Vertical conveyor

A technology of vertical conveyor and circular conveying, applied in the field of vertical conveyor, can solve the problems of high labor intensity, low efficiency, easy fatigue, etc., and achieve the effect of safe conveying operation, low efficiency and high transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

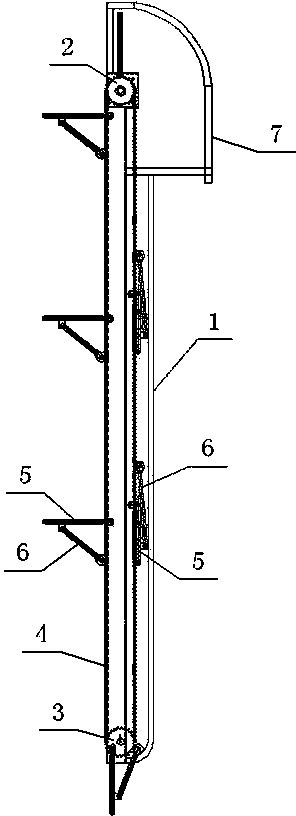

[0018] Embodiment 1: A vertical conveyor, including a frame body 1, on which a driving sprocket set 2 and a driven sprocket set 3 are arranged, and the driving sprocket set 2 is driven by a frequency conversion motor, The rotation speed and steering can be adjusted conveniently according to the needs. The driving sprocket set 2 is composed of two symmetrical coaxial driving sprockets on the left and right, and the driven sprocket set 3 is composed of two left and right symmetrical coaxial driving sprockets. The driving sprocket is composed of the driven sprocket, and the driving sprocket corresponds to the driven sprocket up and down. A matching transmission chain group 4 is arranged between the driving sprocket set 2 and the driven sprocket set 3, The transmission chain group 4 is composed of two symmetrical transmission chains on the left and right, each transmission chain is set on a set of corresponding driving sprockets and driven sprockets, and the two transmission chains...

Embodiment 2

[0021] Embodiment 2: In this embodiment, the driving sprocket set 2 is composed of three coaxial driving sprockets left, middle and right, and the driven sprocket set 3 is composed of three coaxial left, middle and right sprockets. The driven sprocket is formed, and the transmission chain group 4 is composed of three symmetrical transmission chains in the left, middle and right. Two adjacent transmission chains form a circular conveyor chain group, that is, the left and middle two transmission chains form the first circular conveyor chain group, and the middle and right transmission chains form the second circular conveyor chain group. The rest of the structure of this embodiment is the same as that of Embodiment 1. Compared with Embodiment 1, this embodiment has one more cycle conveyor chain group. Under the same working hours, its efficiency is twice that of Embodiment 1.

[0022] Of course, it can also be that the left, middle and right transmission chains form a circular c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com