Building external wall insulation AAC composite wallboard structure assembling method based on structural column

A technology for building exterior walls and assembling methods, which is applied to building structures, building thermal insulation materials, building components, etc., can solve the problem that single-layer AAC plates do not meet the thickness of self-insulating walls, do not involve the thickness of thermal insulation wall panels, and do not meet the requirements of assembly. It can achieve the effect of fast implementation, easy popularization and use, and simple and stable construction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

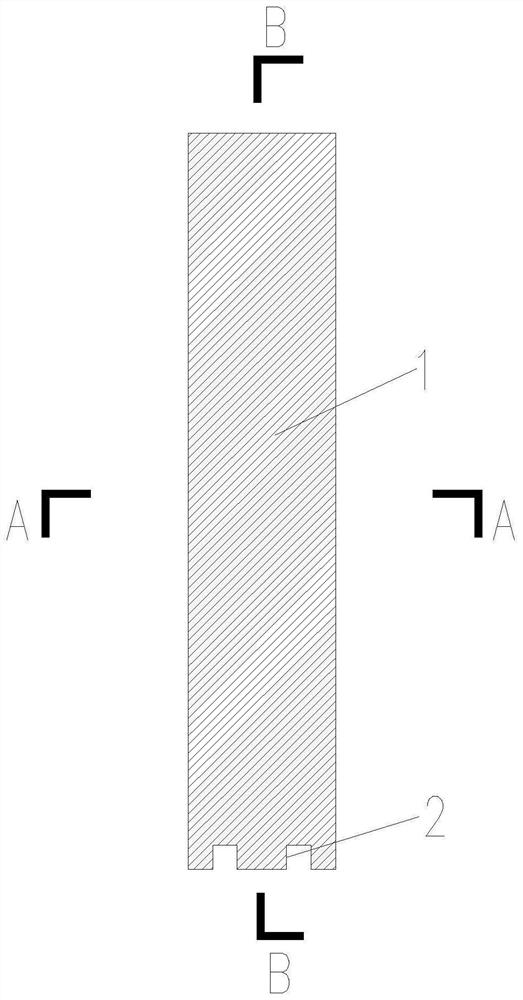

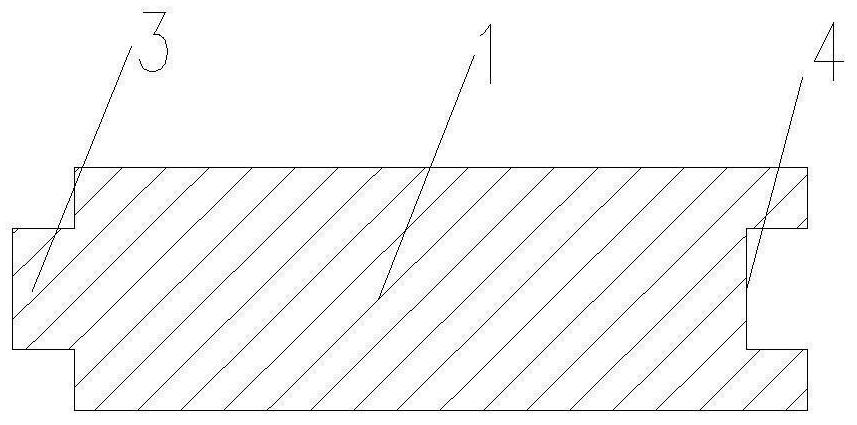

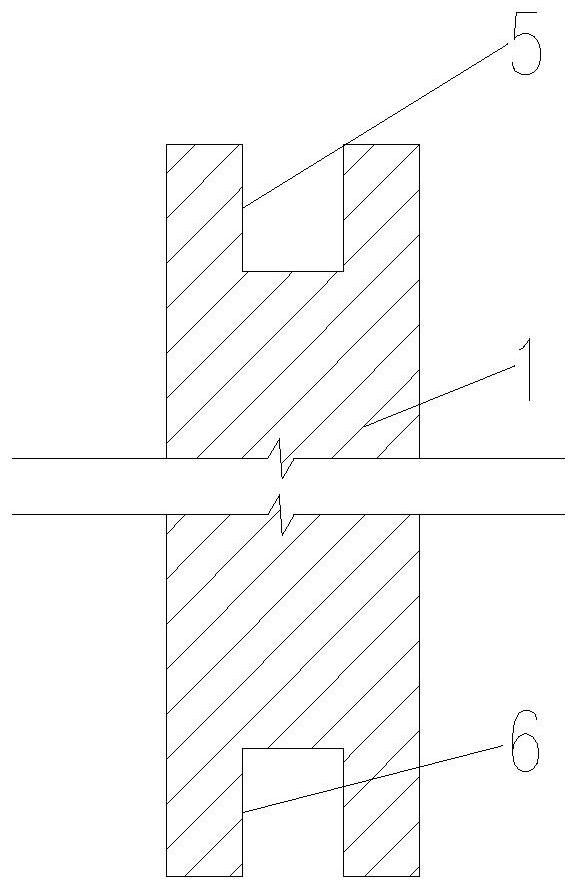

[0051] Such as Figure 1 to Figure 10 As shown, the building exterior wall thermal insulation AAC laminated wall panel construction and assembly method based on structural columns of the present invention comprises the following steps:

[0052]Step 1. According to the design drawings, prefabricate laminated beams, structural columns, thermal insulation AAC laminated wall panels and water-stop reverse sills;

[0053] The top of the composite beam 19 is pre-embedded with a reserved steel bar 20, and the bottom of the composite beam 19 is provided with a composite beam groove that fits with the square steel 21;

[0054] The top of the waterproof anti-sill 12 is provided with an anti-sill projection 13 along the length direction, and the anti-sill projection 13 is provided with a plurality of positioning grooves 14 along the length direction. The waterproof anti-sill 12 is a prefabricated waterproof anti-sill, and the prefabricated waterproof anti-sill A grouting sleeve 16 matchi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap