A kind of high temperature resistant anti-seismic steel bar and its production method

A technology of anti-seismic steel bar and high temperature resistance, applied in the field of high temperature and anti-seismic steel bar and its production, can solve the problems of inability to meet high temperature resistance, complex steel bar process, unsatisfactory seismic performance, etc., and achieve the effect of satisfying seismic performance and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

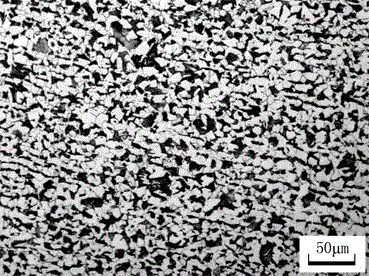

Image

Examples

Embodiment Construction

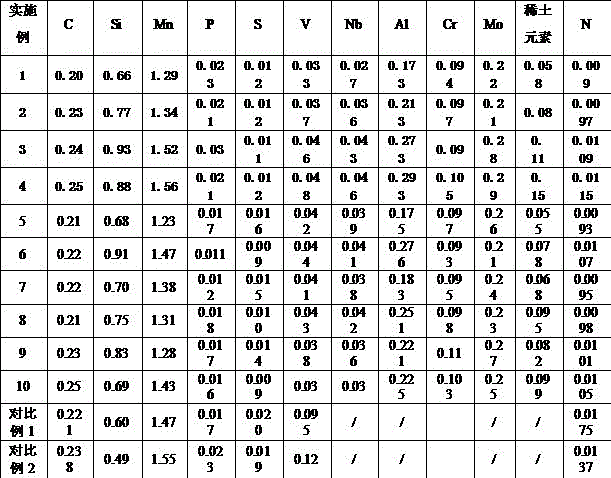

[0039] The present invention is described in detail below:

[0040] Table 1 is the value list of each embodiment of the present invention and comparative examples;

[0041] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0042] Table 3 is a list of performance monitoring conditions of each embodiment of the present invention and comparative examples.

[0043] Each embodiment of the present invention is produced according to the following steps:

[0044] 1) Desulfurize the molten iron, and use magnesium powder for desulfurization, control the S≦0.01% in the molten iron after desulfurization, and operate without leaving slag;

[0045] 2) Carry out converter smelting: use top-bottom compound blowing, control the amount of non-steel added to account for 10-15% of the total charge in the furnace; point out no more than two times; control the final slag basicity at 2.8-3.8; end point C Not less than 0.08%; control ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap