High-frequency impact test stand for train bogie

A high-frequency impact and bogie technology, which is applied in impact testing, railway vehicle testing, machine/structural component testing, etc., can solve problems such as impact, and achieve the effects of low test cost, safety protection, and true test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

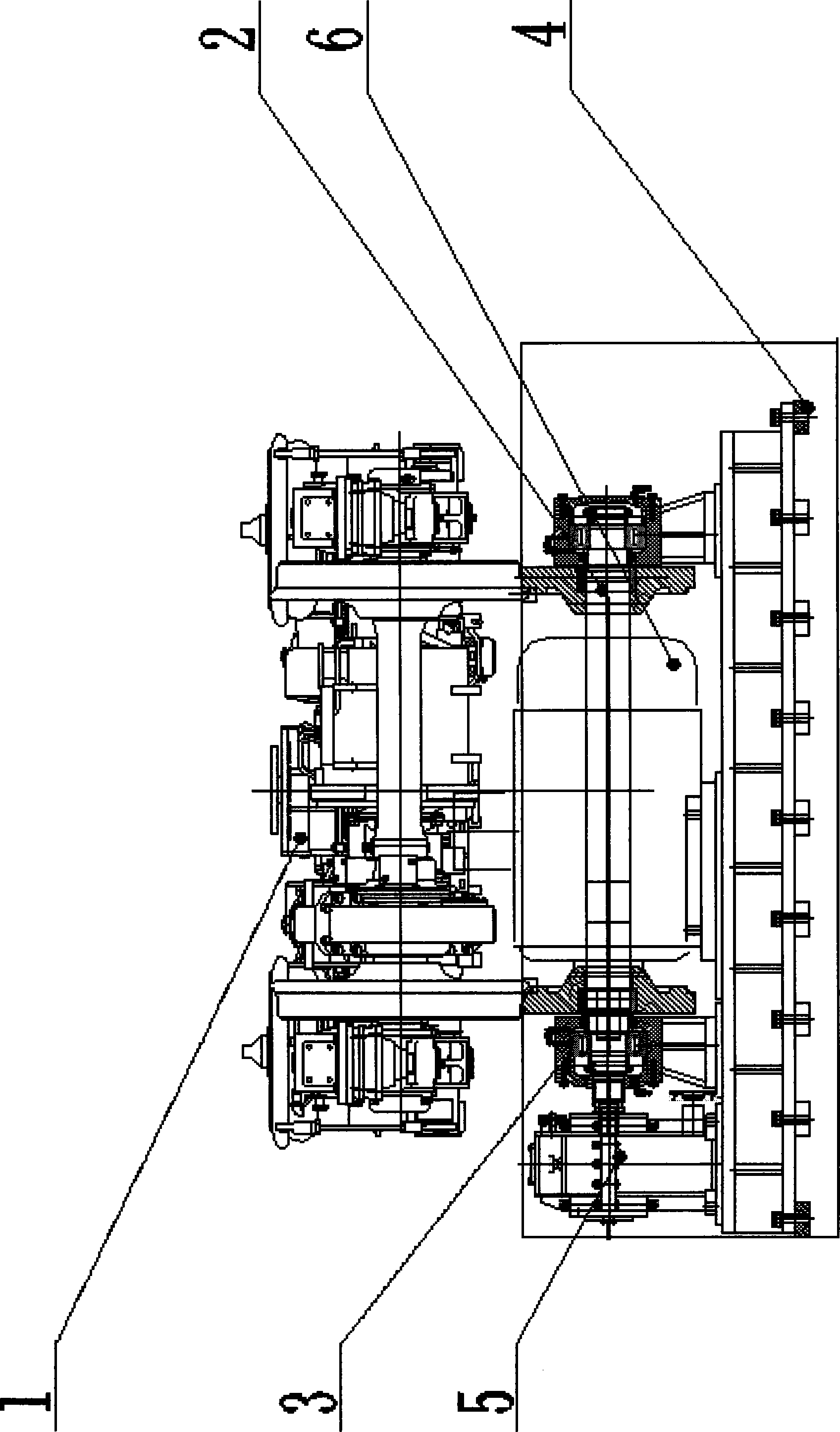

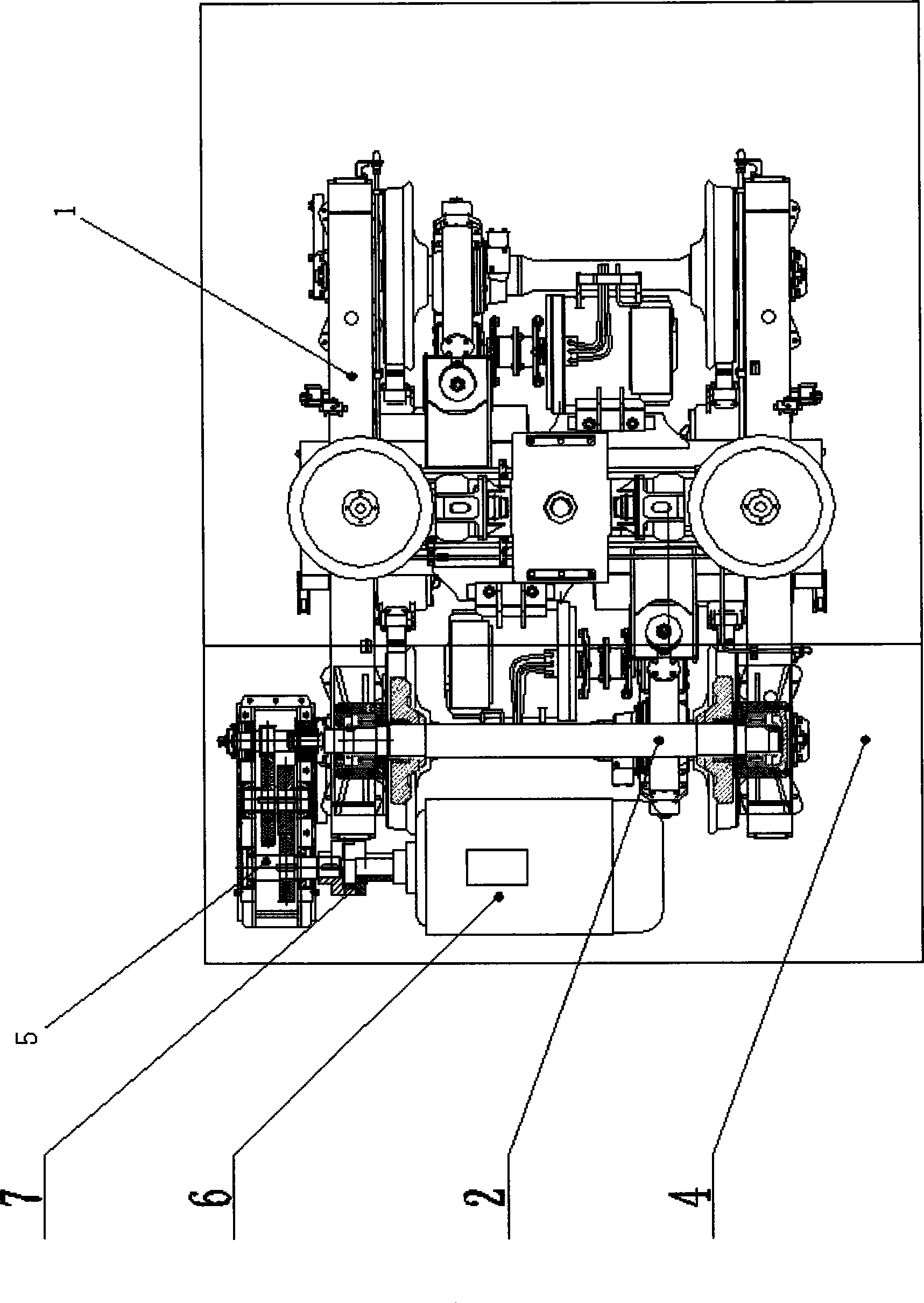

[0028] Figure 1~2 Shown: a kind of embodiment of this invention is: a kind of train bogie high-frequency impact test bench, comprises the train bogie (1) that test is used, the small wheel pair (2) that the bogie (1) bottom rotates at high speed ), the small wheel pair (2) is fixed in the pit of the concave foundation (4) by the wheel pair support (3), and one end of the small wheel pair (2) is connected with a gear box (5), and the gear box (5) The other end of the motor (6) is connected. It is characterized in that: the high-speed rotating small wheel set (2), the wheel set support (3), the gear box (5) and the motor (6) are all installed in the pit of the concave foundation (4). Said bogie frame (1) is placed on the small wheel pair (2) and the concave foundation (4) top.

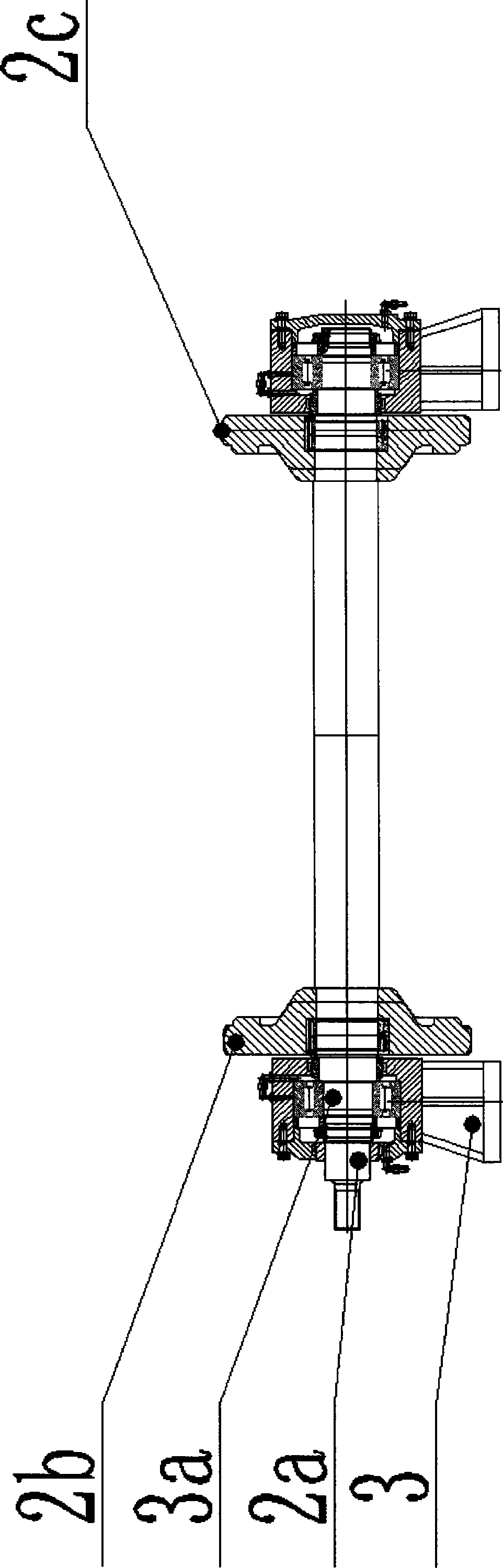

[0029] image 3 and figure 1 Show: the specific composition of the small wheel pair (2) of this example is: the shaft (2a) is fixedly connected with the two wheels (2b), and there are evenly distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com