A kind of LED encapsulation structure and preparation method thereof

A technology of LED packaging and LED chips, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of high production cost, inability to achieve consistency, leakage, etc., and achieve good luminous consistency, good appearance consistency, and production. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

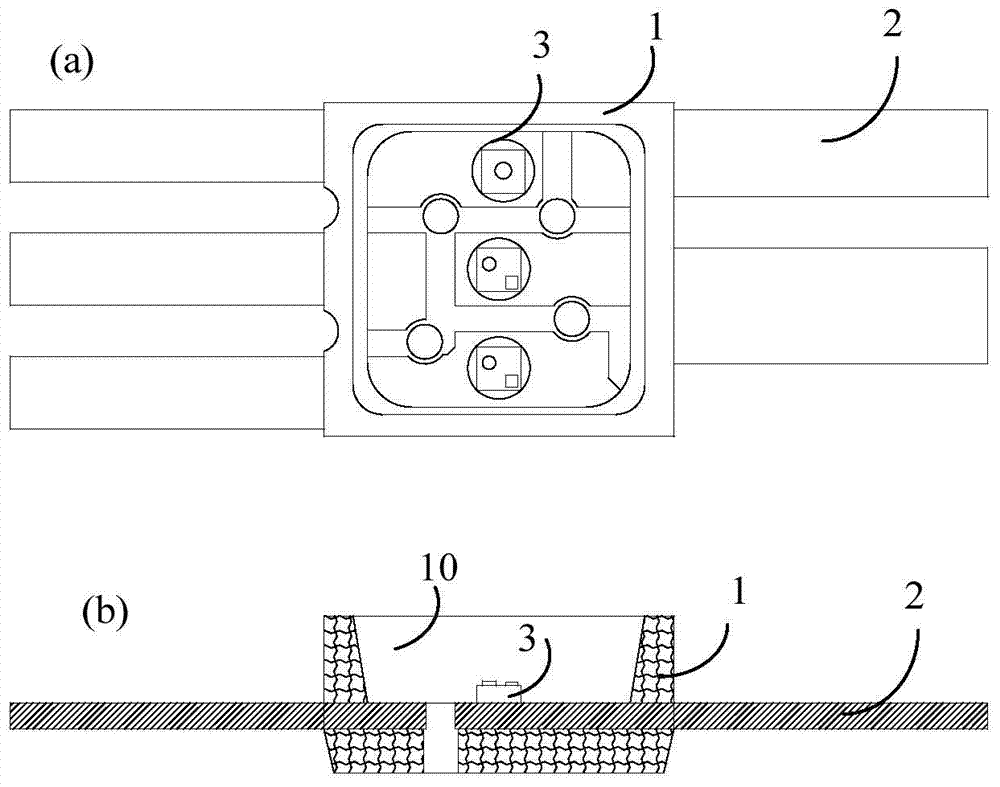

[0038] The difference between this specific embodiment and the first embodiment is that the metal pins of the prepared LED bracket are in a bent state, and correspondingly, the clamping state of the mold is different during the preparation process.

[0039] In the preparation method of the LED packaging structure of this specific embodiment, the preparation process is the same as that of the specific embodiment 1, except that the metal pins of the LED bracket prepared in step 1) are in a bent state, and accordingly the LED bracket in step 4) is in the mold The specific state in the cavity is slightly different, and the processing in step 6) is slightly different. Only this difference will be described in detail below.

[0040] In this specific embodiment, when performing step 4), such as Figure 11 shown. Put the solid and welded LED bracket into the inner cavity of the heat-insulating molding mold. When the LED bracket is loaded, the metal pin 21 is in a bent state, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com