Ultrasonic detection device and system for underground rock mass fissure drilling

A detection device and a technology for rock mass fissures, which are applied in the directions of measurement, earthwork drilling, borehole/well components, etc., can solve the problems of uninterpretable crack development around boreholes, low detection accuracy, low intelligence, and inability to measure with ultrasonic waves and other problems, to achieve the effect of simple design, comprehensive functions and short construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

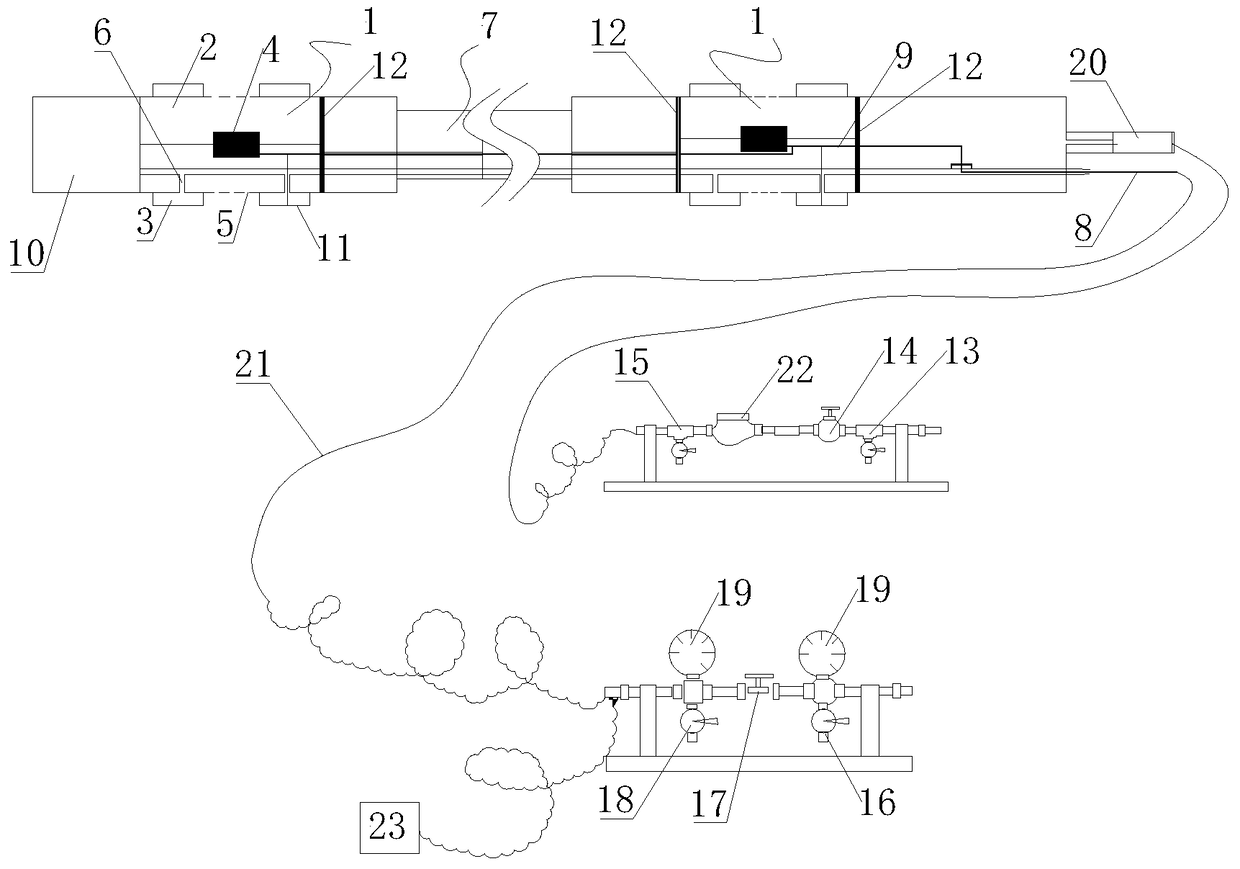

[0018] Please refer to figure 1 , the present invention provides an ultrasonic detection device for underground rock mass fissure drilling, including: two detection parts 1, including a housing 2, two air bags 3 arranged outside the housing 2, and an air bag located between the two air bags 3 In the ultrasonic transducer 4, the casing 2 is provided with a water leakage hole 5 on the circumferential side wall between the two airbags 3, the casing 2 is provided with an air hole 6 on the circumferential sidewall corresponding to the airbag 3, and the airbag 3 and the airbag 3 are connected to each other. The air hole 6 is connected; the connecting part 7, the two detection parts 1 are connected through the connecting part 7; the air pipeline 8 is connected to the air holes 6 of the two detection parts 1 respectively, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com