Novel sleeve type buried pipe

A casing type, buried pipe technology, applied in the field of ground source heat pump, can solve the problems of increasing the impact of the water flow limit ring, easy to loose, affecting the service life of the buried pipe, etc., to improve heat exchange efficiency, avoid cold Heat offset, fixed and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

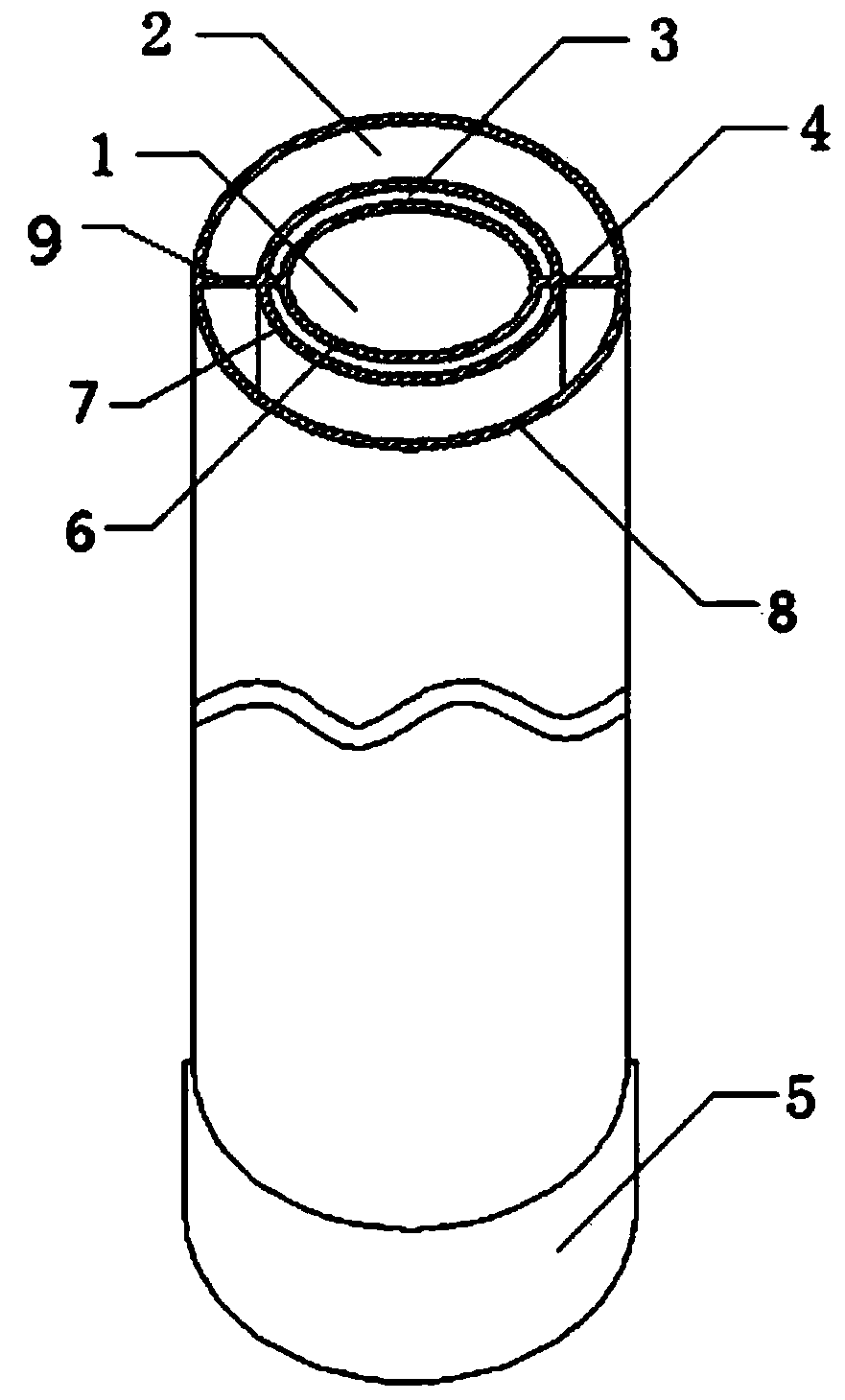

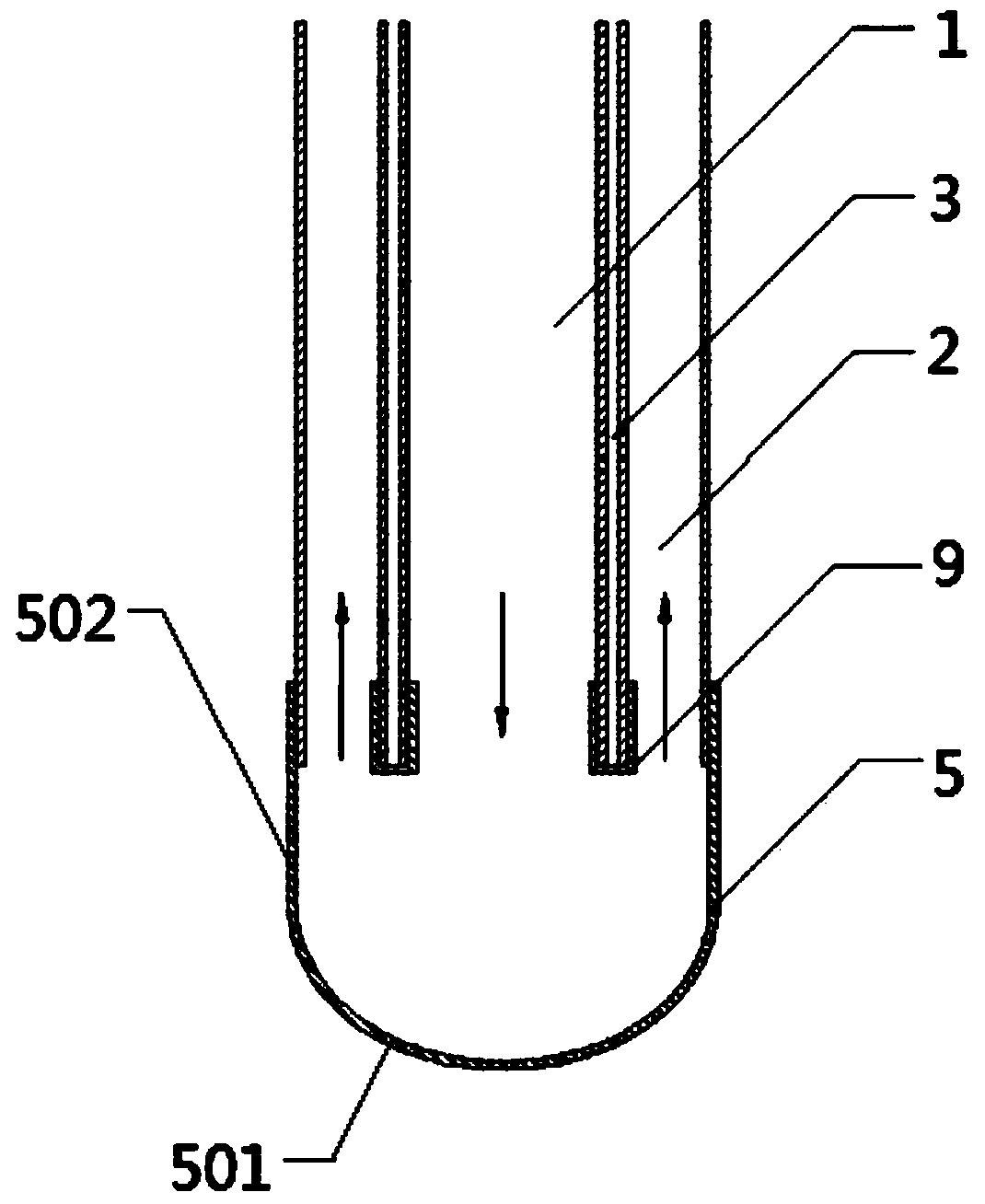

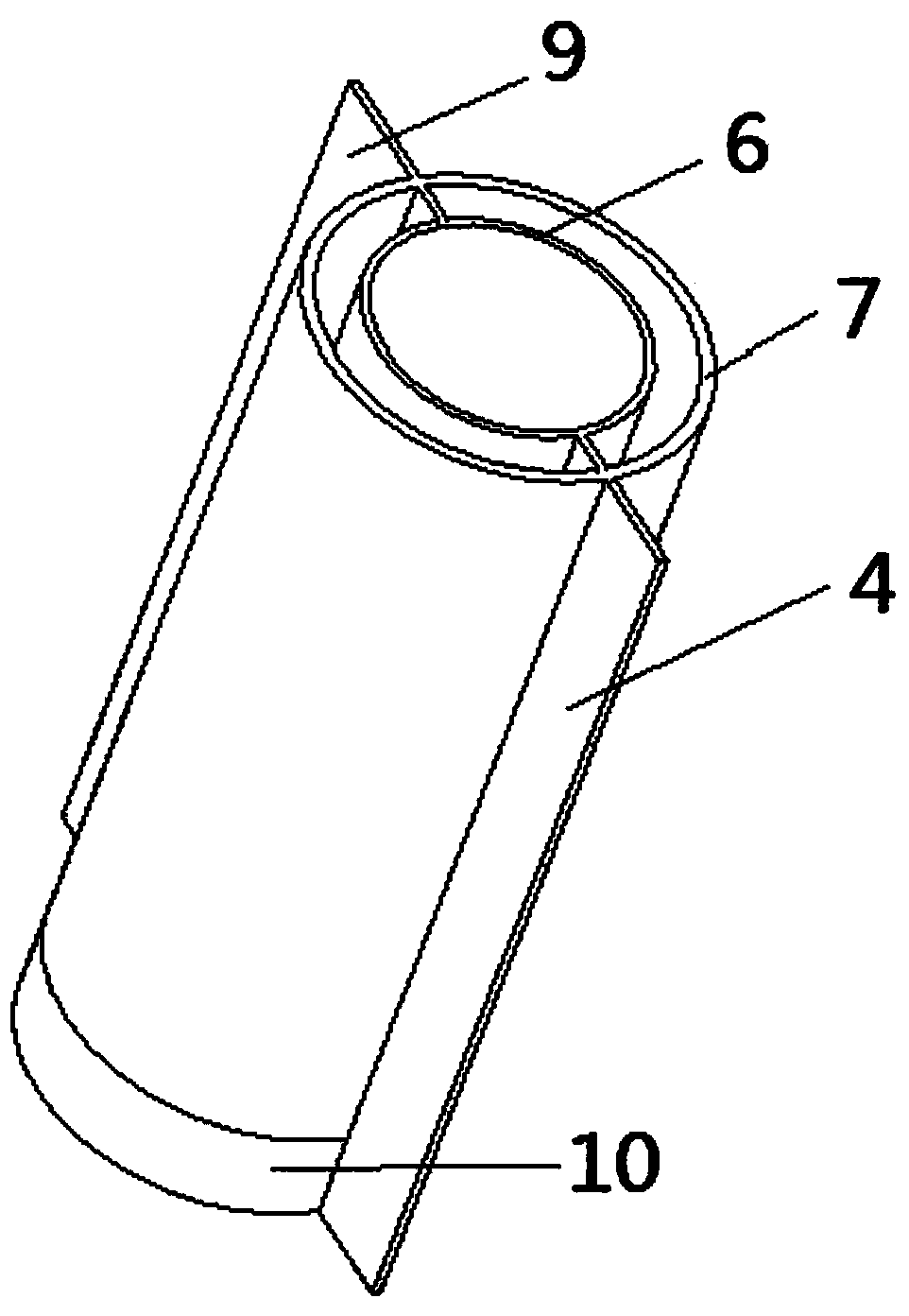

[0024] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a new type of casing buried pipe includes an inner pipe 6 and an outer pipe 8 arranged coaxially, a water outlet channel 2 is formed between the inner pipe 6 and the outer pipe 8, and the inner pipe 6 is a water inlet channel 1, The outer side of the inner pipe 6 is covered with an insulating pipe 7, and the insulating pipe 7 and the inner pipe 6 are arranged coaxially. Layer 3, the bottom of the outer tube 8 is sleeved with a head 5, the head 5 includes a tube part 502 and a sealing part 501 that are integrally formed, the tube part 502 is a thin-walled tubular structure, and the inner diameter of the tube part 502 is slightly smaller than The outer diameter of the outer tube 8, the outer tube 8 and the tube part 502 are in an interference fit; the sealing part 501 is an arc-shaped shell structure, which is located at the lower end surface of the tube part 502; The matching end is provided with a sealing co...

Embodiment 2

[0029] Same as Example 1, the difference is, as Figure 5 As shown, the first partition plate 4 and the second partition plate 9 are respectively provided with several first through holes 401 and several second through holes 901. The first through holes 401 and the second through holes 901 are arranged in a row. The first through hole 401 and the second through hole 901 can be round holes, square holes or holes with other geometric shapes. In this embodiment, round holes are used. The existence of the first through holes 401 and the second through holes 901 makes the first partition 4 It will not be sealed with the second partition 9, so the fluids on both sides will also pass through each other, and no pressure difference will be formed on both sides of the first partition 4 and the second partition 9, which reduces the first partition 4. and the pressure-receiving surface of the second separator 9, which plays a protective role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com