A control method to solve the steel jamming of the jaws of the coiler

A control method and card technology, applied in the field of steel rolling control, can solve the problems of card steel, the inner ring of the card steel coil, and the clamping jaw, so as to achieve the effect of improving quality and fast rolling rhythm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

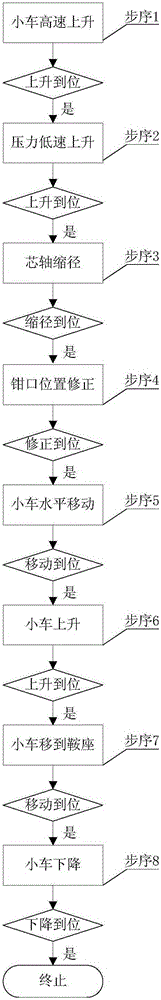

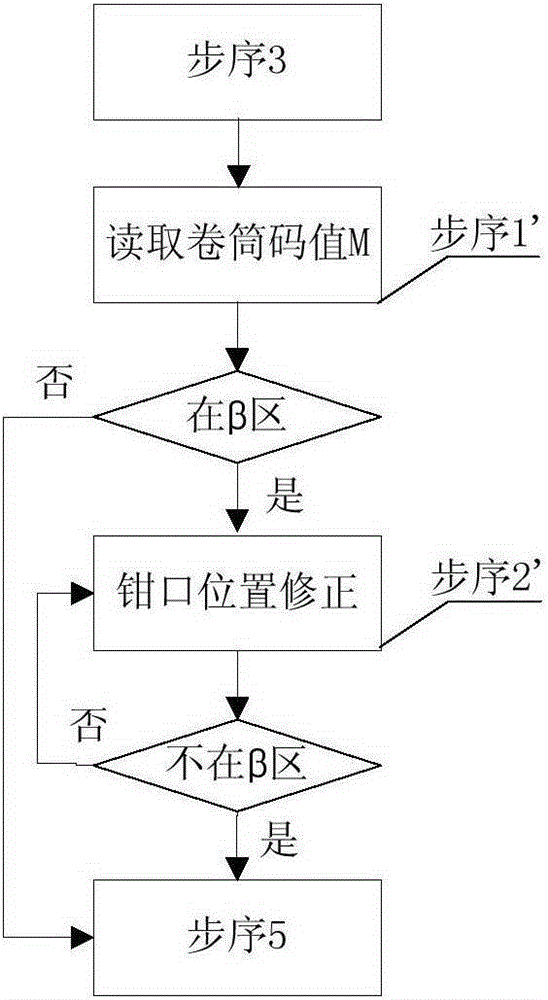

[0024] In the original common control steps, the present invention adds jaw position correction steps 4 such as image 3 . The specific control method is:

[0025] In the process of automatic unloading, after the unloading trolley rises to the position (step 1, step 2) and the diameter of the reel shrinks (step 3), start the control step 4: jaw position correction control such as image 3 , and its control steps are:

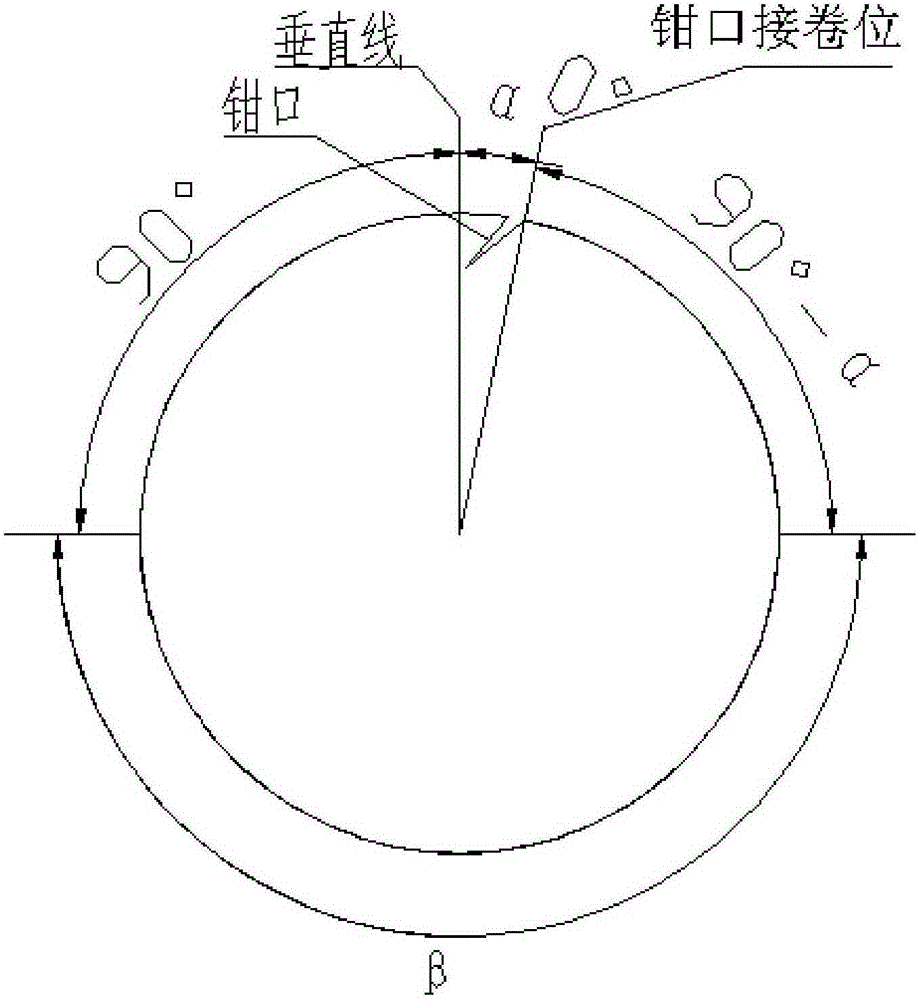

[0026] 1. Step 1': The control system reads the number of the code disc of the coiler and converts it into an angle code value M, which is the position angle code value of the jaw, and judges whether the position angle of the jaw is at figure 2 The β region, if the jaw position is not in figure 2 β area, then execute step 5; if the jaw is in figure 2 β area, then perform the following steps.

[0027] 2. Step 2': The reel rotates along the strip coiling direction, when the position of the jaw is not figure 2 When the position of the β region is reached,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com