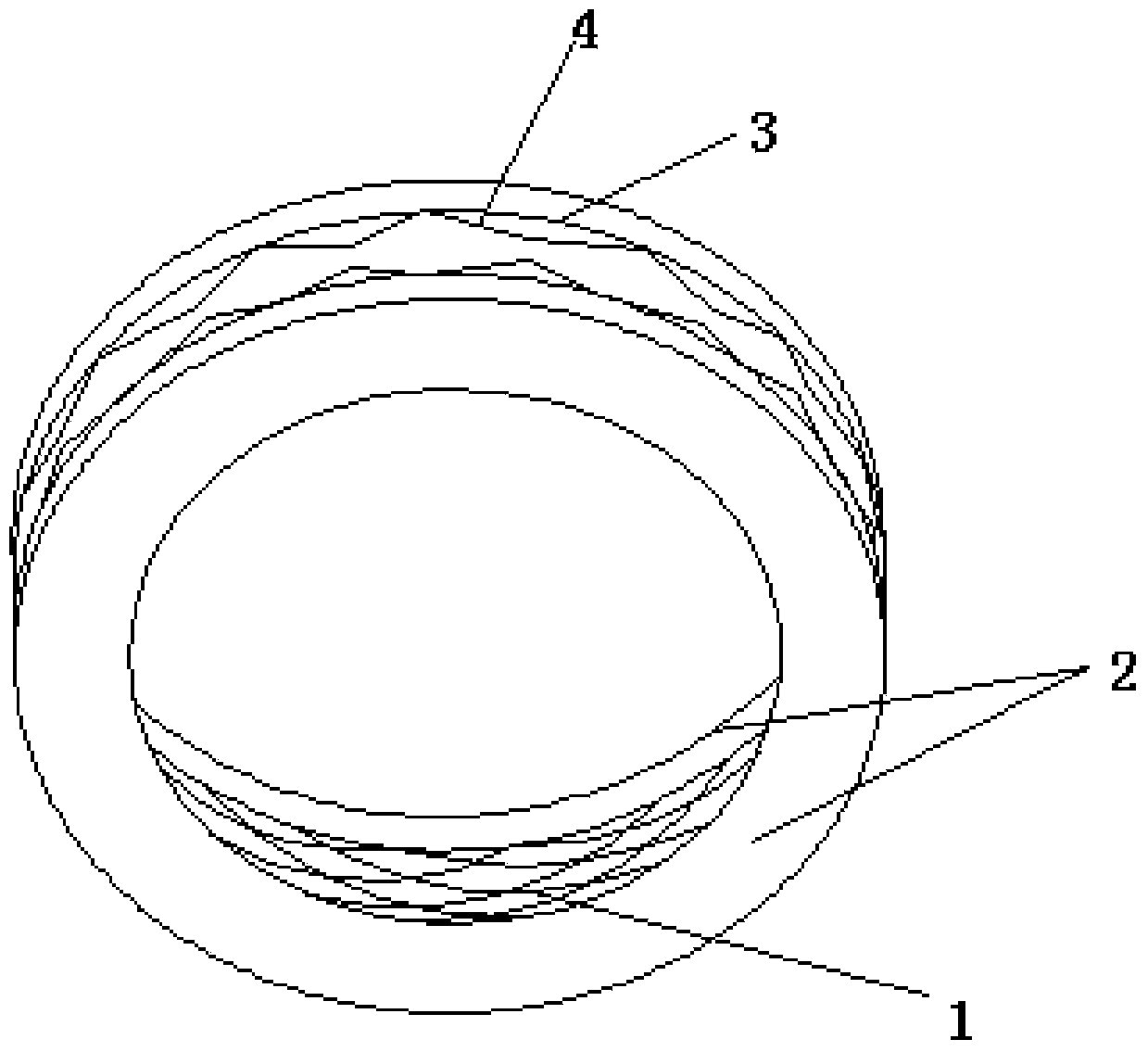

[0012] figure 1 A specific embodiment of a rubber tire of the present invention is shown: a rubber tire, including a tire body, a rib layer is provided on the inner side of the tread of the tire and the inner side of the sidewalls on both sides, and a rib layer is provided on the outer side of the tread of the tire. concave layer.

[0013] Preferably, the rib layer is composed of laterally interlaced ribs.

[0014] Preferably, the inner concave layer is composed of two longitudinal grooves and two wave-shaped grooves, wherein the two wave-shaped grooves are located between the two longitudinal grooves.

[0015] During the running process, the lateral staggered ribs 1 on the inner bottom surface play the role of tire wear resistance, when the wheel is running on a wet road, the longitudinal grooves 3 on the outer bottom surface play the role of anti-skid, and the wavy grooves 4 on the outer bottom surface It not only plays the role of anti-skid but also increases the friction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com