Scrap tire prestressed stadium stands

A waste tire and prestressing technology, applied in the podium and other directions, can solve the problems of high recycling cost, complex process, high raw material processing cost, etc., and achieve the effect of fast construction speed, high efficiency and simplified application method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

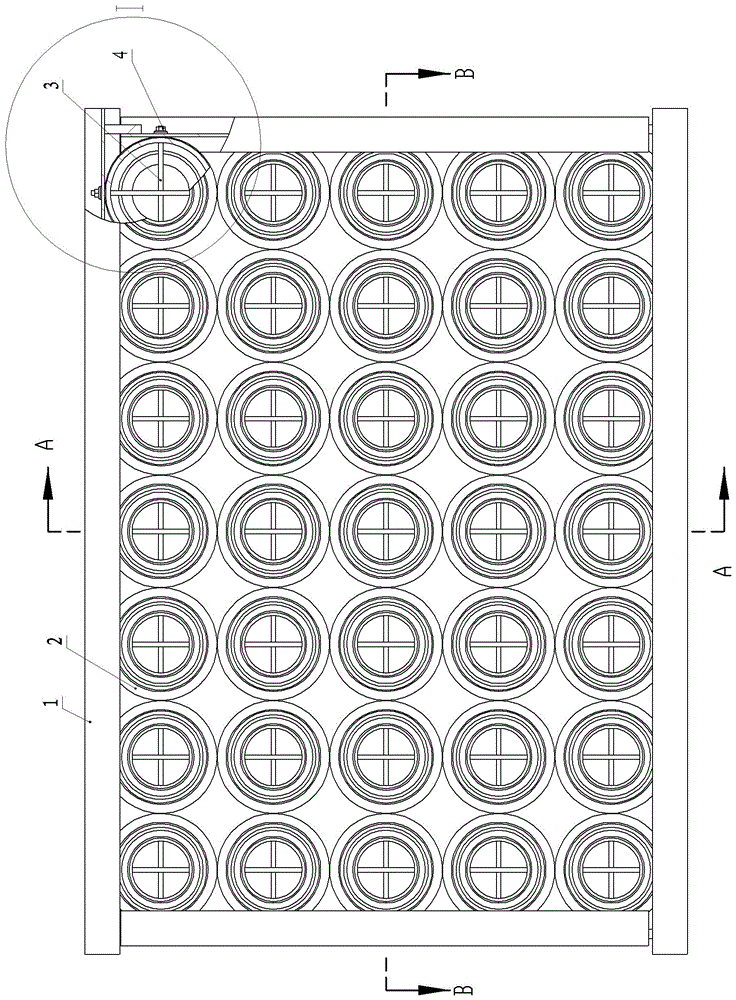

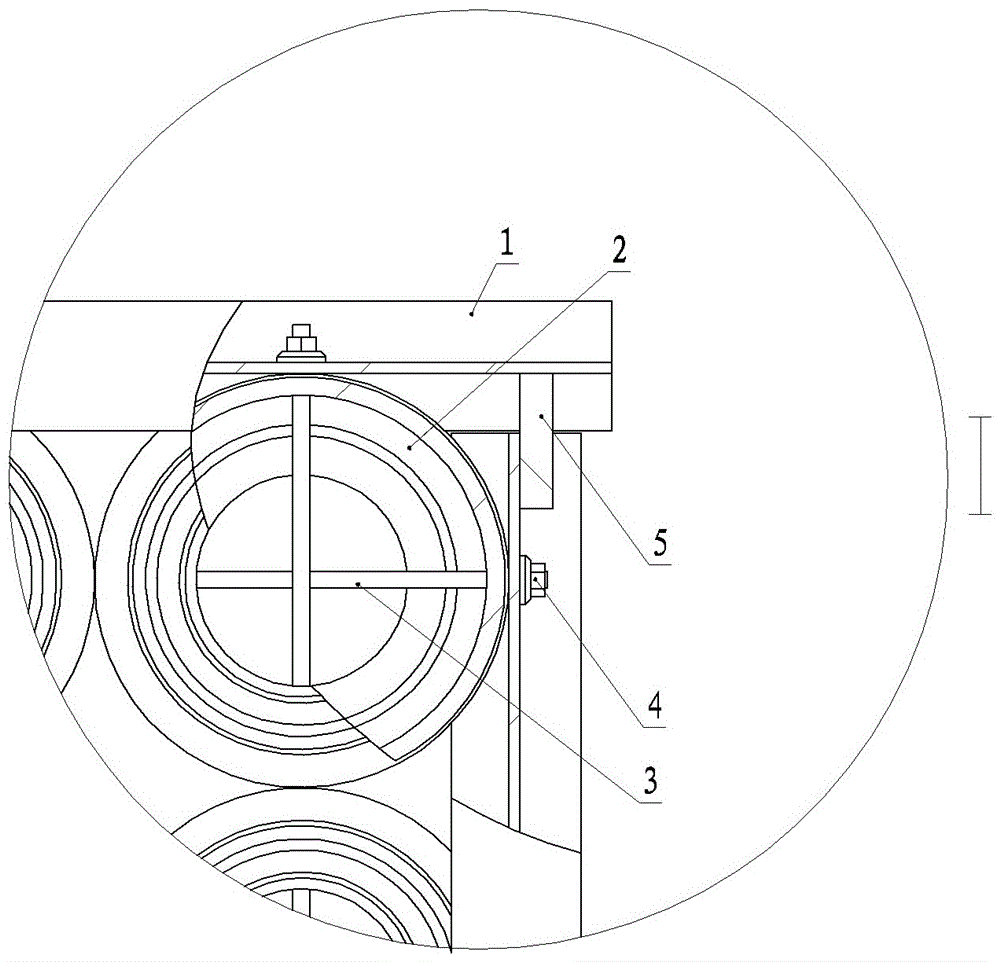

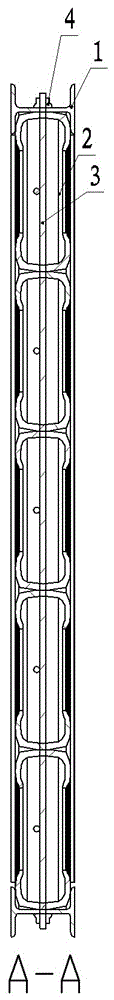

[0018] Embodiment one: see Figure 1-5 , a waste tire prestressed venue stand in the figure, including a total of N groups of prestressed steel frame waste tire mesh arranged in a setback structure from bottom to top, characterized in that: each group of prestressed steel frame waste The tire mesh includes at least a seat layer and a backing layer. The backing layer is superimposed on the same prestressed steel frame waste tire mesh, and the backing layer is behind the seat layer by the width of a waste tire; the seat layer ratio of the N+1 group The backing layer of group N is backed by two waste tires; the inner half of the upper surface of the backing layer of group N is used as the pedal part of group N+1, and the outer half is used as the pedestrian passageway of group N+1 part;

[0019] The prestressed steel frame waste tire mesh sheet includes a number of square waste tires arranged vertically and horizontally, and a steel frame surrounding the waste tires. Prestressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com