A wind turbine blade condition monitoring method and system based on vibration detection and wireless signal transmission

A technology of vibration signals and blades, which is applied in the monitoring of wind turbines, wind turbines, engines, etc., can solve problems such as strength reduction and material stiffness reduction, and achieve the effect of fewer measuring points, low cost, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

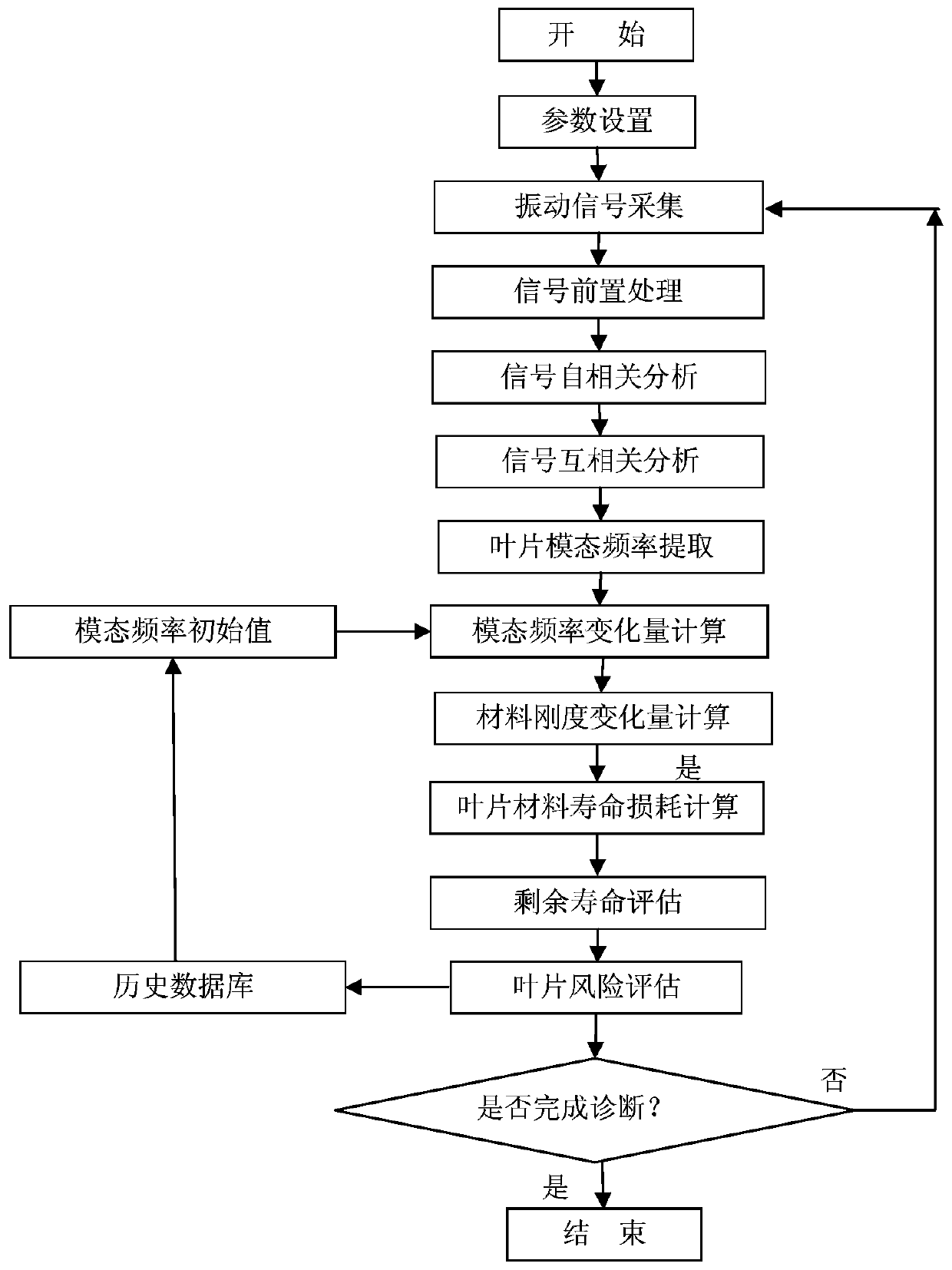

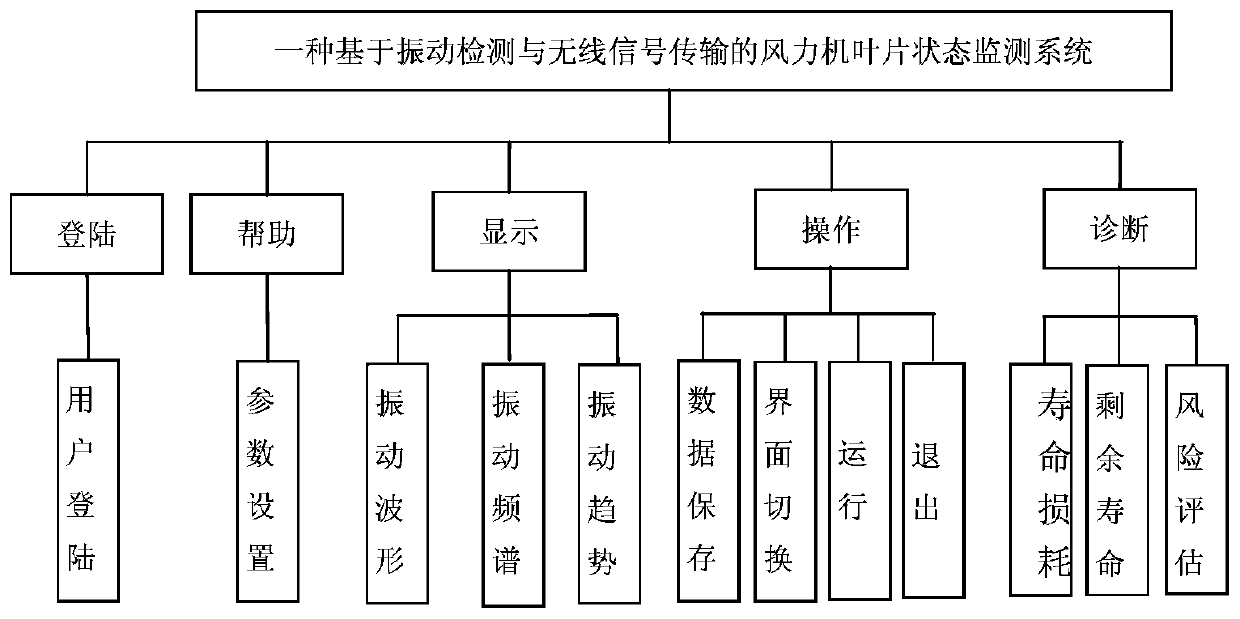

[0051] Such as figure 1 As shown, the wind turbine blade state monitoring method based on vibration detection and wireless signal transmission of the present invention is mainly based on blade modal frequency changes to complete online monitoring of blade material life loss, the steps are:

[0052] S1: Detect and collect vibration acceleration signals of wind turbine blades;

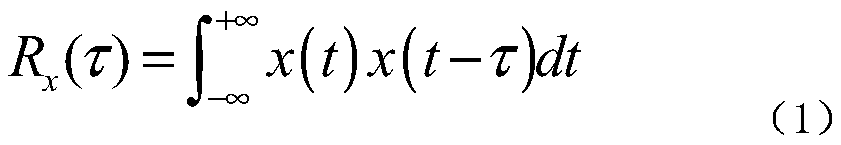

[0053] S2: Using the collected blade vibration acceleration signal, calculate the actual low-order modal frequency of the blade;

[0054] S3: Calculate the square difference between the square of the actual low-order modal frequency of the blade and the modal frequency under the same operating condition when the new unit is put into operation;

[0055] S4: Use the relative change of the square difference of the modal frequency to obtain the relative change of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com