Closed force transmission device and safety door lock using same

A safety door lock, closed technology, applied in locks with spring bolts, building locks, connecting components, etc., can solve the problems of easy switching, high manufacturing costs, and inability to be used, and achieve simple manufacturing processes and excellent durability. , the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

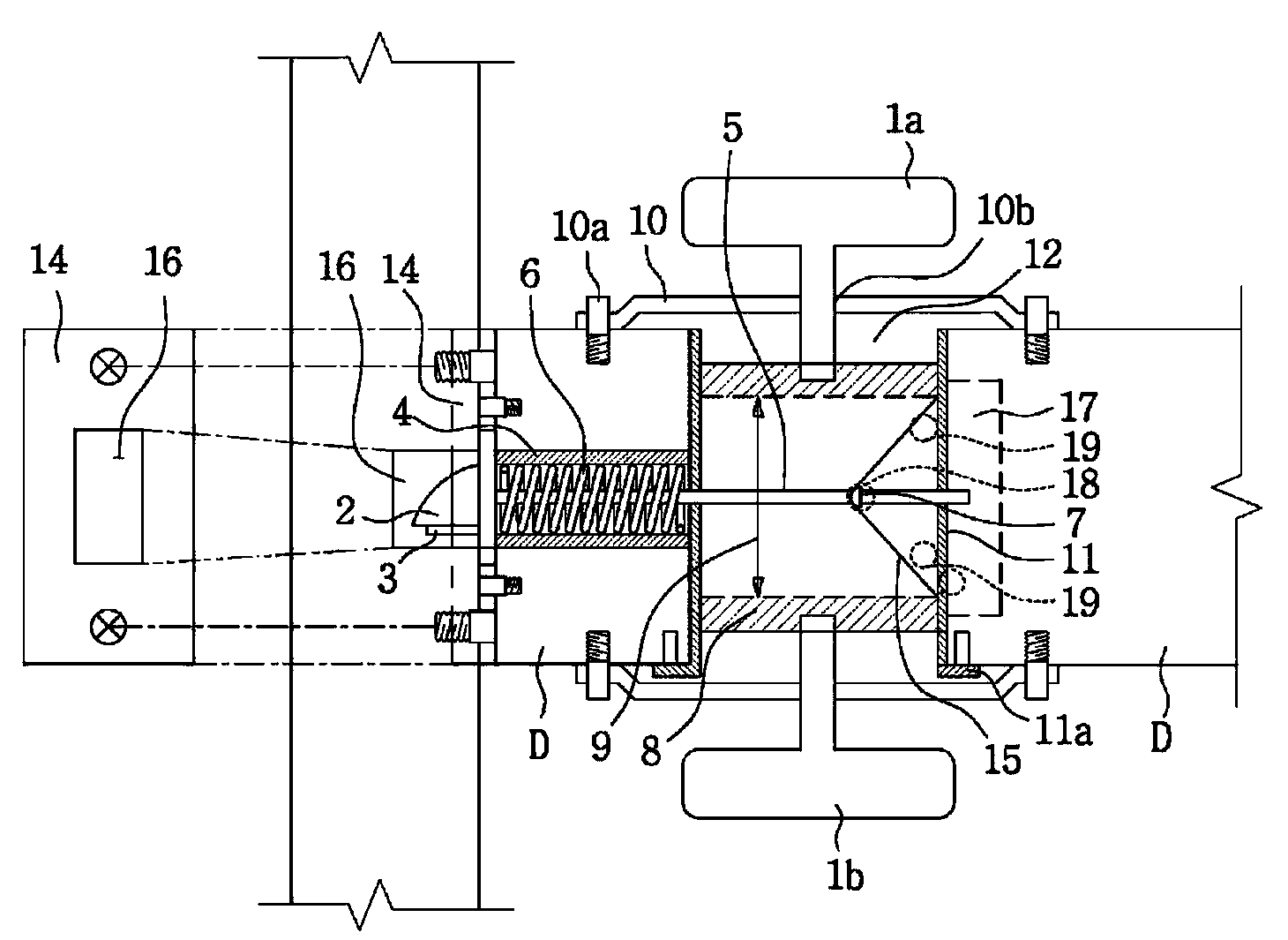

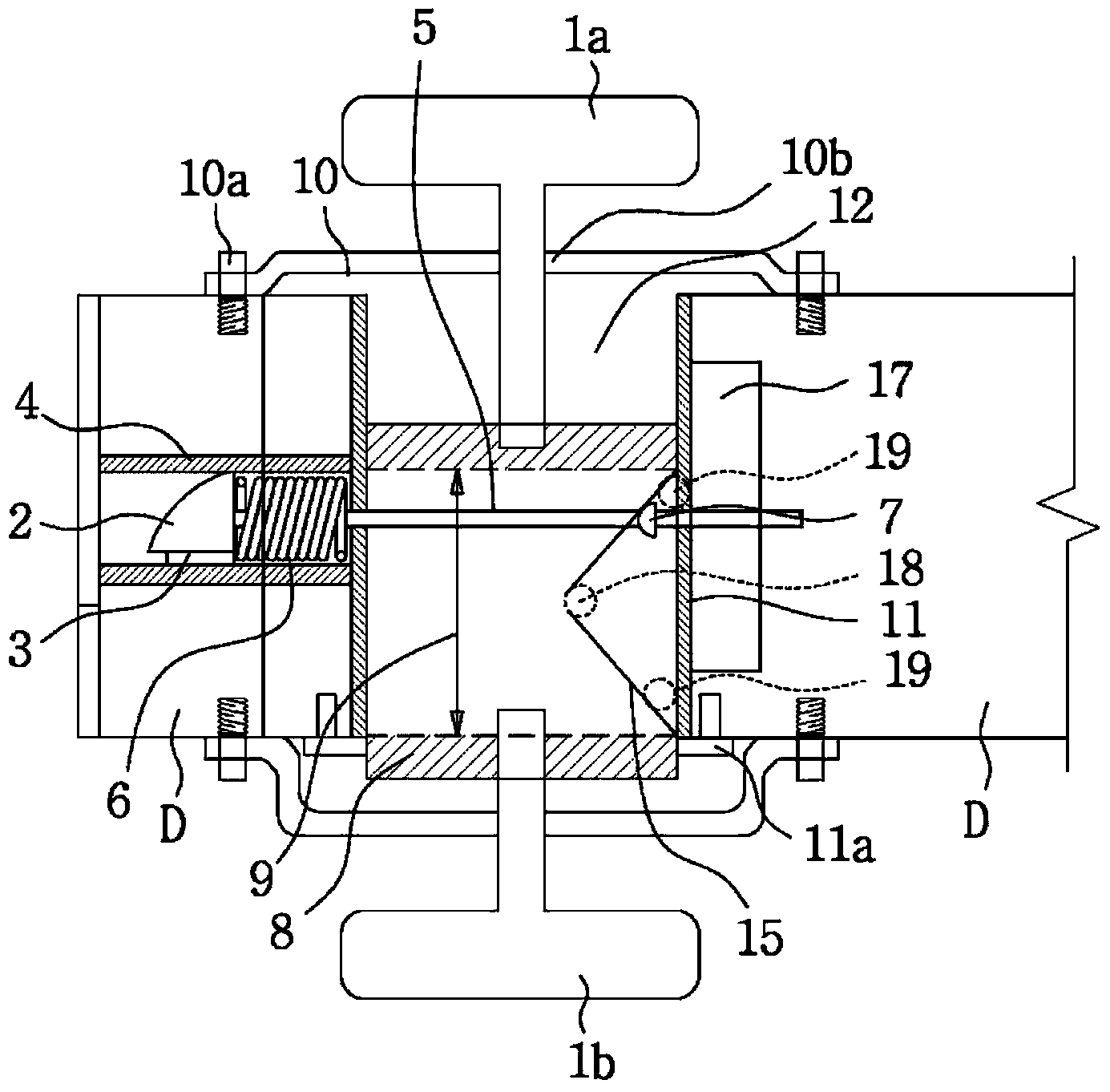

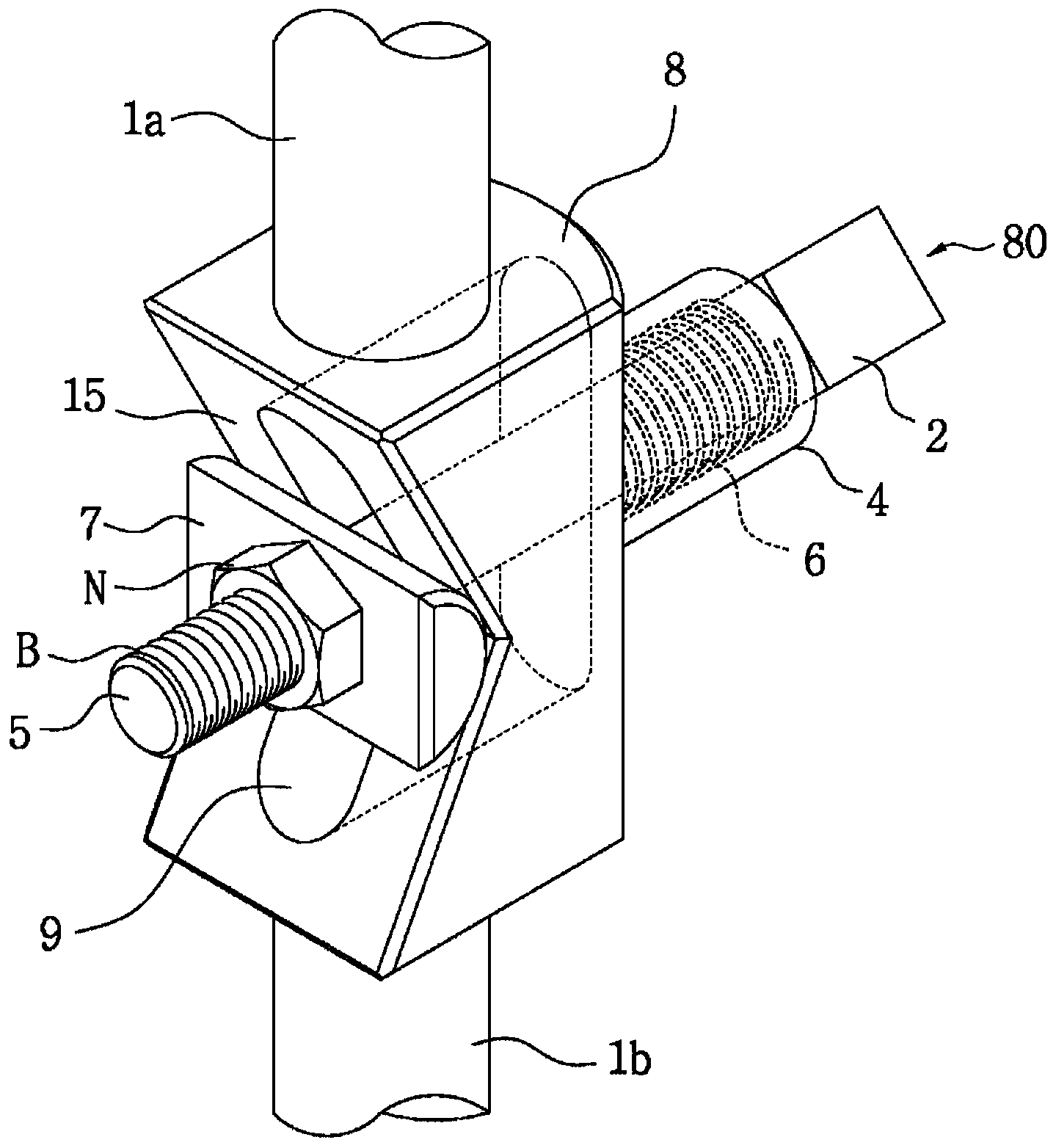

[0048] figure 1 is a schematic diagram showing a state where the safety door lock is closed according to the first embodiment of the present invention, figure 2 is showing figure 1 A schematic diagram of the state where the security door lock is opened, image 3 is a perspective view showing an assembled state of the force transmission device according to the first embodiment.

[0049] refer to Figure 1 to Figure 3 , The door lock includes a force transmission device and a handle 1a, 1b arranged on the door D. The force transmission device includes a body 8 and a bolt assembly 80 , and may also include a body shell 11 .

[0050] This door lock has a body shell 11, a body 8, handles 1a, 1b, and a bolt assembly 80, wherein the two sides of the body shell 11 are opened along the direction formed by the through holes 12 penetrating th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com