Jet-flow reflection temperature field testing method

A test method and temperature field technology, applied in the field of high temperature and high speed fluid flow research, to reduce the number of drives, improve data accuracy, and save test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing and aero-engine jet reflection test implementation case:

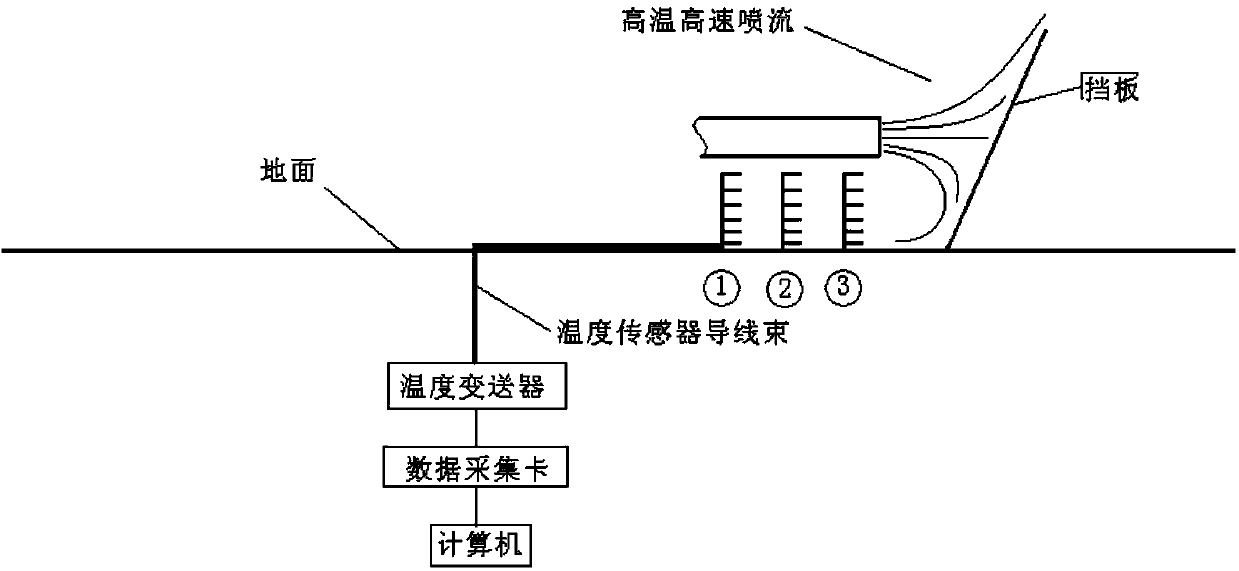

[0024] see figure 1 , is the functional block diagram of the test system. The velocity field test system consists of three sets of five-hole probes, scanning valves and data acquisition and recording systems. Each group of temperature measuring probes is installed on the soil-shaped test rake bracket according to the designed position.

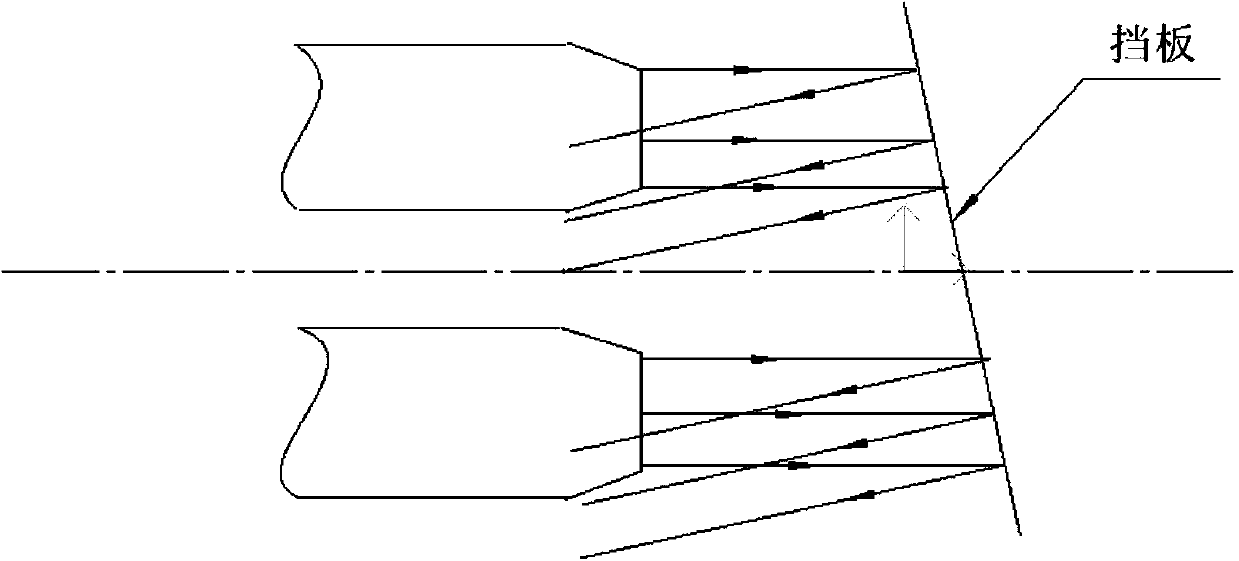

[0025] see figure 2 , is a schematic diagram of jet reflection under a 60° baffle. In the test, the size of the deflector is 3 × 6 meters, and the angle with the ground is 60°, and the angle with the plane of symmetry is 75°.

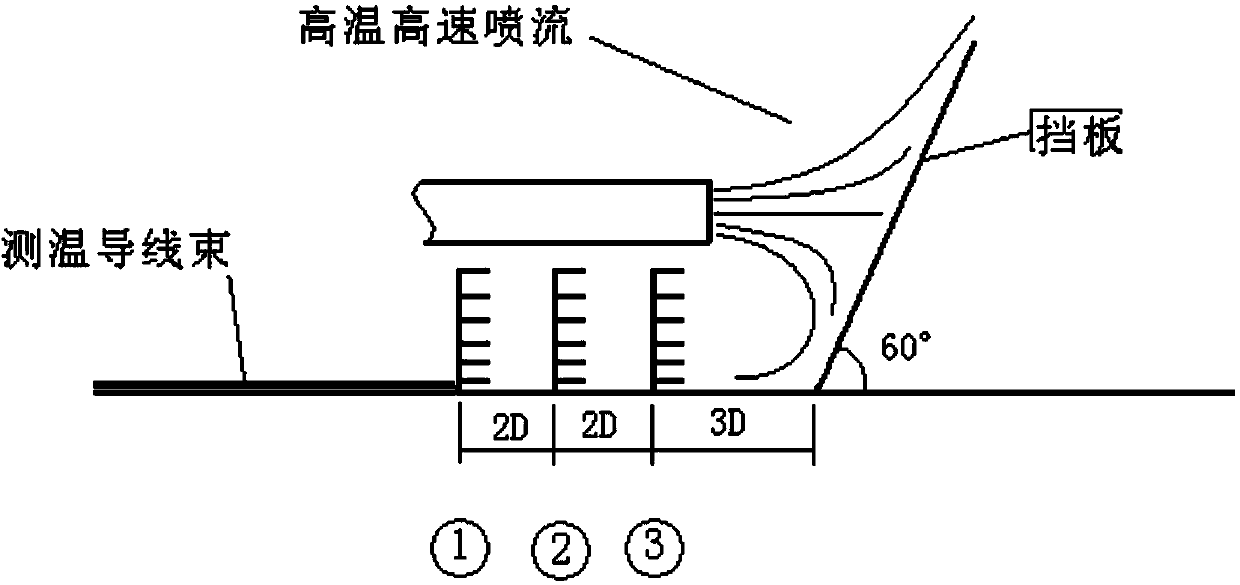

[0026] see image 3 , Schematic diagram of post-optimized rake arrangement. The baffle not only has a certain angle with the ground, but also deflects a certain angle with the symmetrical plane. Arranged as shown in the figure, the backflow of the left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com