Fabricated wall body and installation structure and installation method thereof

A prefabricated, wall technology, applied in the direction of building structures, walls, building components, etc., can solve the problems of difficult disassembly, inconvenient replacement, low seismic and shear resistance, etc., to shorten the construction period, improve assembly efficiency, and ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

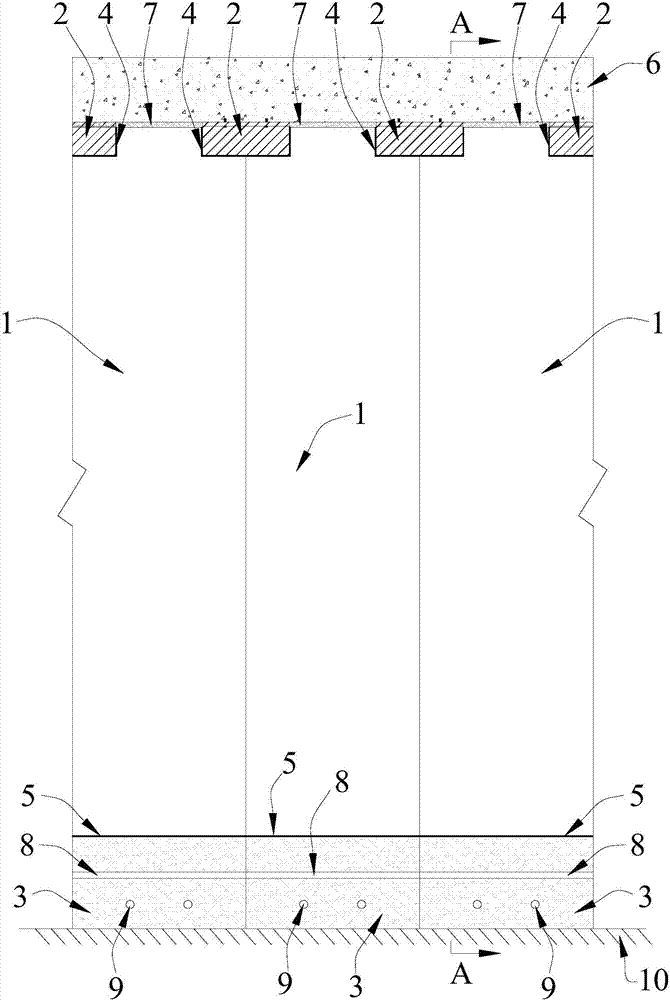

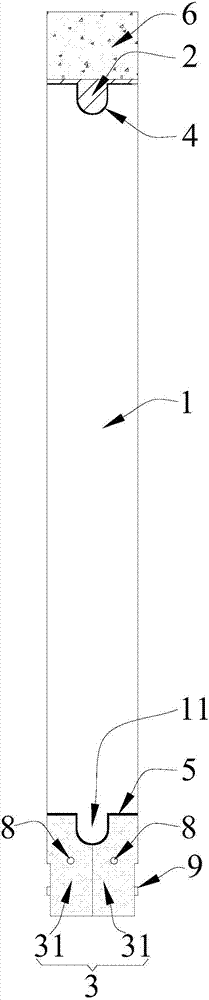

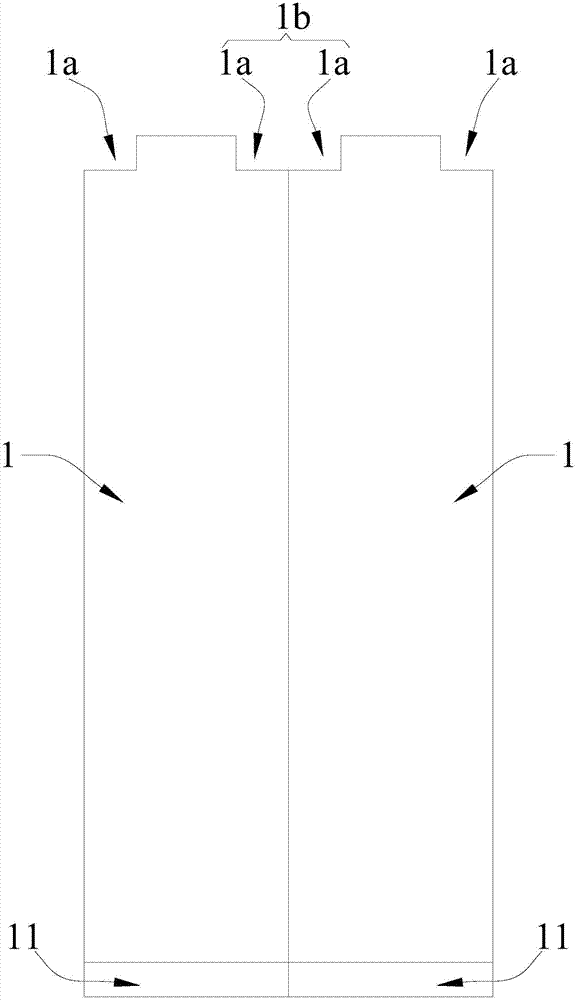

[0036] In order to enhance the stability of the anchor falcon 3 to the fixing of the prefabricated wall panel 1, as a preferred embodiment of the present invention: the two anchor falcon halves 31 of each anchor falcon 3 are fixed by a mechanical connection; the mechanical connection The way can be but not limited to the bolt and nut 9 connection way.

[0037] In order to facilitate the laying of electric wires in the wall, as a preferred embodiment of the present invention: a cable pipe 8 is pre-embedded in each anchor 3 .

[0038] As a preferred embodiment of the present invention: the prefabricated wallboard 1 and the anchor falcon 3 are all prefabricated by concrete materials, the connecting member 2 is made of metal materials, and the bonding material layer 4 adopts structural glue or polymer resin or sticky glue etc. are applicable to the bonding material between the metal contact surface and the cement contact surface, and the first bonding material layer 5 is made of c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap